A fast-response armored resistance temperature sensor and its packaging method

A temperature sensor and fast response technology, applied in the field of sensors, can solve the problems of large thermal resistance, slow thermal response speed and small thermal conductivity of thermistors, and achieve the effect of fast heating speed, fast response speed and small thermal volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

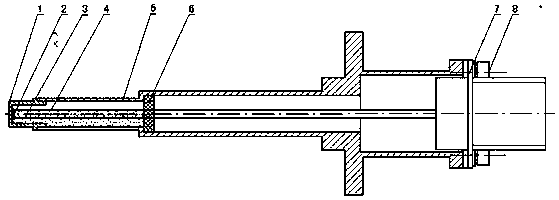

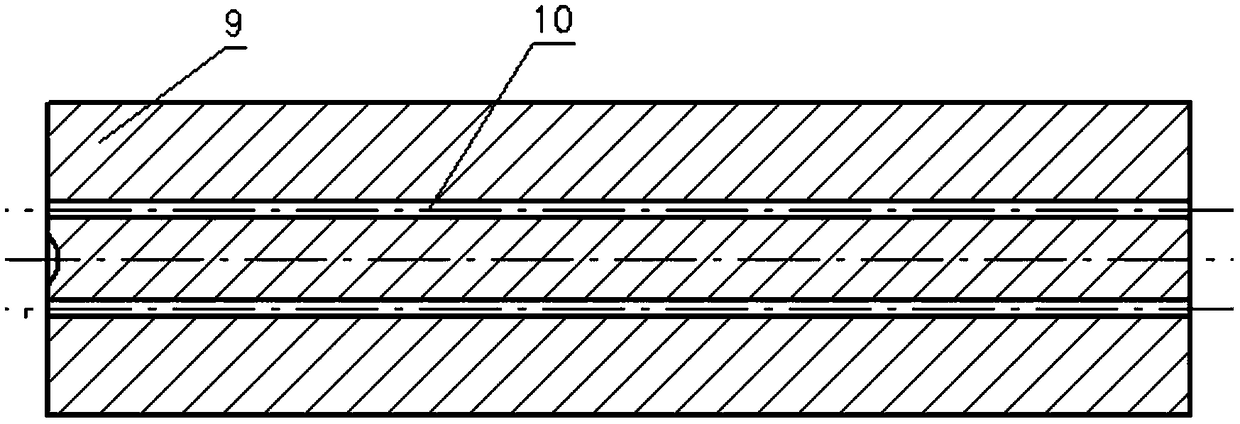

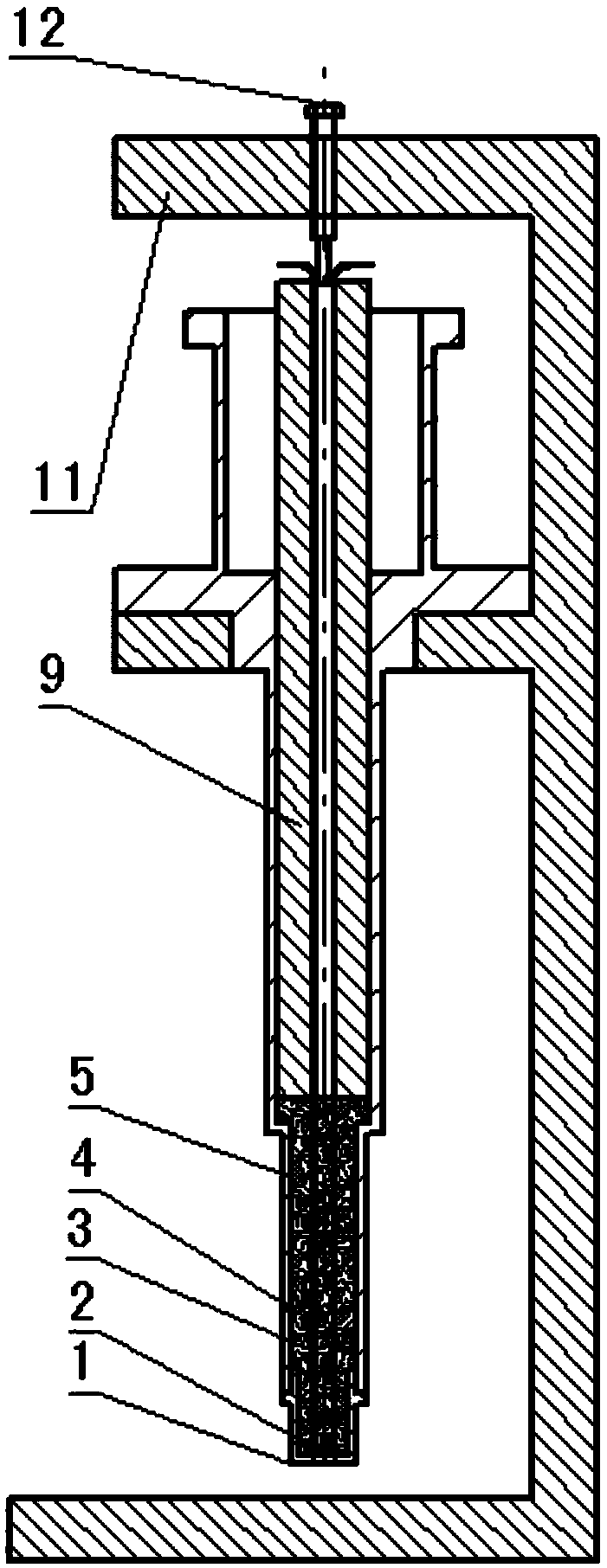

[0031] see figure 1 , a fast-response armored resistance temperature sensor, including a housing 5, the tail end of the housing 5 is fixed with a connector 7 through a sensor screw 8, the housing 5 and the connector 7 form a closed cavity, and a slave connector is arranged in the sealed cavity The plug-in 7 extends out to the wire 4 at the head end of the airtight cavity, and the inside of the shell 5 is welded with a silver sheath 1, and the wire 4 is connected to the thermistor 2, and the thermistor 2 is in contact with the silver sheath 1, and the silver sheath 1 and the shell 5 The interior is filled with nano-aluminum nitride 3, and the nano-aluminum nitride 3 is sealed on the head end of the shell 5 through a high-temperature sealant 6, and the thermistor 2 is pasted together with the inner end surface of the silver sheath 1 through a heat-conducting glue.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com