a shunt

A shunt, current technology, applied in instruments, voltage/current isolation, measurement devices, etc., can solve the problems of low precision and high power consumption, and achieve the effect of small thermal volume, reduced use, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

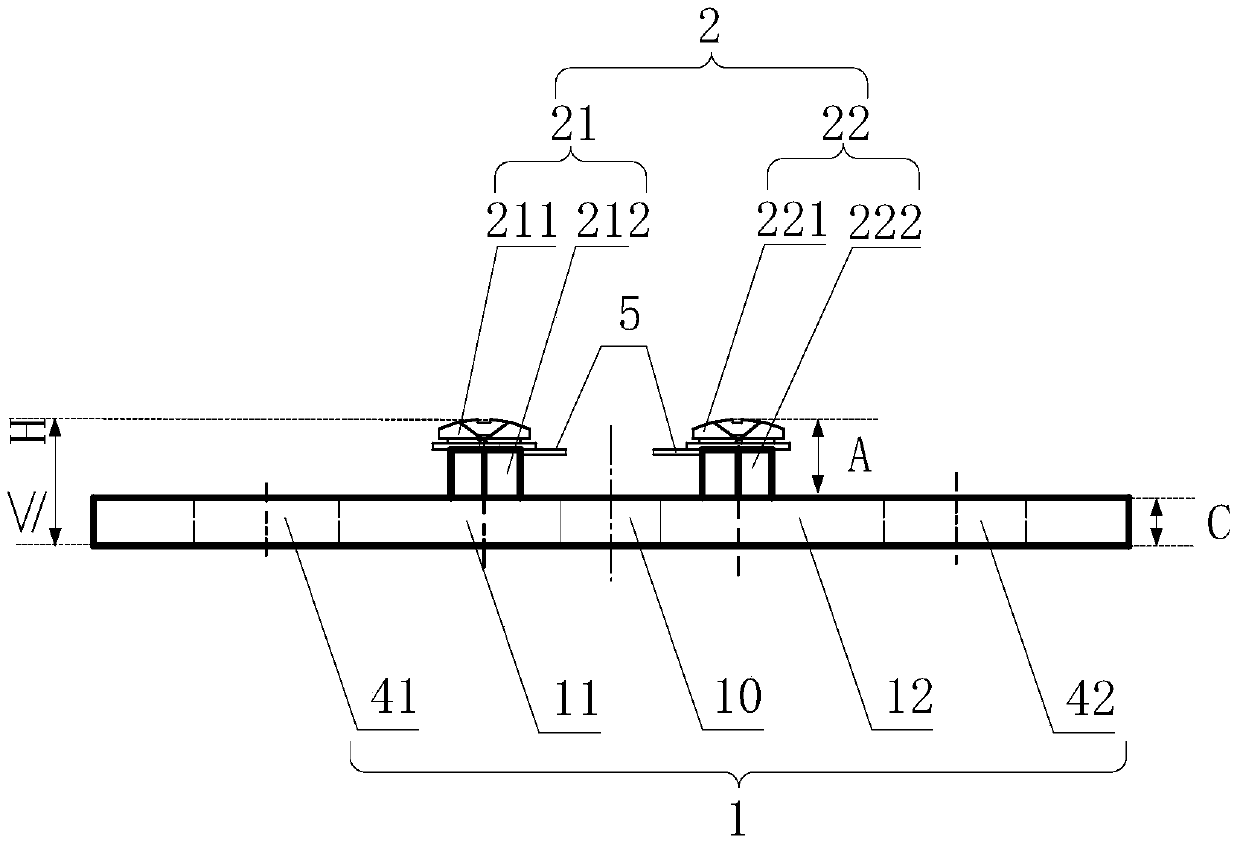

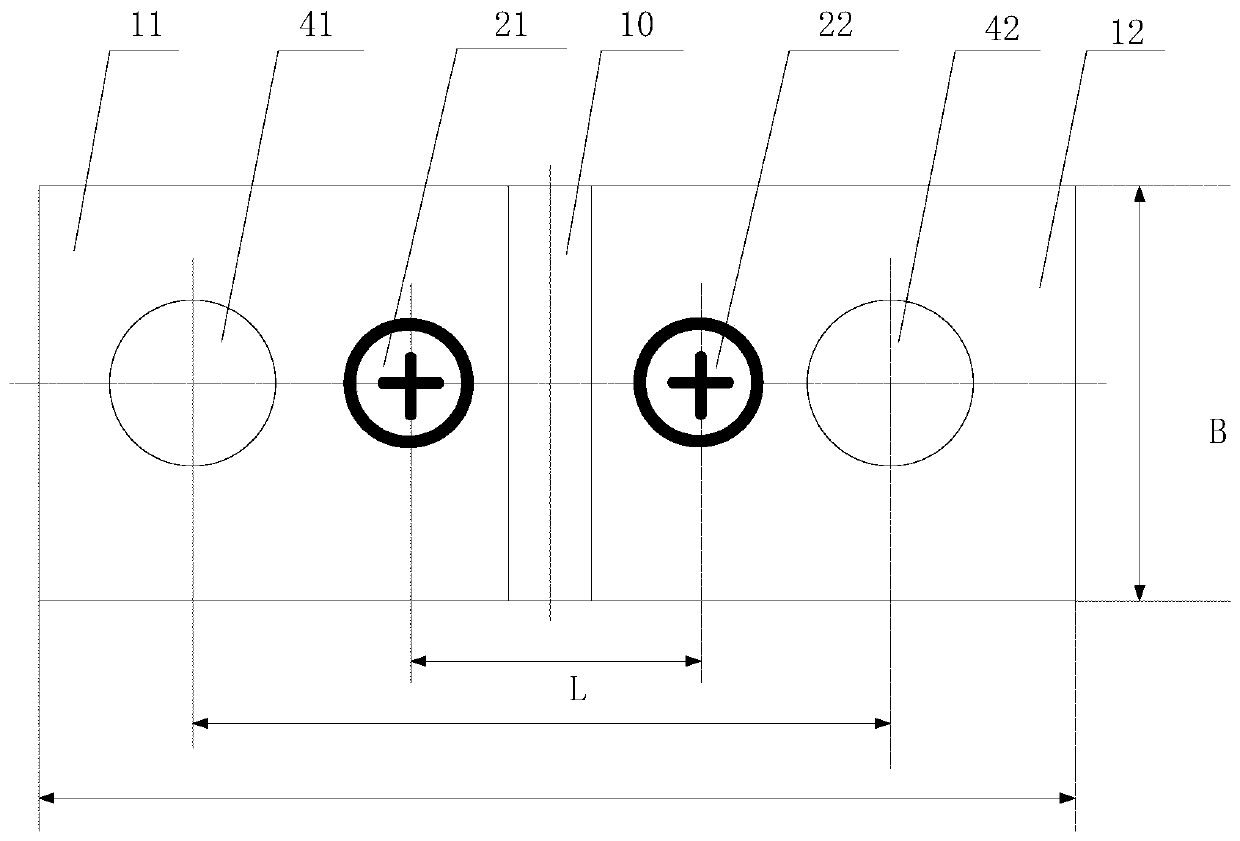

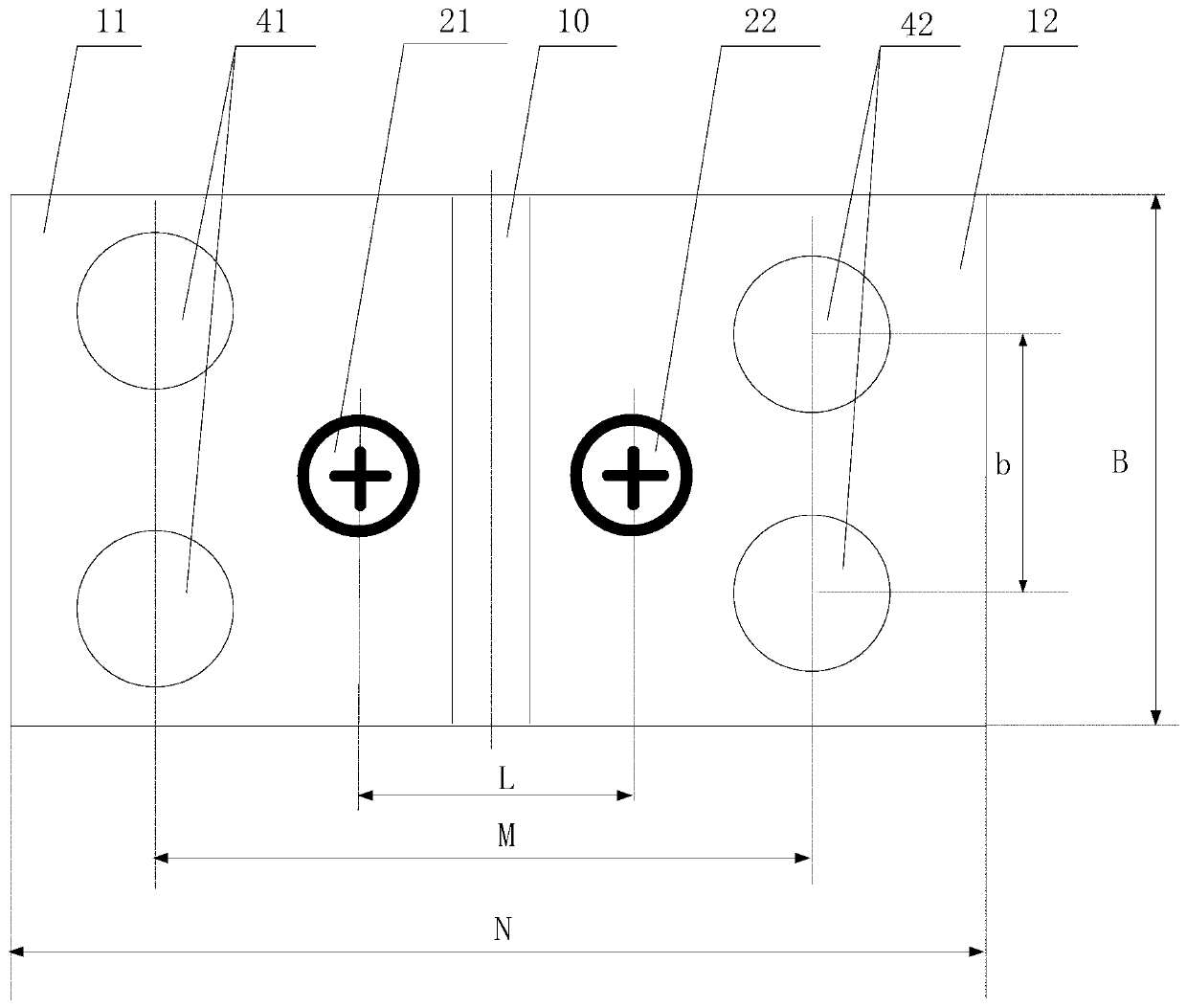

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0027] The main body of the shunt of the present invention adopts electron beam welding to combine the resistive material manganese copper plate and the conductive material red copper plate into one body, which not only utilizes the thermal stability of the manganese copper plate to ensure that the precision of the shunt when working meets the technical requirements, but also utilizes the excellent quality of copper. Conductivity is used to increase the accuracy of the shunt during measurement, thereby realizing a shunt with high precision and low power consumption.

[0028] figure 1 and figure 2 It is a schematic structural diagram of a flow divider according to an embodiment of the present invention. figure 1 main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com