Flight test equipment installation system and method

A technology for flight testing and installation systems, which is applied to aircraft component testing, mechanical equipment, equipment for loading and unloading cargo, etc., and can solve time-consuming and complicated problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

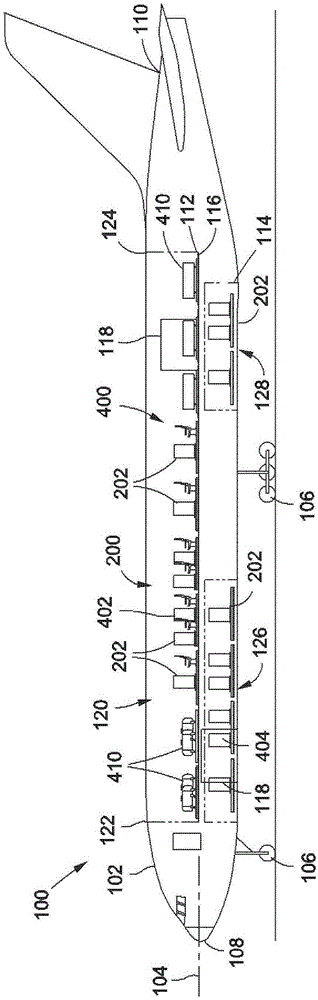

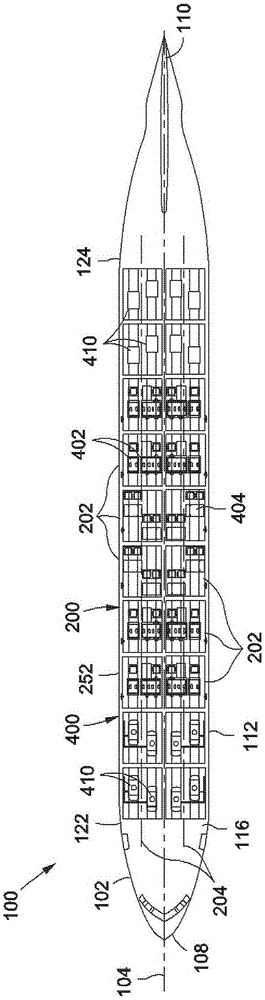

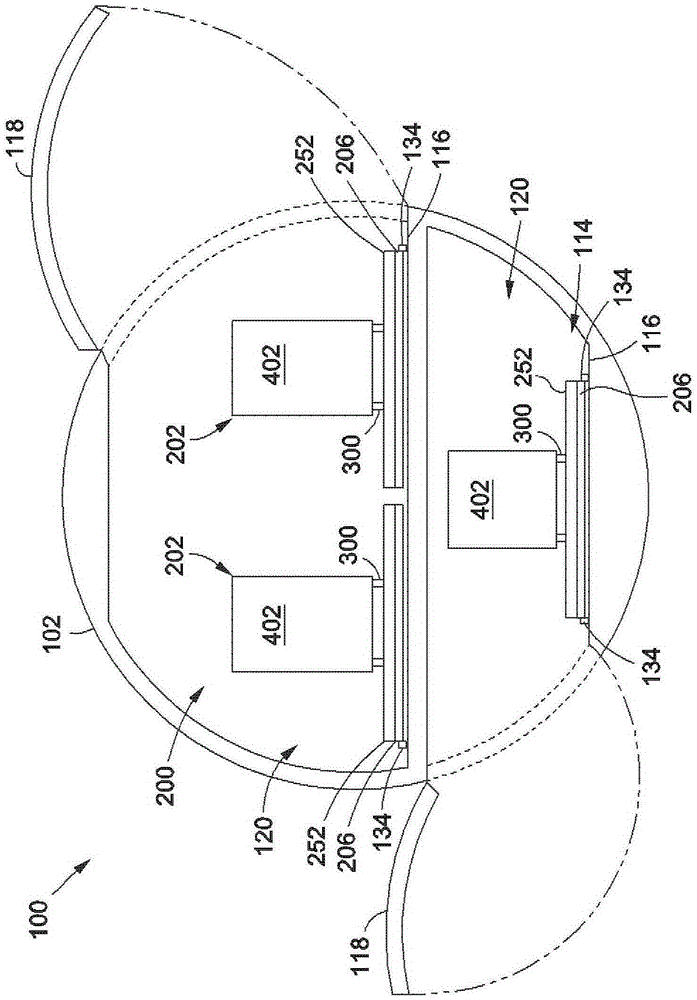

[0032] Referring now to the drawings, in which are shown for purposes of illustration various embodiments of the present disclosure, figure 1 Shown in is a side view of aircraft 100 . The aircraft may include a fuselage 102 supported on landing gear 106 . Fuselage 102 may have nose 108 at a forward end and empennage 110 at aft end 124 . The longitudinal axis 104 may extend between a nose 108 and an empennage 110 . Aircraft 100 may be loaded with a plurality of pallet assemblies 202 , which may be secured to cargo floor 116 on main deck 112 and / or cargo deck 114 of aircraft 100 . The cargo deck 114 may be divided into a forward cargo compartment 126 and an aft cargo compartment 128 . The pallet assemblies 202 may each contain one or more units of flight test equipment 402 that collectively make up the flight test equipment assembly 400 .

[0033] Each unit of flight test equipment 402 may be fixedly mounted to pallet assembly 202 . Pallet assembly 202 may be loaded into ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com