Polyurethane rubber sound and vibration insulation cushion and use method thereof

The technology of polyurethane rubber and vibration isolation pad is applied in sound insulation and vibration isolation. It can solve the problems of high price and poor attraction effect, and achieve the effect of low cost, strong sound absorption effect and good shock absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

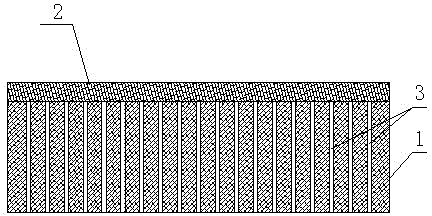

[0016] Such as figure 1 , the present invention relates to a polyurethane rubber sound-insulating and shock-insulating pad, which is a double-layer structure of the bottom layer 1 and the surface layer 2, the thickness of the surface layer 2 is 3-8mm, and 5mm is the best, and the surface layer material is made of waste polyurethane rubber particles Made; the bottom layer 1 is also made of waste polyurethane rubber particles, with a thickness of 40-50mm, preferably 45mm, and the bottom layer 1 is evenly distributed with a number of through holes 3 from top to bottom.

[0017] For the sake of aesthetic effect and laying is easy to distinguish, the bottom layer and surface layer materials have different colors, and the surface layer is made of colored waste polyurethane rubber particles.

[0018] How to use: When laying the bottom surface of the central air-conditioning machine room, lay the bottom concrete first, and then lay the polyurethane rubber sound-proof and shock-proof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com