Heather-grey spun yarns capable of showing multiple black and white alternated and different-length patterns

A pattern, black and white technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of low degree of simulation, troublesome weaving procedures of black and white yarn, etc., and achieve the effect of improving work efficiency and reducing fabric cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

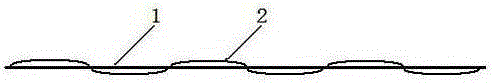

[0010] Example 1: Connect 10% of the white polyester yarn 1 to the yarn guide on the texturing machine, and then connect 90% of the black polyester yarn 2 to the yarn guide on the same texturing machine. The polyester filaments pass through the nozzle and are compounded and interwoven into a dark heather gray spinning yarn with a winding structure.

Embodiment 2

[0011] Embodiment 2: 90% of the white polyester yarn 1 is connected to the yarn guide on the texturing machine, and then 10% of the black polyester yarn 2 is connected to the yarn guide on the same texturing machine, and two different colors are obtained after starting the machine. The polyester filaments pass through the nozzle and are compounded and interwoven into a light heather gray spinning yarn with a winding structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com