Part conveying device for engineering machinery production and machining

A technology of construction machinery and conveying device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

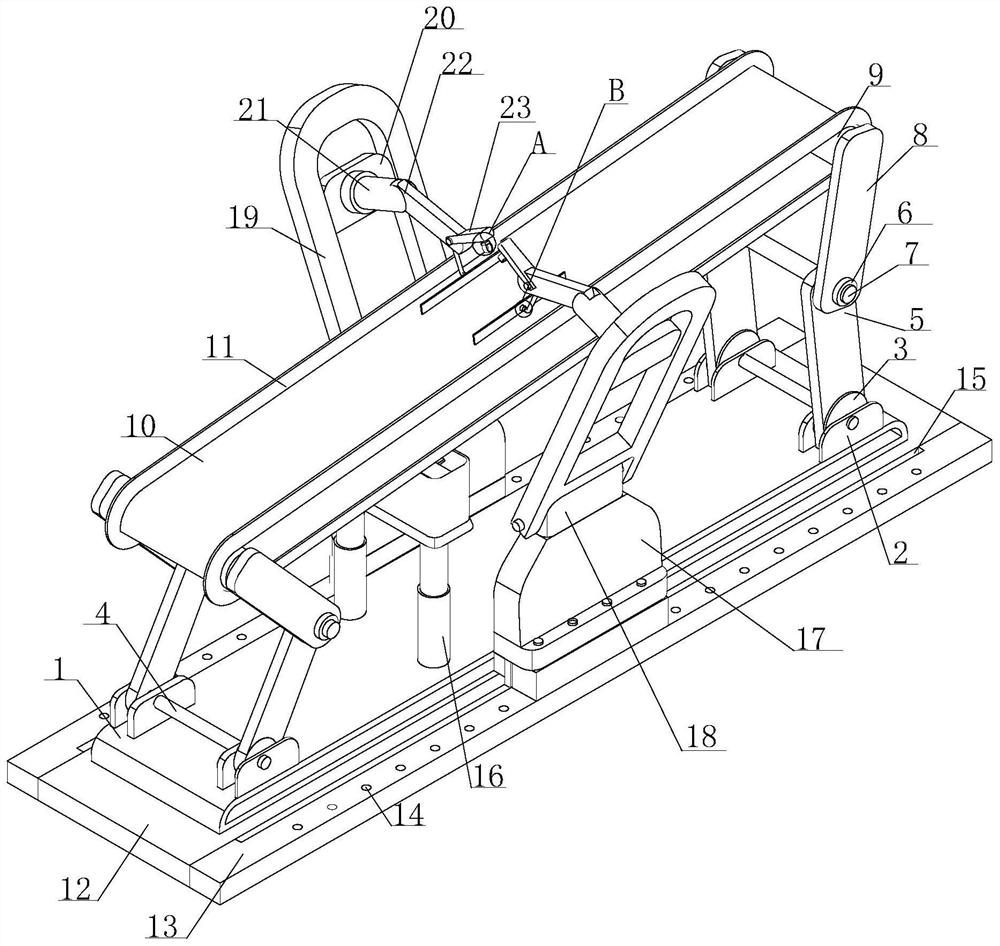

[0041] see figure 1 , the present invention provides a technical solution: a parts conveying device for construction machinery production and processing, including a support platform 1, a limiting plate 2 is arranged on the top of the supporting platform 1, and a rotating plate 3 is movably connected to the inner wall of the limiting plate 2. The inside of the plate 3 is provided with a linkage shaft-4, the outer wall of the linkage shaft-4 is fixedly connected with the inner wall of the rotating plate 3, and the outer wall of the end of the rotating plate 3 away from the support table 1 is fixedly connected with the adjusting plate-5, and one end of the adjusting plate-5 Fixedly connected with the outer wall of the rotating plate 3, the other end of the adjusting plate one 5 is provided with a linkage shaft two 7, and the two ends of the linkage shaft two 7 are flexibly connected with the inner wall of the adjusting plate one 5.

[0042] The outer wall of the linkage shaft 2 ...

Embodiment 2

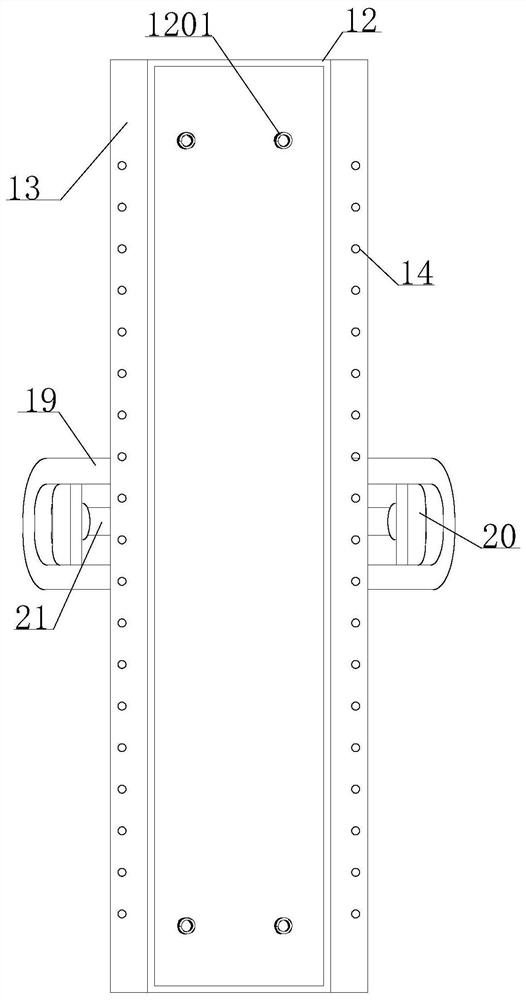

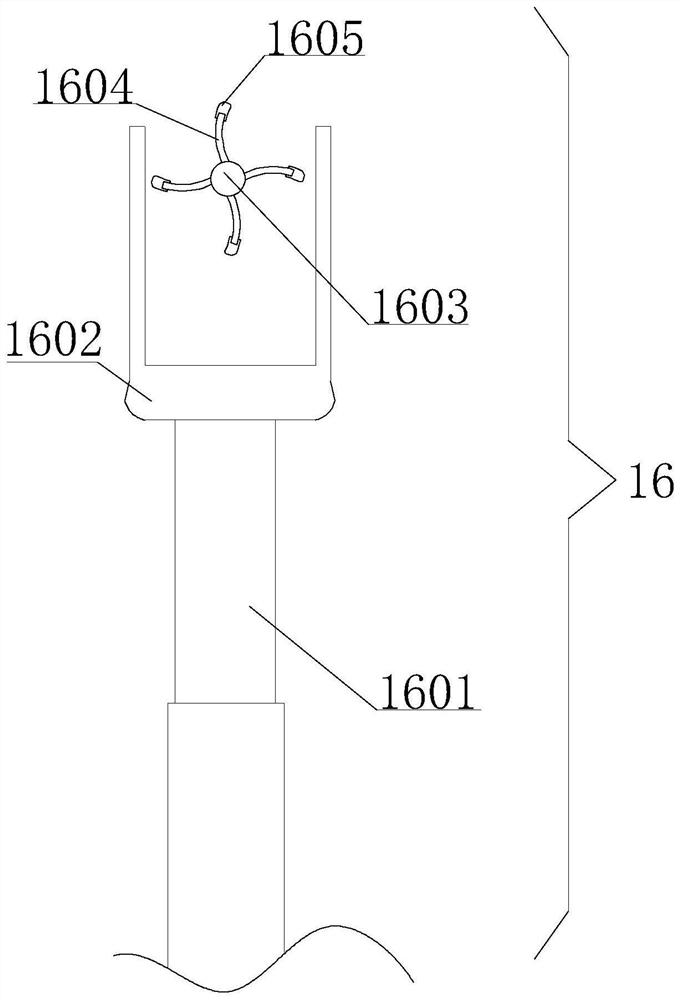

[0045] see Figure 1-7 , the present invention provides a technical solution: the bottom of the support platform 1 is provided with an installation base 12, the top of the installation base 12 is fixedly connected with the bottom of the support platform 1, the bottom of the installation base 12 is provided with a shock absorbing spring 1201, and the shock absorbing spring 1201 Fixedly installed on the inner wall of the mounting base 12, the two ends of the mounting base 12 are fixedly connected with a fixed table 13, the outer wall of the fixed table 13 is provided with a threaded hole 14, and the end of the threaded hole 14 near the mounting base 12 is provided with a chute 15, The chute 15 is opened on the top of the fixed platform 13; the top of the fixed platform 13 is movably equipped with a driving device 17, and the inside of the driving device 17 includes a support block 1701, and the bottom of the support block 1701 is provided with a connecting plate 1702, and one end...

Embodiment 3

[0048] see Figure 1-5 , the present invention provides a technical solution: the top of the driving device 17 is fixedly mounted with a hinged block 18, the inner wall of the hinged block 18 is movably connected with a hinged rod, the two ends of the hinged rod are fixedly mounted with an adjustment frame 19, and the inside of the adjustment frame 19 is set There is a mounting plate 20, the outer wall of the mounting plate 20 is flexibly connected with the inwall of the adjusting frame 19, the outer wall of the mounting plate 20 is fixedly installed with a mounting seat, and the inwall of the mounting seat is fixedly equipped with a fixed rod 21; the fixed rod 21 is arranged away from one end of the mounting seat Movable rod 22 is arranged, and one end of movable rod 22 is movably connected with the inwall of fixed rod 21, and the other end inwall of movable rod 22 is movably connected with rotary knob, and the outer wall of rotary knob is fixedly equipped with adjusting colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com