Assembled conductor and manufacturing method for assembled conductor

A technique for gathering wires and a manufacturing method, which is applied in the field of gathering wires, can solve the problem that the insulating film 803 cannot have a thickness, and achieve the effect of suppressing distortion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

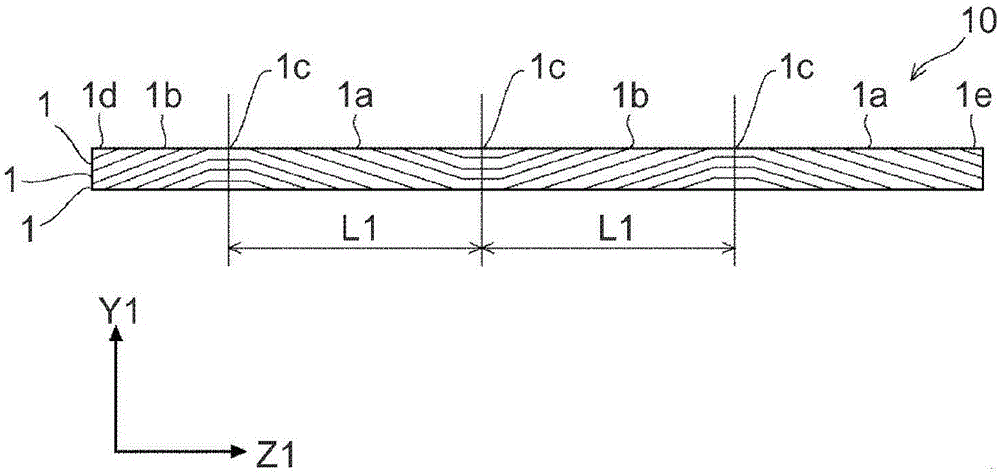

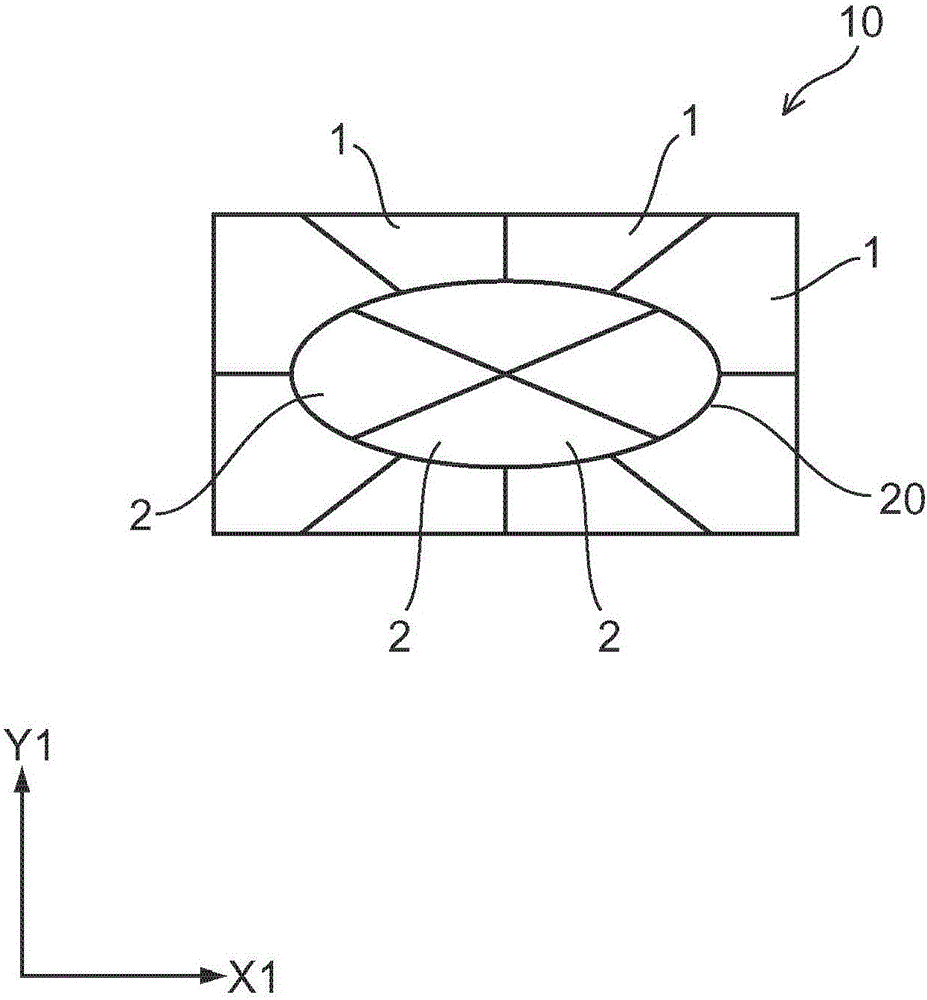

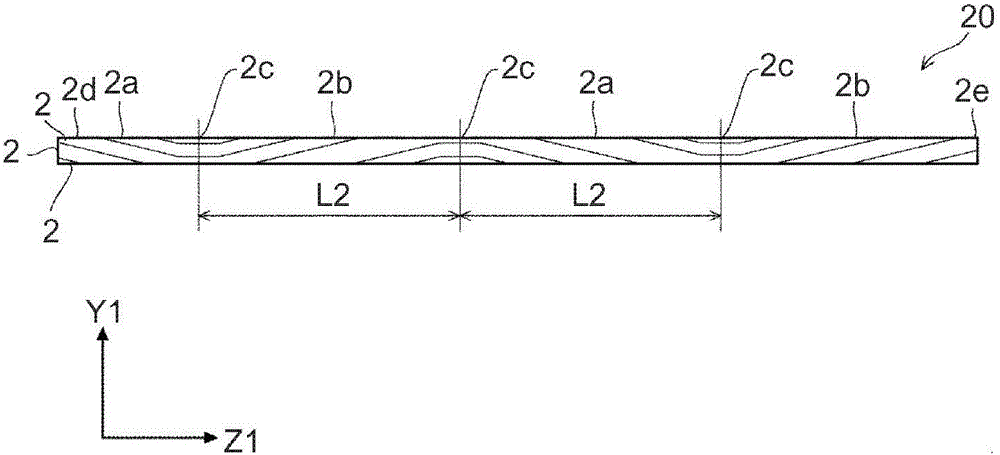

[0039] The first embodiment: (collection wire) refer to Figure 1 to Figure 4 , to describe the collective wire according to the first embodiment. figure 1 is a side view of the collective wire according to the first embodiment. figure 2 is a sectional view of the collective wire according to the first embodiment. image 3 is a side view of the center wire according to the first embodiment. Figure 4 is a sectional view of the center wire according to the first embodiment. exist figure 2 and Figure 4 In , for simplicity, the shadows are appropriately omitted.

[0040] Such as figure 1 and figure 2 As shown, the collective wire 10 includes a central wire bundle 20 and peripheral wires 1 arranged around the central wire bundle 20 . The collective wire 10 is, for example, a linear body having a given cross-sectional shape such as a rectangular cross-section. The cross-sectional shape of the collective wire 10 can be formed by rolling as described later.

[0041] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com