Patents

Literature

94results about How to "Inhibition Manufacturing Method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

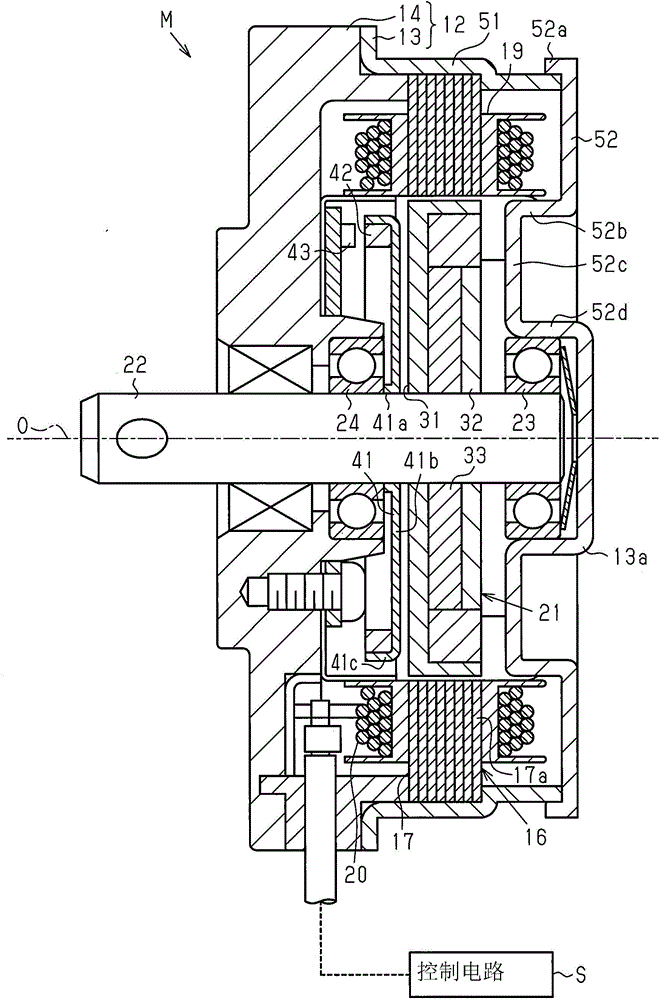

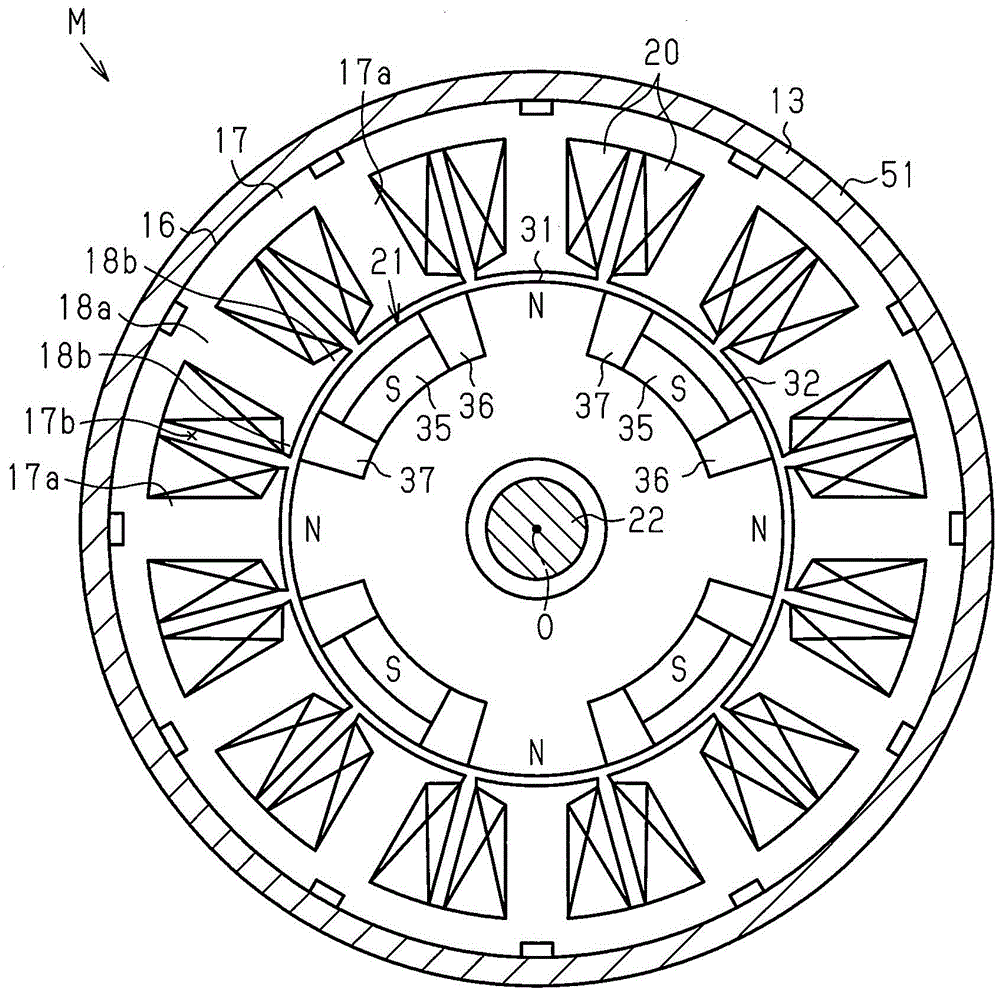

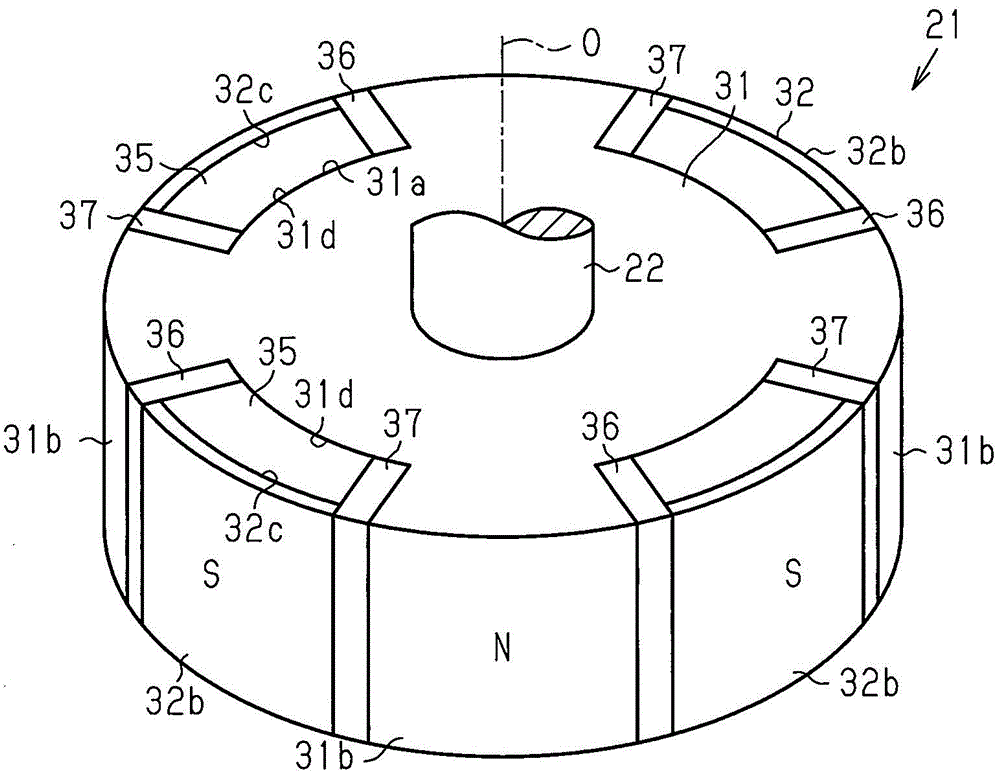

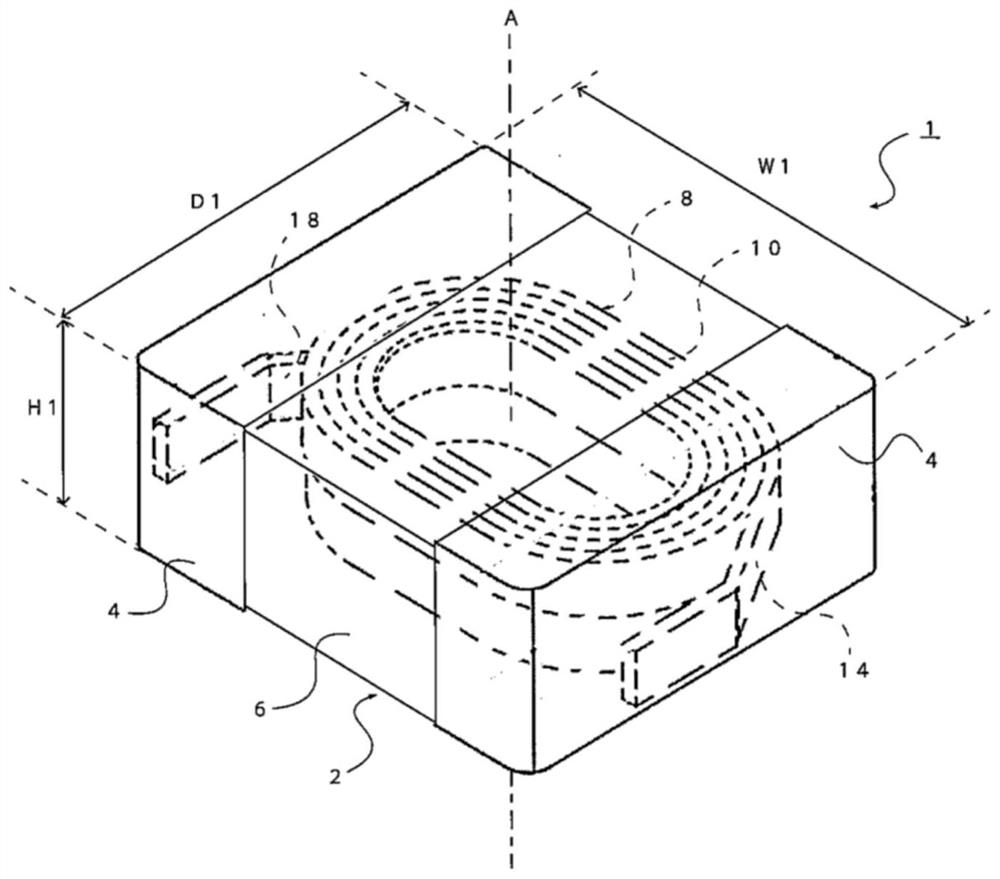

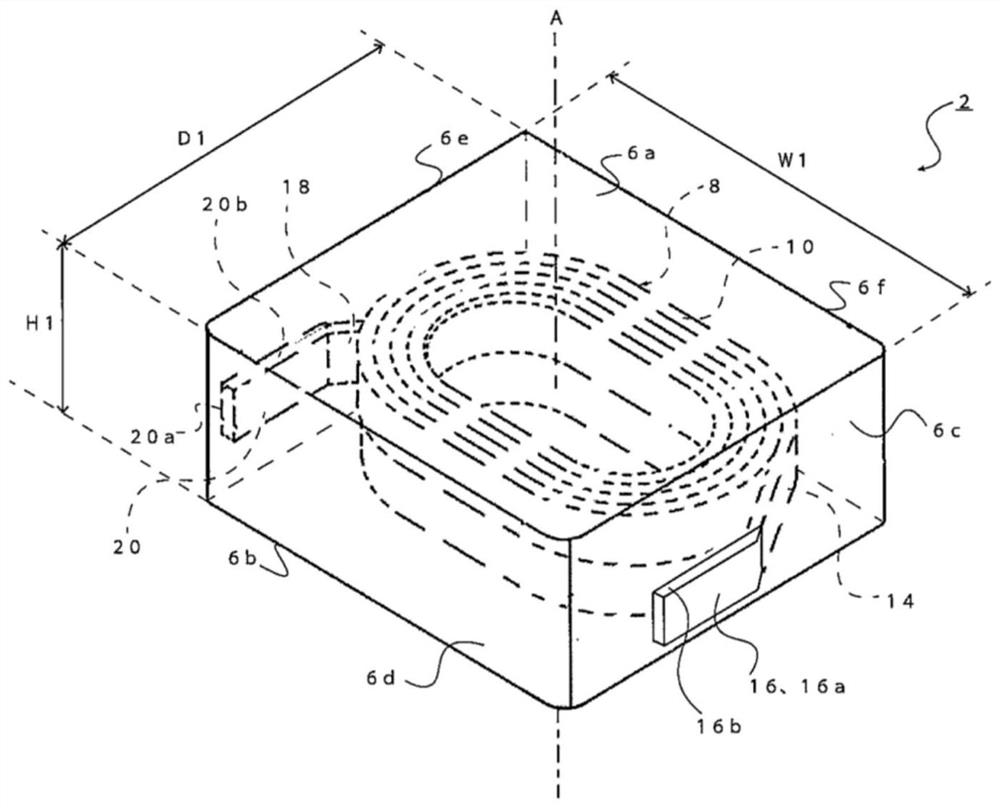

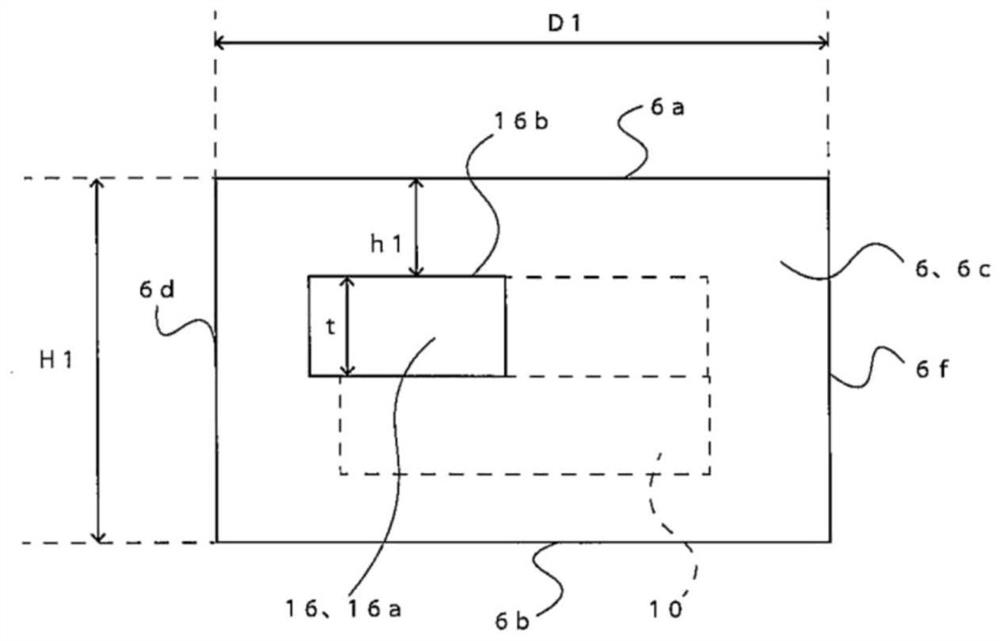

Motor, rotor and method for manufacturing rotor

ActiveCN104811005AInhibition Manufacturing MethodMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetic polesEngineering

A motor includes a stator, a rotor, and a case. The stator includes a stator core and windings. The rotor is provided inside the stator. The rotor includes first and second rotor cores and a field magnet. The first and second rotor cores each includes a core base and claw-shaped magnetic poles. The core bases are opposed to each other and the claw-shaped magnetic poles of the first and second rotor cores are alternately disposed in a circumferential direction. The field magnet is disposed between the core bases in the axial direction. The field magnet is magnetized in the axial direction so as to cause the claw-shaped magnetic poles of the first rotor core and the second rotor core to function respectively as first magnetic poles and second magnetic poles. At least part of an end part of the case in the axial direction is made of a non-magnetic body.

Owner:DENSO CORP

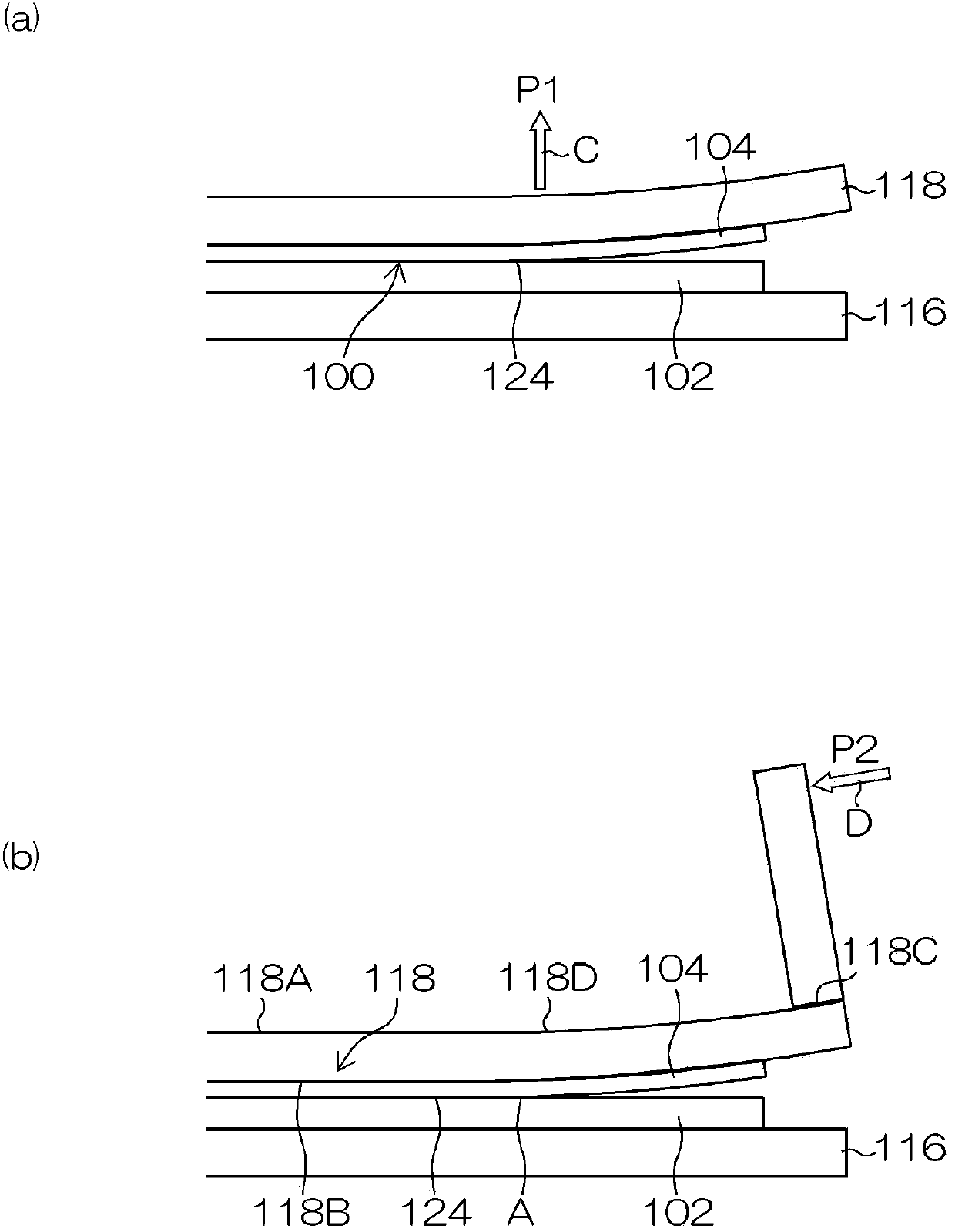

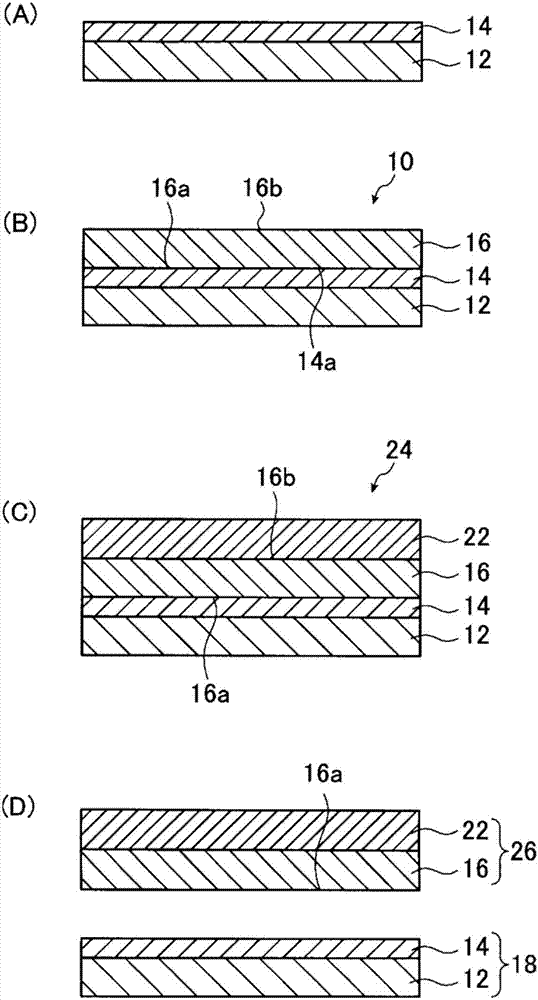

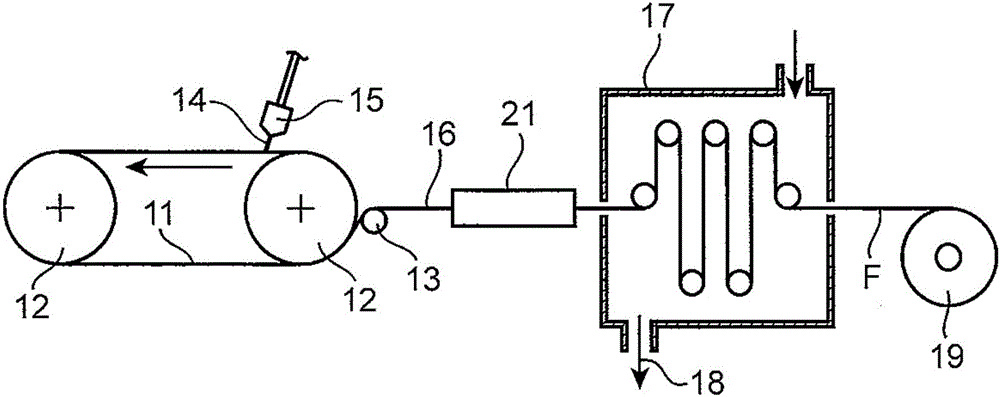

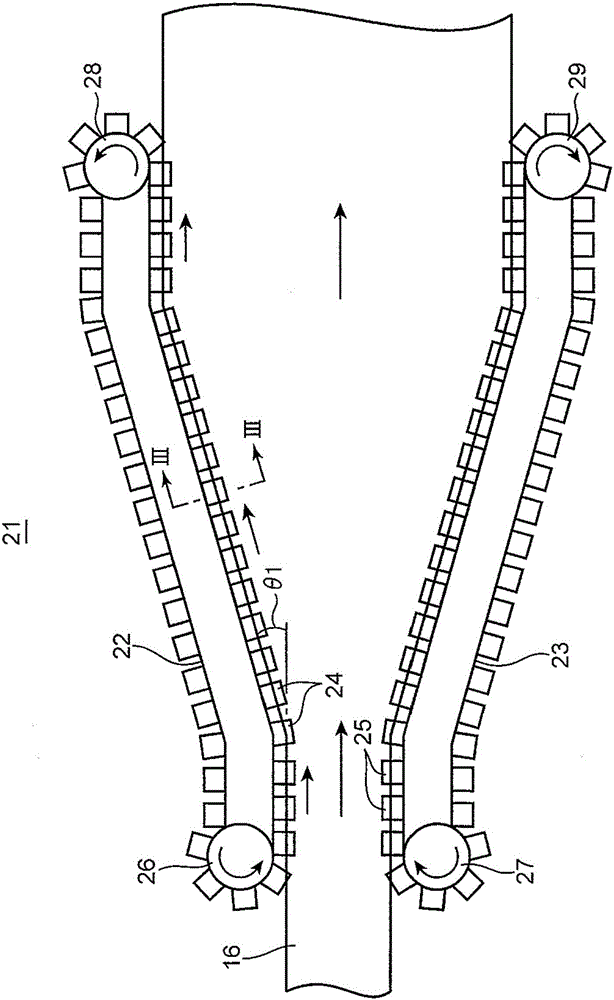

Peeling device and manufacturing method for electronic device

InactiveCN102983062AAvoid breakingInhibition Manufacturing MethodLamination ancillary operationsFinal product manufactureBorder lineEngineering

The invention provides a peeling device and a manufacturing method for electronic devices. The peeling device peels a substrate and an interface of a reinforcing plate which reinforces the substrate from an end to the other end in sequence. The peeling device comprises a bearing component which supports the above substrate and a first main surface of a laminate of thereinforcing plate, a flexible plate which absorbs a second main surface of the laminate, a plurality of movable bodies which are fixed on the flexible plate at intervals and can independently move relative to the bearing component, and a control device which controls movement of the plurality of movable bodies. The control device controls movement of the plurality of movable bodies in a following method. When a straight-line distance between two ends of a border line of a part which is peeled off theinterface and a part which is not peeled off theinterface is longest, the above border line forms a bending shape raised to the rear of a moving direction of the border line.

Owner:ASAHI GLASS CO LTD

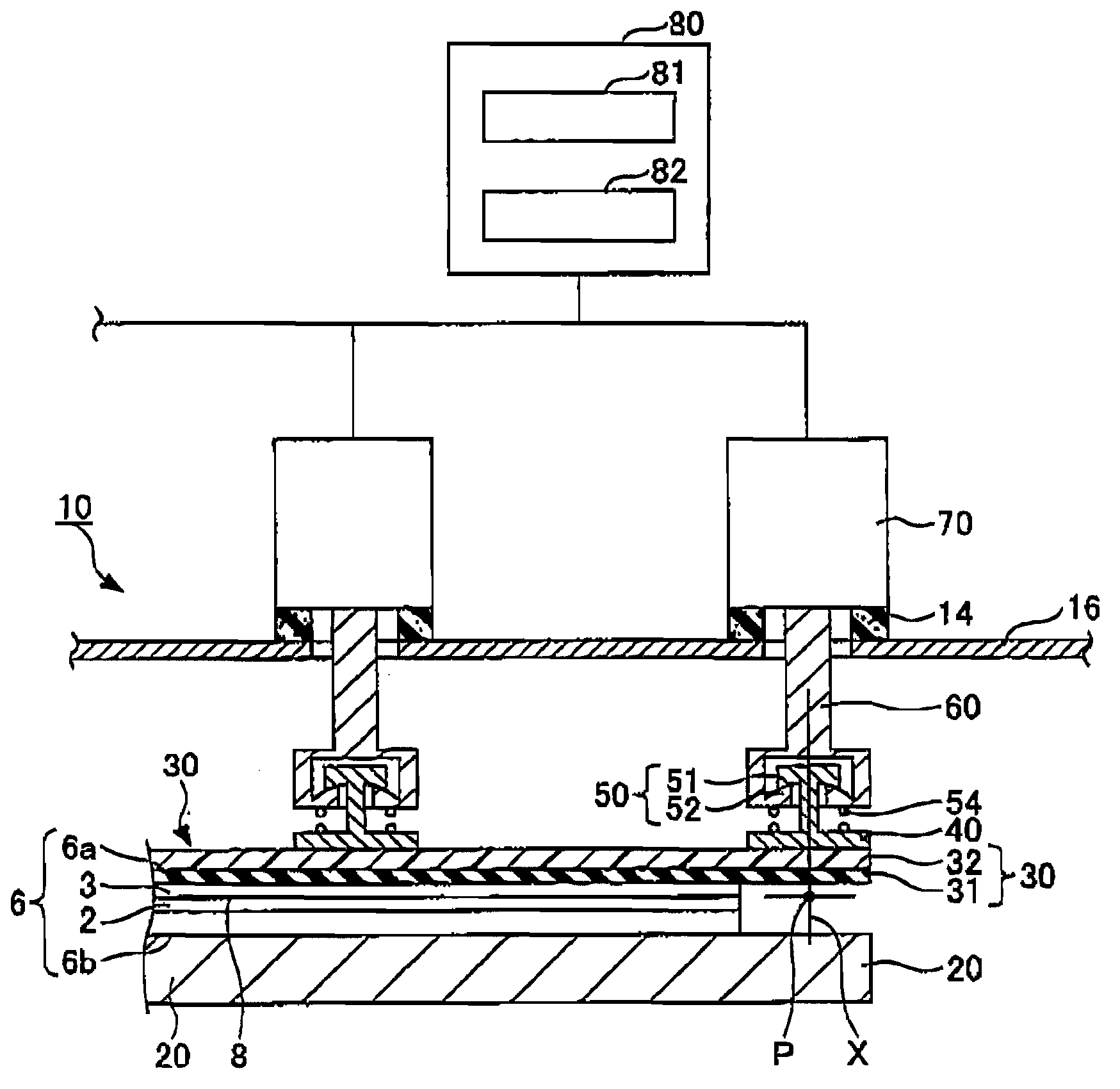

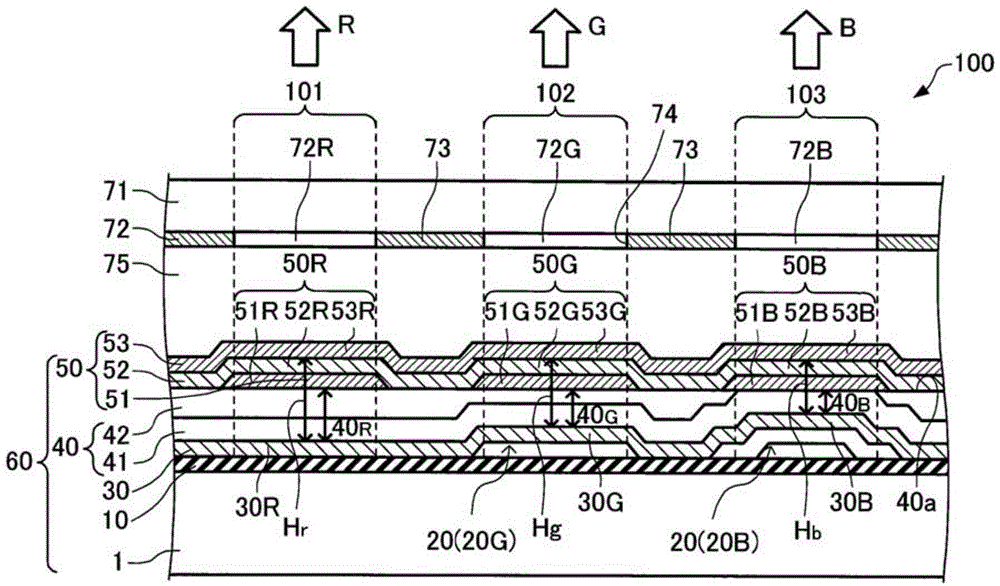

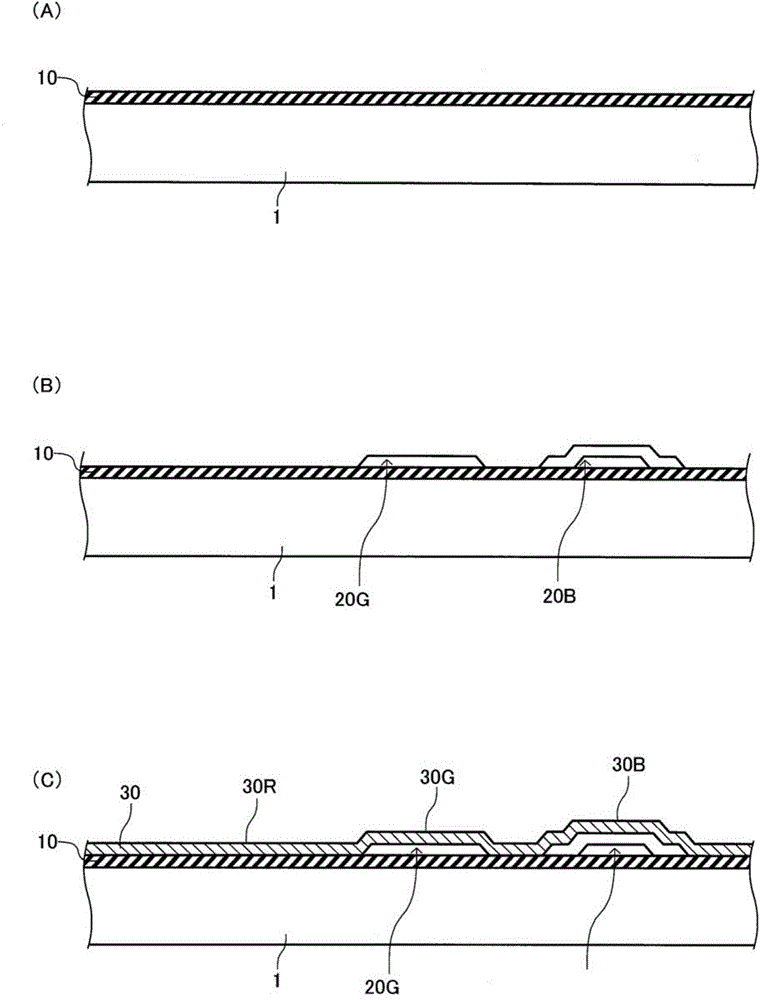

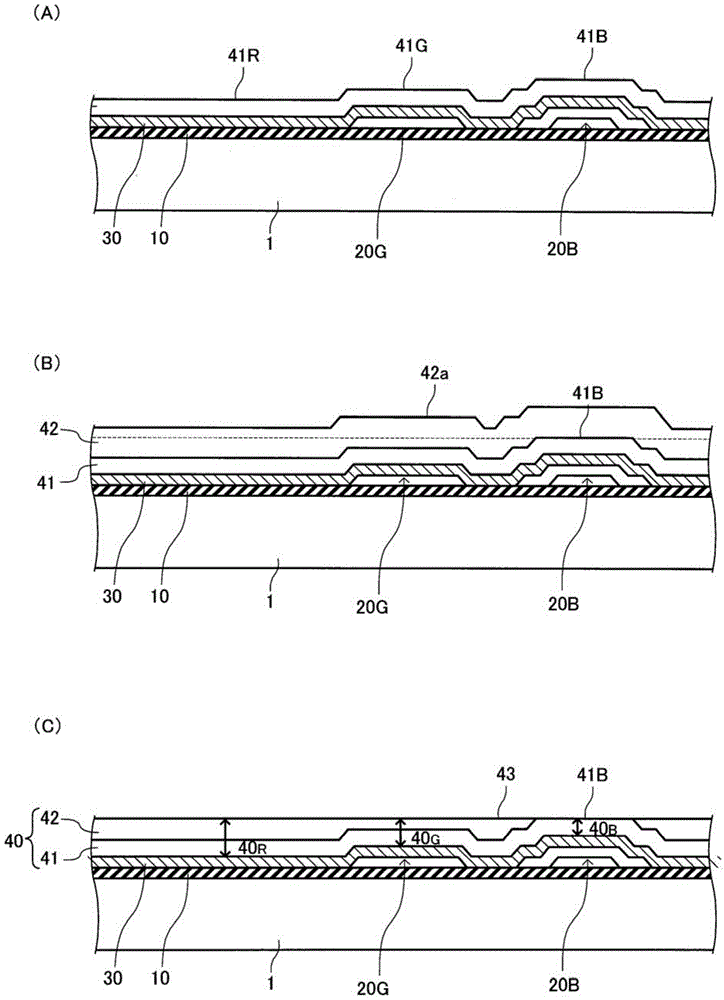

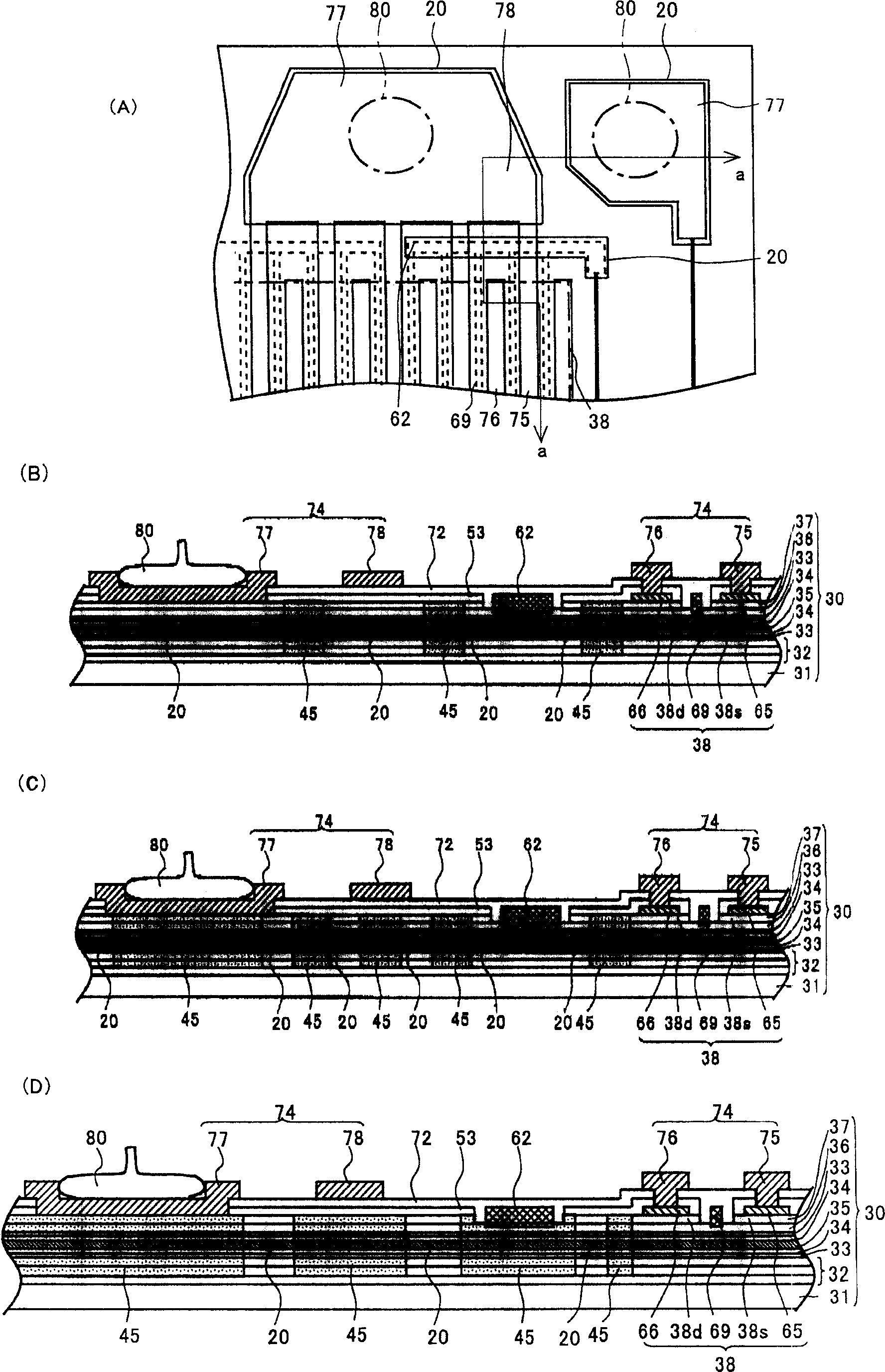

Fabrication method for organic EL device

InactiveCN104078422AInhibition Manufacturing MethodImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOrganic electroluminescence

The fabrication method for an organic EL device according to the invention includes: forming a third insulating layer on a first insulating layer; removing the third insulating layer in a first pixel region by etching the third insulating layer; forming a second insulating layer that has different thicknesses in a first pixel and a second pixel and has a flat first surface by forming a precursor insulating layer to continuously cover a first reflection film and a second reflection film and then planarizing an upper surface of the precursor insulating layer; and forming a first pixel electrode and a second pixel electrode on the first surface of the second insulating layer. The first insulating layer is slower in the rate at which the layer is removed by etching than the third insulating layer.

Owner:SEIKO EPSON CORP

Peeling device and peeling method of substrate, and manufacturing method of electronic device

ActiveCN103972142AInhibition of rupturePrevent peelingSemiconductor/solid-state device manufacturingArticle deliveryEngineering

Owner:ASAHI GLASS CO LTD

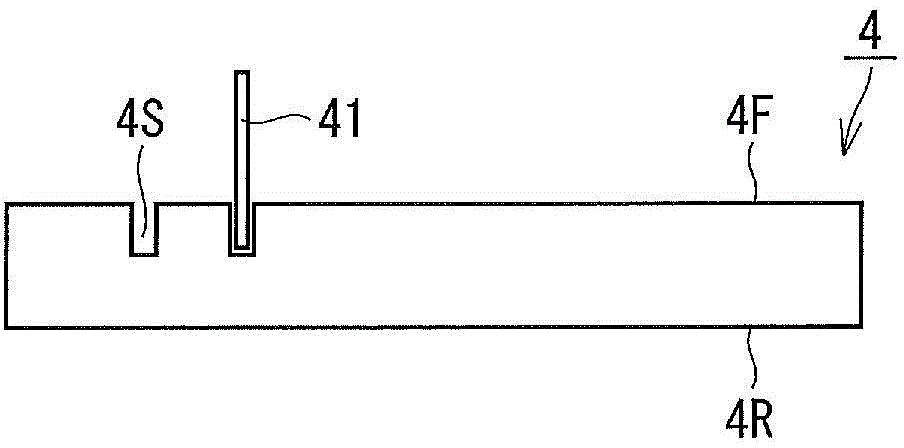

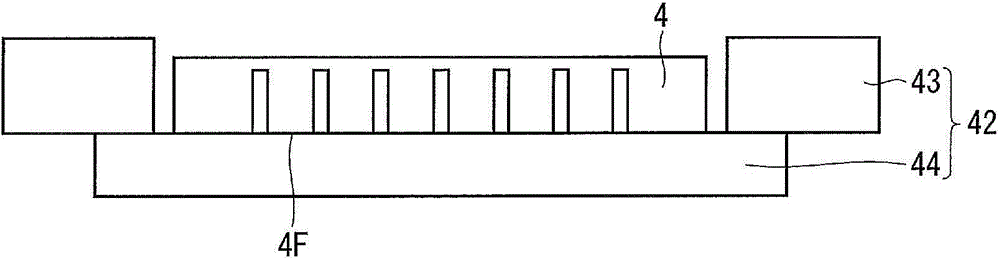

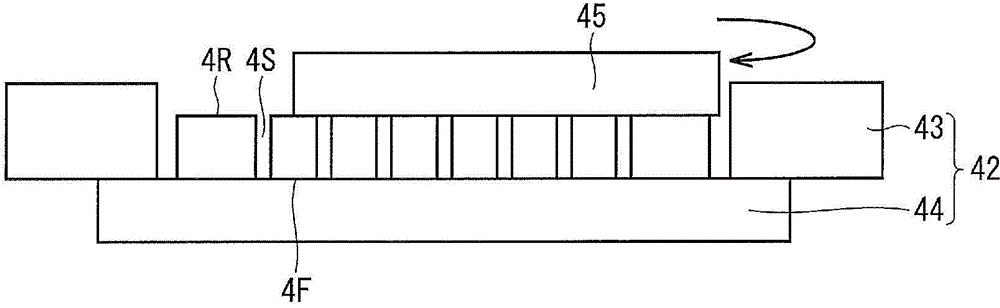

Semiconductor device manufacturing method, and adhesive film used in semiconductor device manufacturing method

ActiveCN104040697AInhibition of attachmentImprove cut-off reliabilityNon-macromolecular adhesive additivesSolid-state devicesEngineeringLength wave

The purpose of the present invention is to provide a semiconductor device manufacturing method, whereby cutting reliability of an adhesive film can be improved and debris contamination due to the adhesive film can be suppressed. Provided is a semiconductor device manufacturing method which is provided with: a step wherein, after forming a groove (4S) on the front surface of a semiconductor wafer (4), a protective adhesive film (44) is adhered, the rear surface of the semiconductor wafer is ground, and the groove is exposed from the rear surface; a step wherein, after adhering the adhesive film on the rear surface of the semiconductor wafer, the protective adhesive film is peeled; and a step wherein a laser beam having a wavelength of 355 nm is radiated along the groove exposed from the adhesive film, and the adhesive film is cut. The adhesive film has (a) a light absorption coefficient of 40 cm-1 or more at a wavelength of 355 nm, (b) a tensile storage elastic modulus of 0.5-20 MPa at 50 DEG C, and (c) a tensile storage elastic modulus of 0.3-7 MPa at 120 DEG C, or a melt viscosity of 2,000 Pa.s or more at 120 DEG C.

Owner:NITTO DENKO CORP

Peeling device and peeling method of substrate, and manufacturing method of electronic device

ActiveCN103972133AEliminates problems like strippingInhibition of ruptureLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:ASAHI GLASS CO LTD

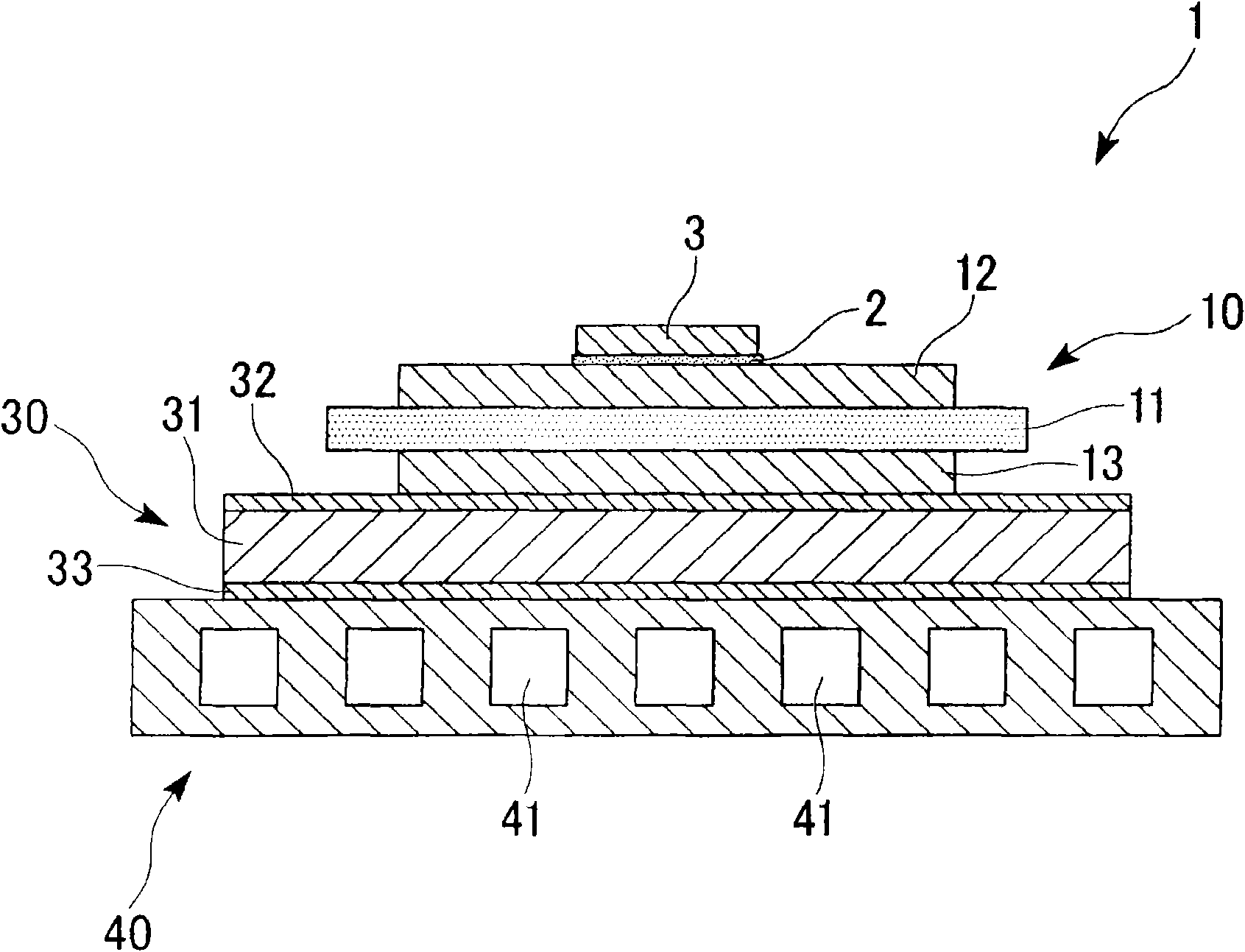

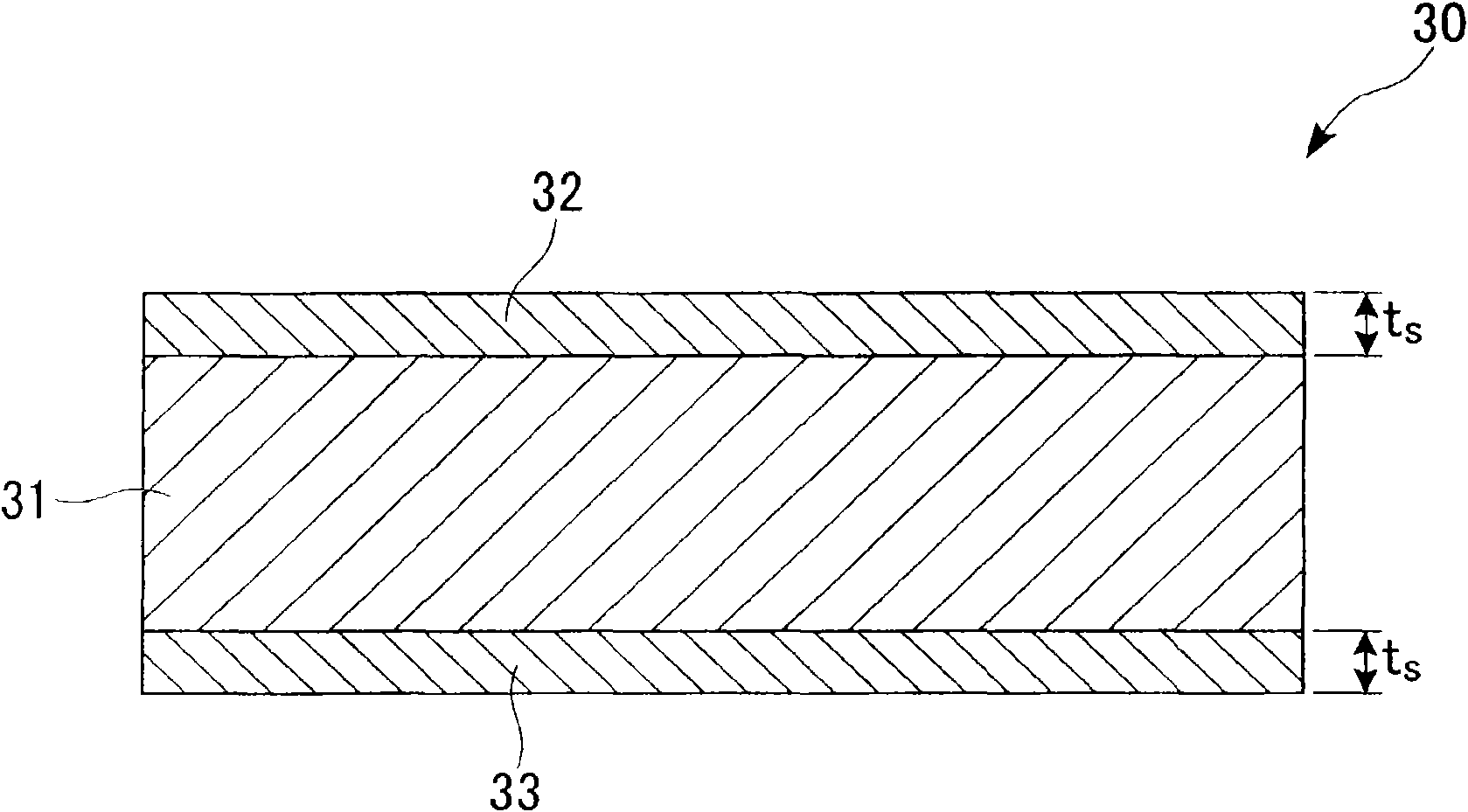

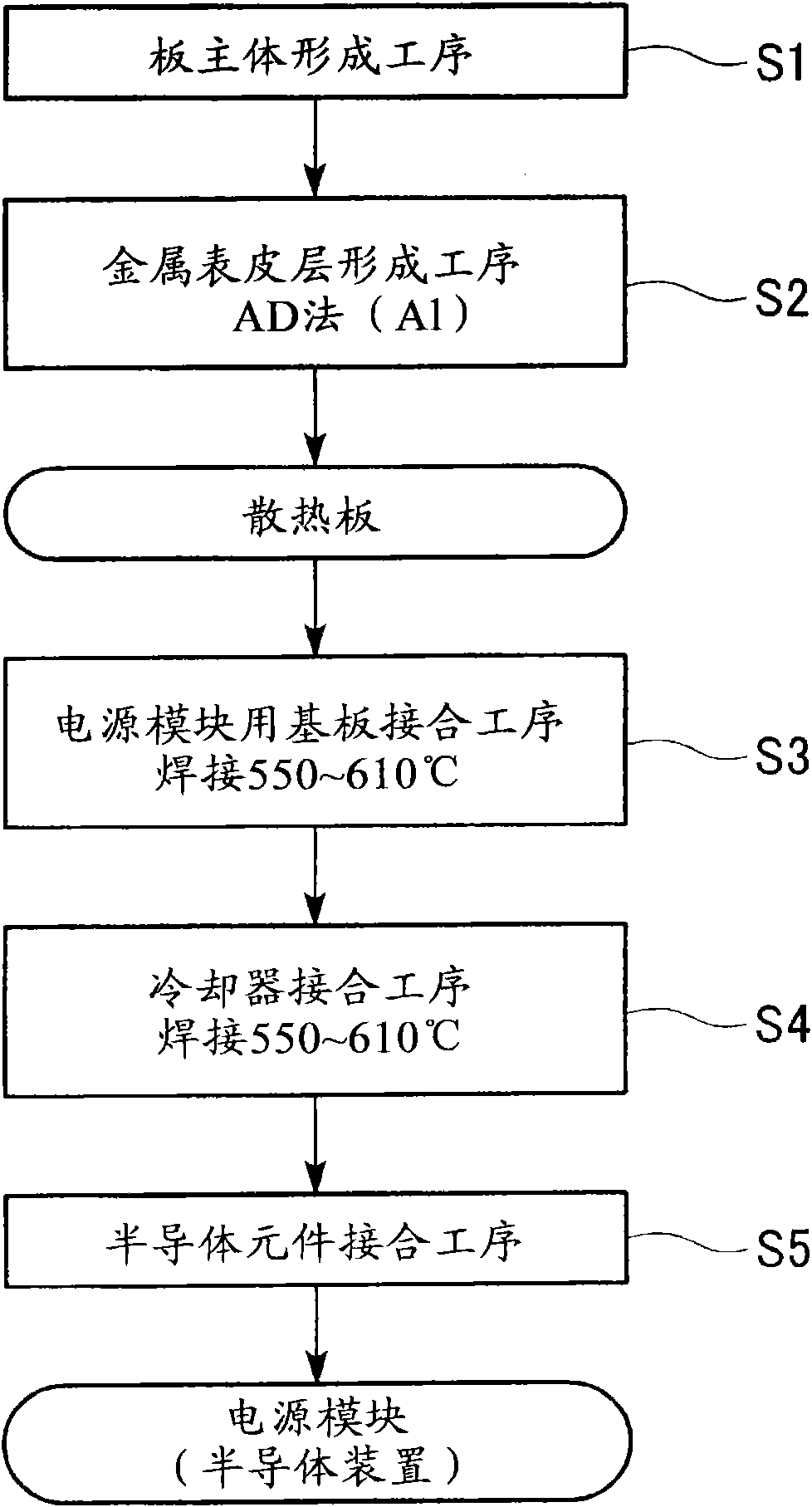

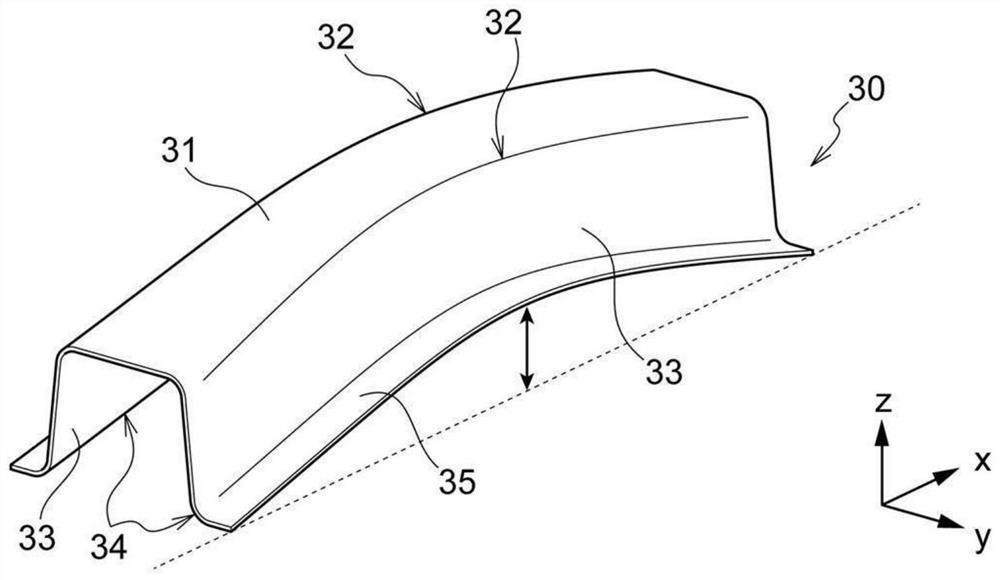

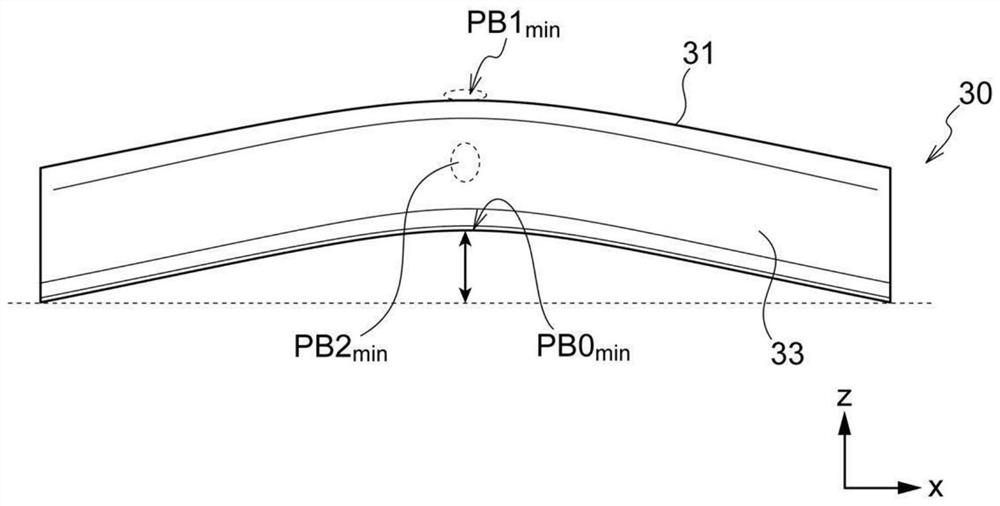

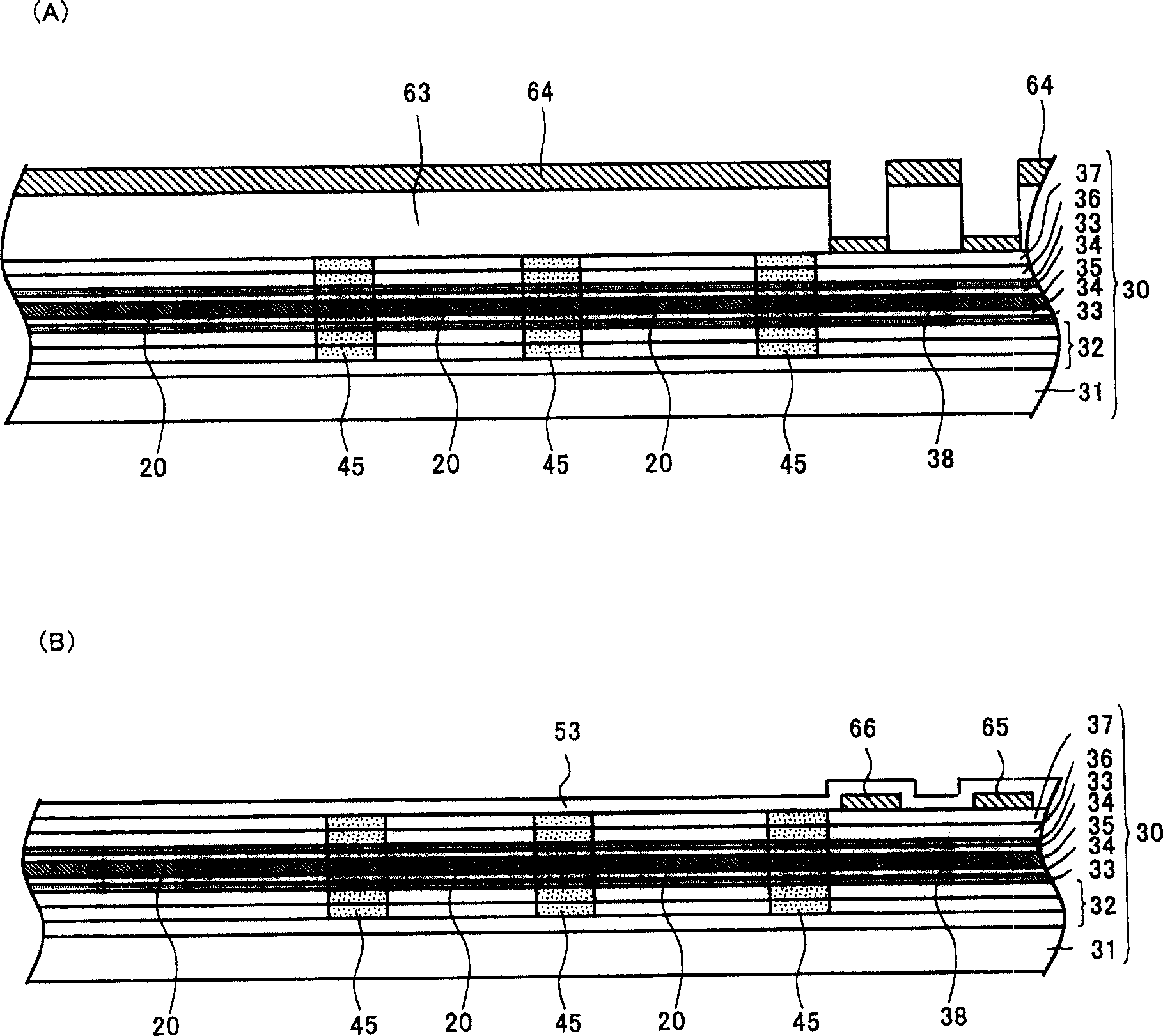

Heat radiation plate, semiconductor device and manufacturing method of heat radiation plate

InactiveCN102593080AInhibition Manufacturing MethodGood heat dissipationSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSurface layer

The invention provides a heat radiation plate which has an excellent heat radiation property and can prevent the heat stress from acting on heating bodies such as a semiconductor element under a cold and hot circulating load, a semiconductor device utilizing the heat radiation plate and a manufacturing method of the heat radiation plate. The heat radiation plate (30) is used for radiating heat produced by a heating body (3) which is carried by the heat radiation plate (30); and the heat radiation plate (30) is characterized by having a plate main body (31) and metal surface layers (32 and 33), wherein the plate main body (31) is formed by filling a metal-based composite material of a metal material into a carbon part, the metal surface layers (32 and 33) are formed on at least one side surface of the plate main body (31), the metal-based composite material forming the plate main body is formed by impregnating a molten metal material into the carbon part, and the metal surface layers (32 and 33) are formed through collision of metal powder onto the surfaces of the plate main body (31).

Owner:MITSUBISHI MATERIALS CORP

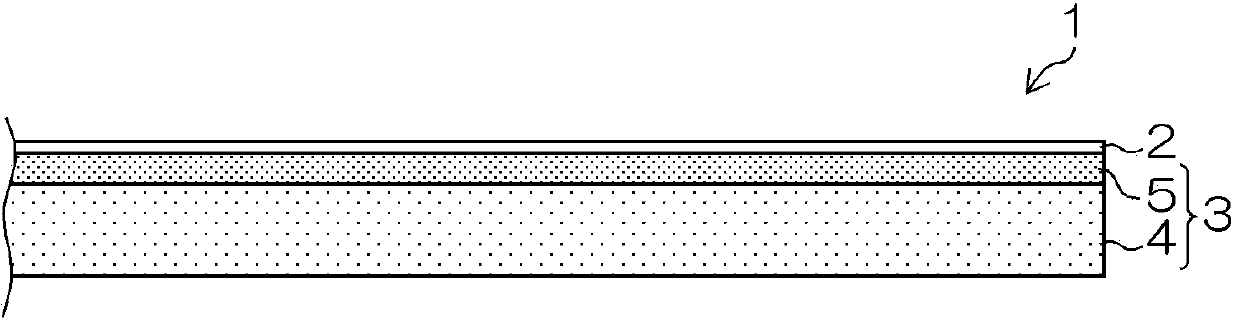

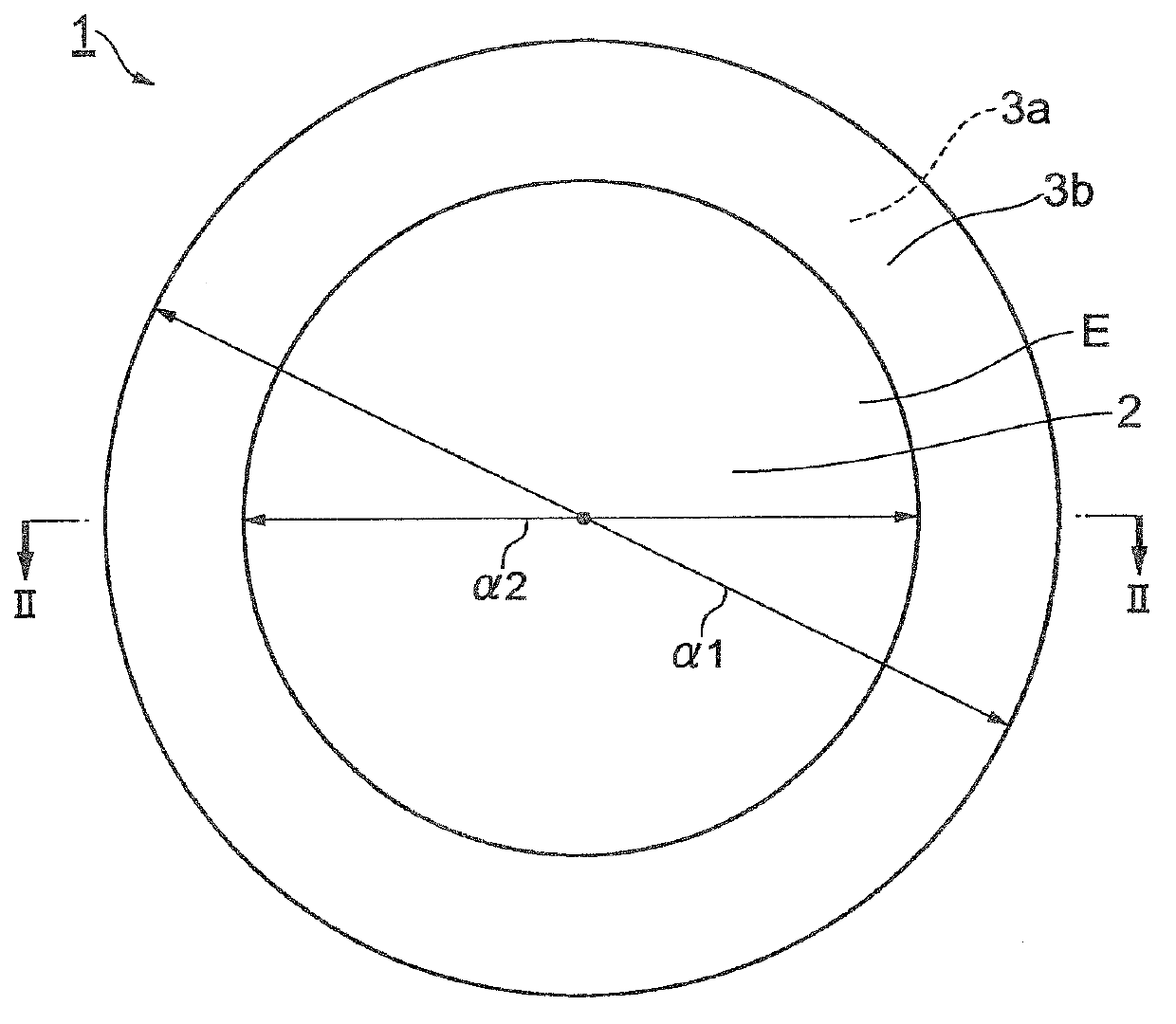

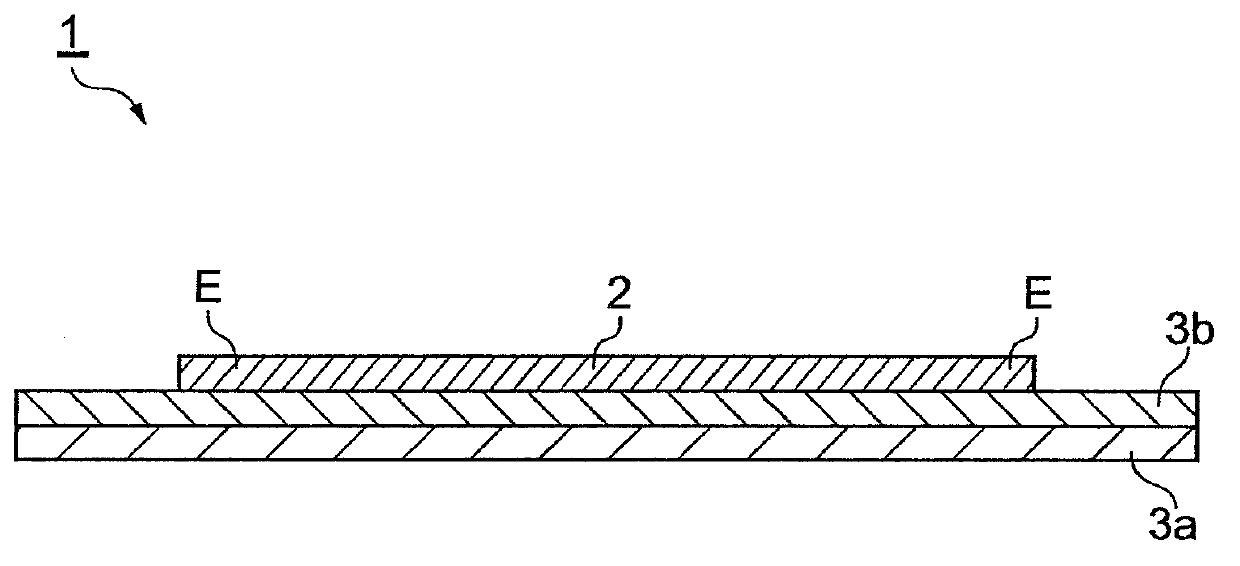

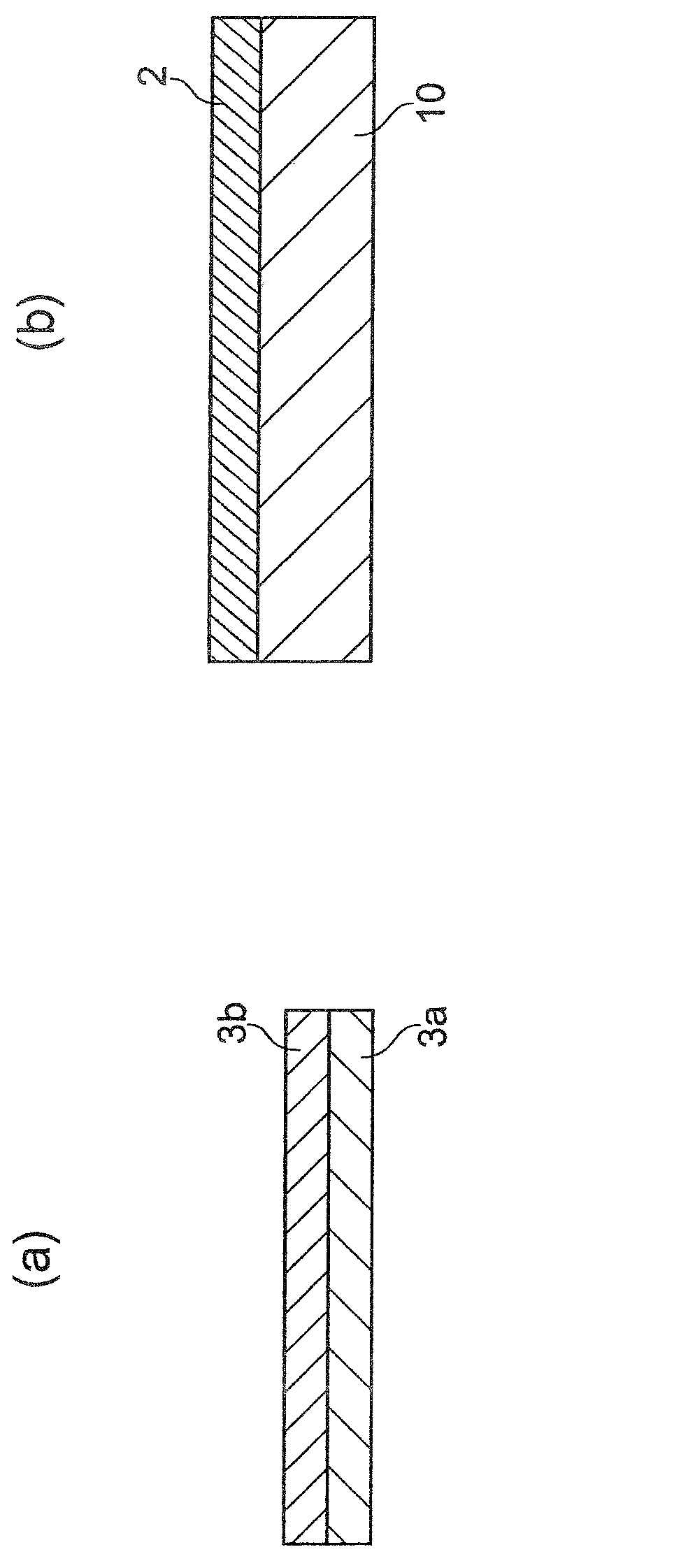

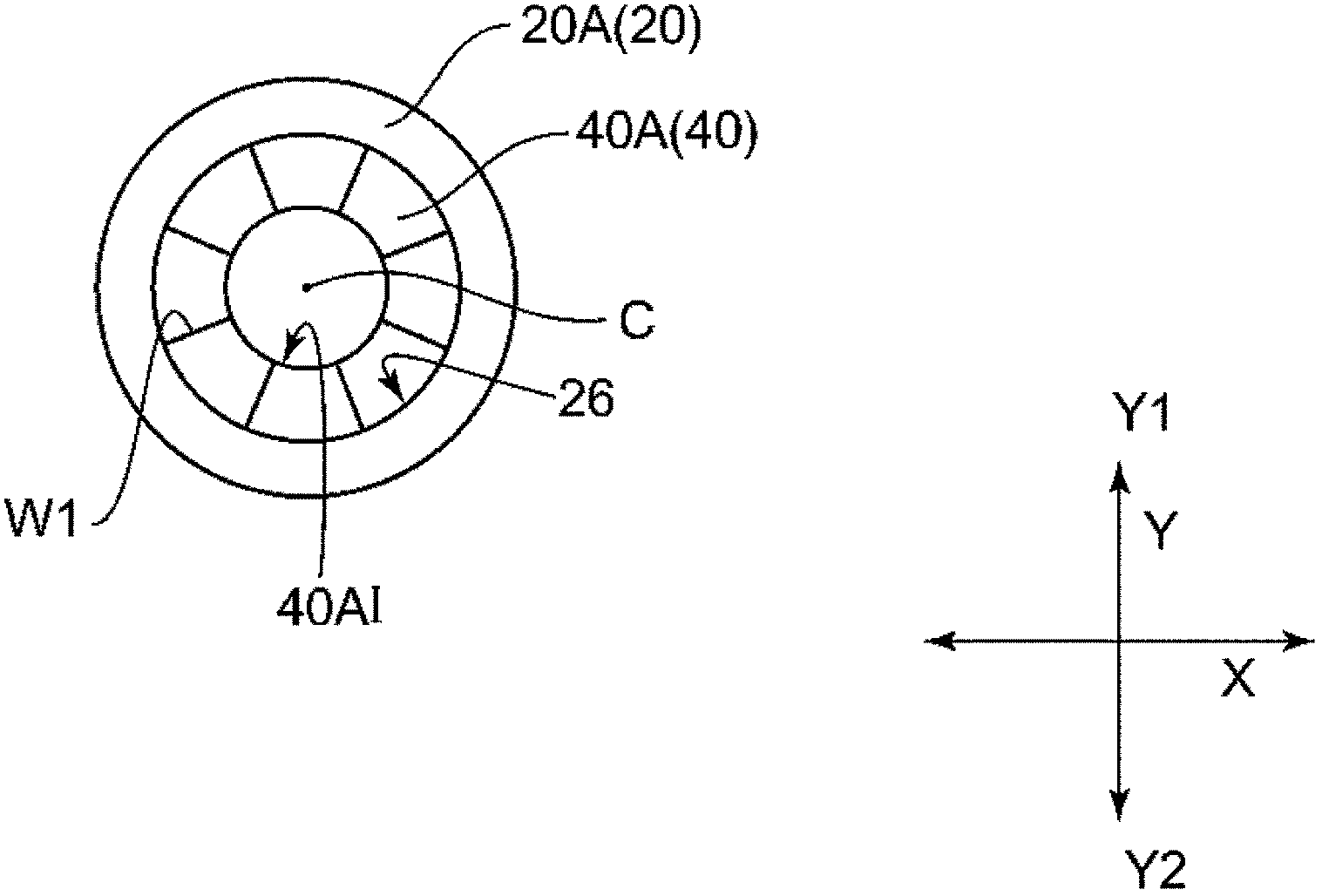

Dicing / die bonding integral film, dicing / die bonding integral film manufacturing method, and semiconductor chip manufacturing method

ActiveCN103109353AInhibition Manufacturing MethodFilm/foil adhesivesSolid-state devicesSemiconductor chipEngineering

The disclosed dicing / die bonding integral film manufacturing method prevents the edge (E) of an adhesive layer (2) from peeling off of a pressure-sensitive adhesive layer (3b) during the process of dicing a semiconductor wafer (W). The disclosed dicing / die bonding integral film is provided with a substrate film (3a), a pressure-sensitive adhesive layer formed on the substrate film and bonded to a wafer ring (R) used in blade dicing, and an adhesive layer formed on the pressure-sensitive adhesive layer and having a central part bonded to the semiconductor wafer which is to be blade-diced, wherein the planar shape of the adhesive layer is circular, and the surface area of the adhesive layer is greater than that of the semiconductor wafer and smaller than that of the substrate film and that of the pressure-sensitive adhesive film. The diameter of the adhesive layer is greater than that of the semiconductor wafer and smaller than the inner diameter of the wafer ring. The difference between the adhesive layer diameter and the semiconductor wafer diameter is greater than 20mm and less than 35mm.

Owner:RESONAC CORPORATION

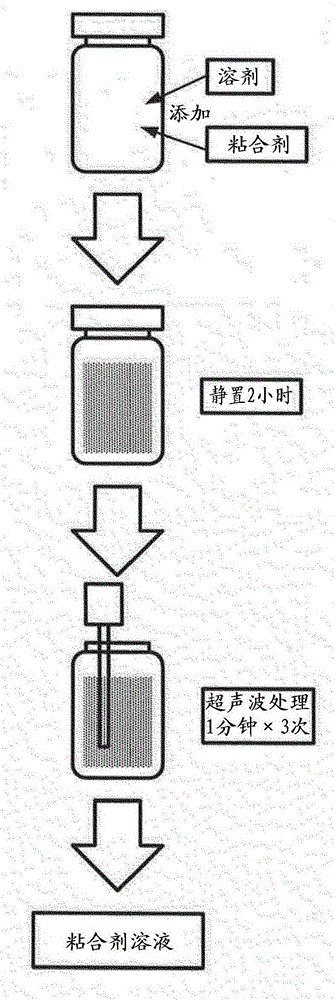

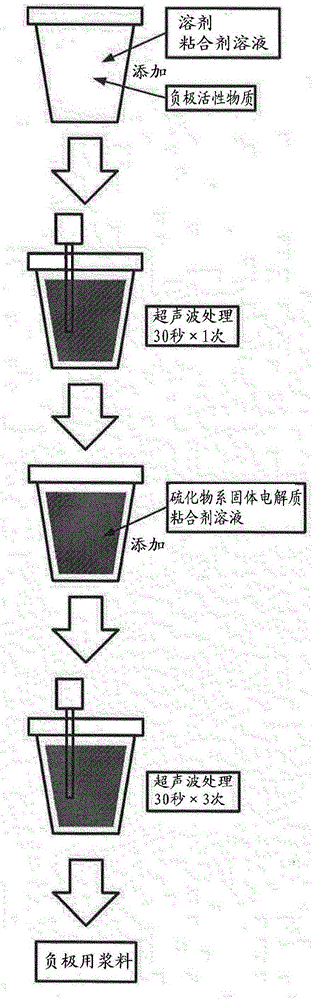

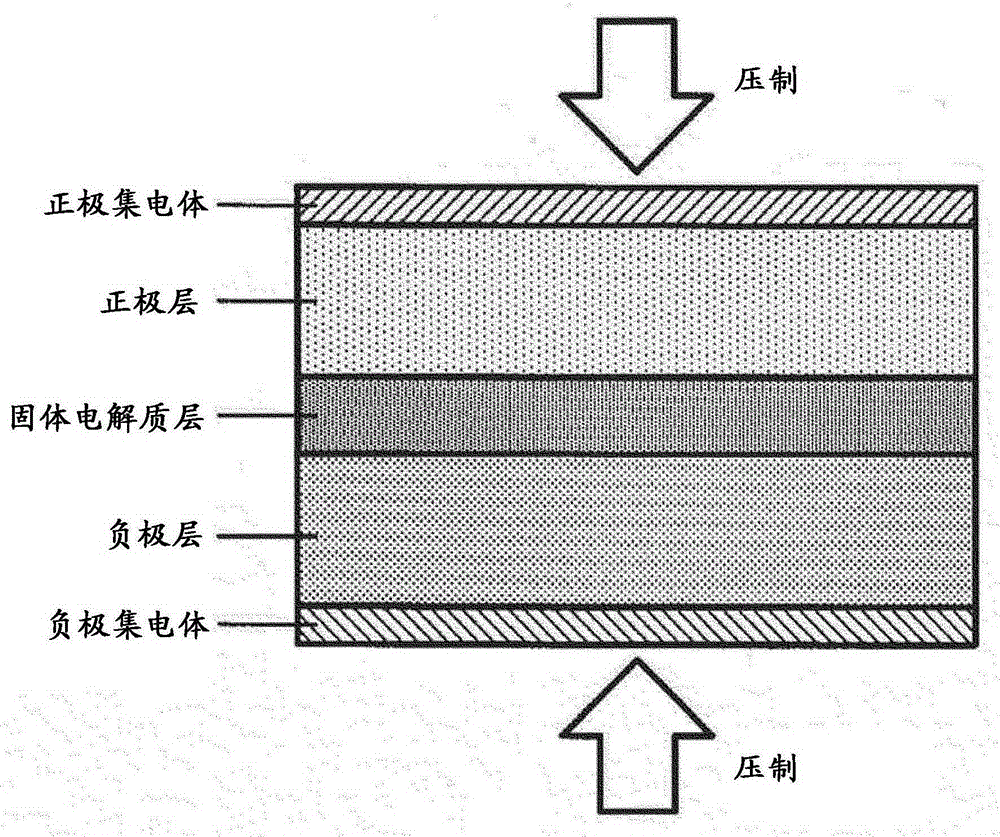

Method of manufacturing negative electrode for solid-state battery, method of manufacturing solid-state battery, and negative electrode slurry

ActiveCN105304904AInhibit deteriorationSuppress capacity deteriorationFinal product manufactureSecondary cellsSolid-state batterySolvent

The invention relates to a method of manufacturing a negative electrode for a solid-state battery, a method of manufacturing a solid-state battery, and negative electrode slurry. Provided is a method of manufacturing a negative electrode for a solid-state battery, the method including: a step of mixing a negative electrode active material, a sulfide solid electrolyte, a binder, and a solvent with each other to prepare a negative electrode slurry; a step of applying the prepared negative electrode slurry to a surface of a solid electrolyte layer of the solid-state battery or a substrate of the negative electrode; and a step of drying the applied negative electrode slurry. In this method, the solvent is butyl butyrate, and the binder is a copolymer containing a vinylidene fluoride (VDF) monomer unit and a hexafluoropropylene (HFP) monomer unit, in which a molar ratio of the HFP monomer unit to a total amount of the VDF monomer unit and the HFP monomer unit is 10% to 25%.

Owner:TOYOTA JIDOSHA KK

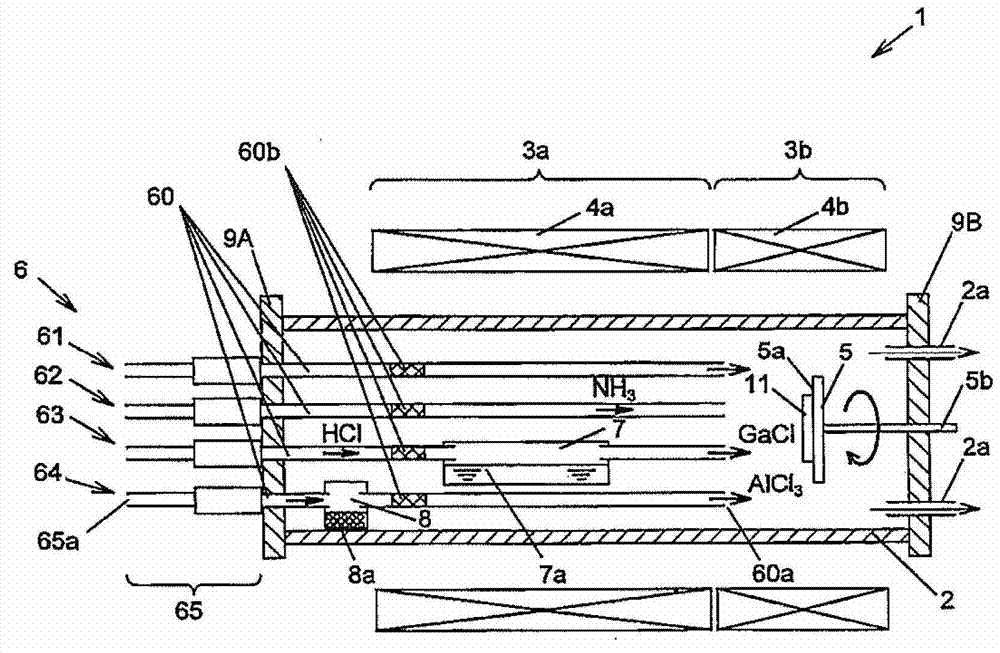

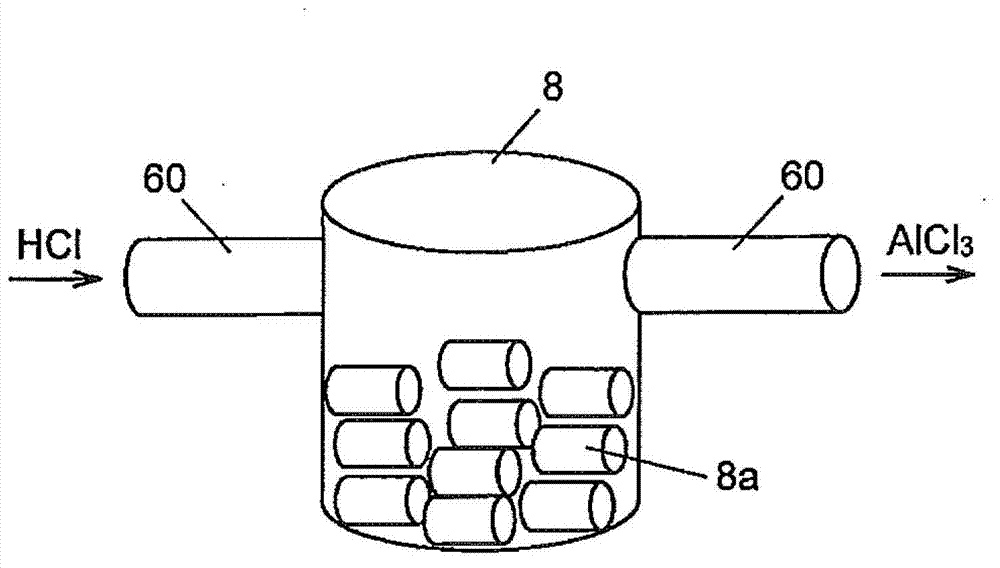

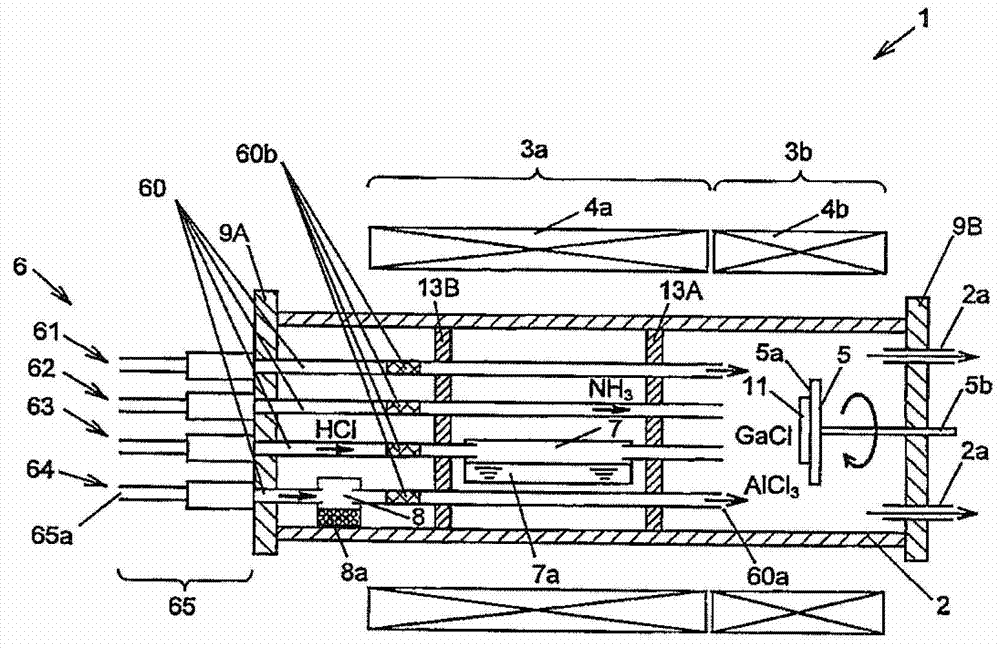

Metal chloride gas generator, hydride vapor phase epitaxy growth apparatus, and method for fabricating a nitride semiconductor template

InactiveCN103320763AInhibition Manufacturing MethodSuppression of optical waveguidingPolycrystalline material growthFrom chemically reactive gasesMetal chlorideRadiant heat

The invention provides a metal chloride gas generator, a hydride vapor phase epitaxy growth apparatus, and a nitride semiconductor template, wherein undesirable impurities are prevented from mixing with the raw materials of the nitride semiconductor template. An hydride vapor phase epitaxy (HVPE) growth apparatus comprises a Ga tank and an A1 tank both arranged at a raw material section on an upstream side, and a growing section reacting furnace provided with a growth sapphire substrate. A raw material section heater and a heater each of which heats an inside of the reactor, an upstream end comprising a gas inlet, and a gas inlet pipe arranged to extend from the upstream end via the receiving section to the growing section, for introducing a chloride gas from the upstream end to supply the chloride gas to the receiving section and supplying a metal chloride gas produced by a reaction between the chloride gas and the metal in the receiving section to the growing section. The gas inlet pipe includes a suppressing section for suppressing an optical wave guiding phenomenon which waveguides a radiant heat from the growing section heater or the growing section.

Owner:SUMITOMO CHEM CO LTD

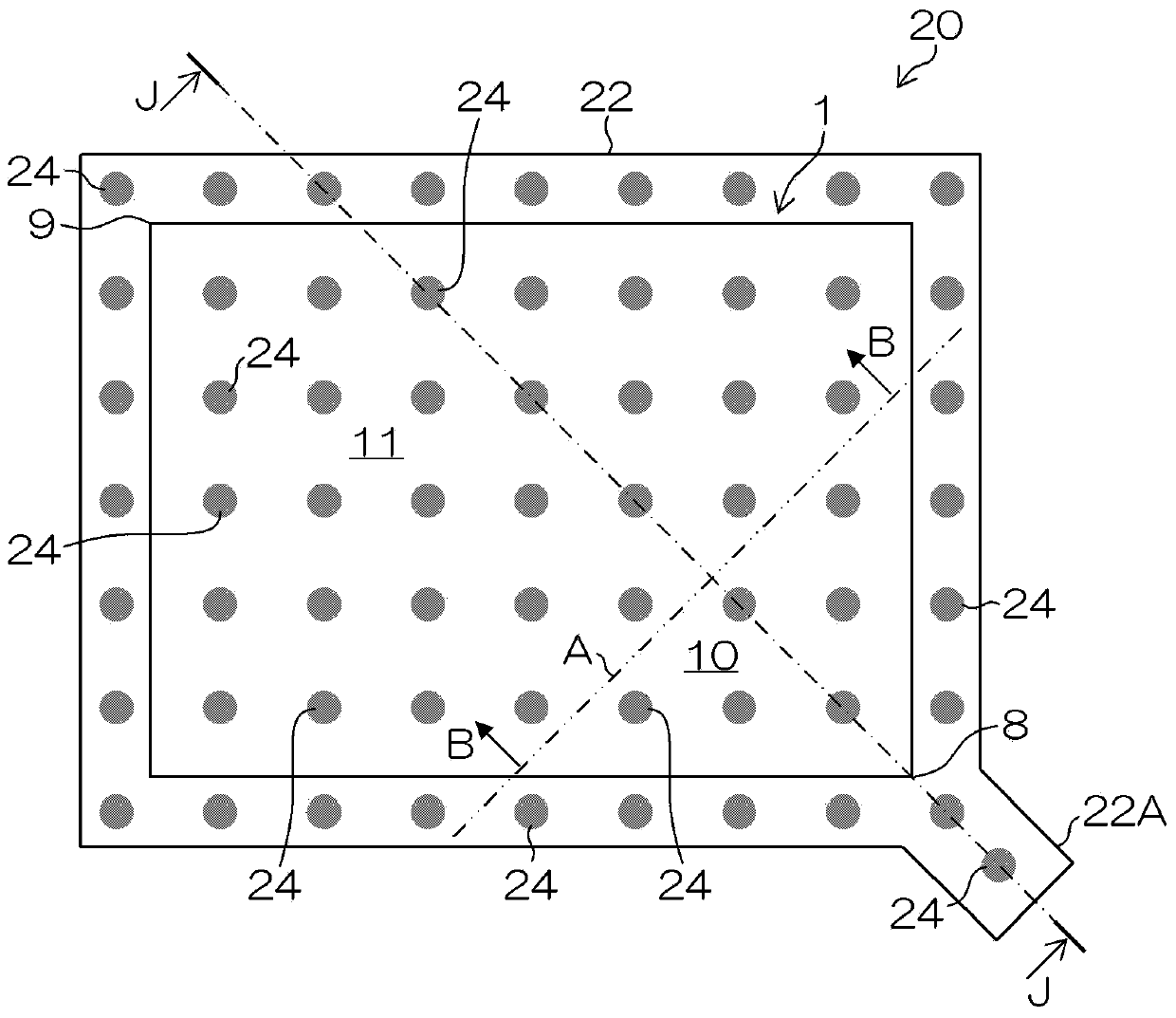

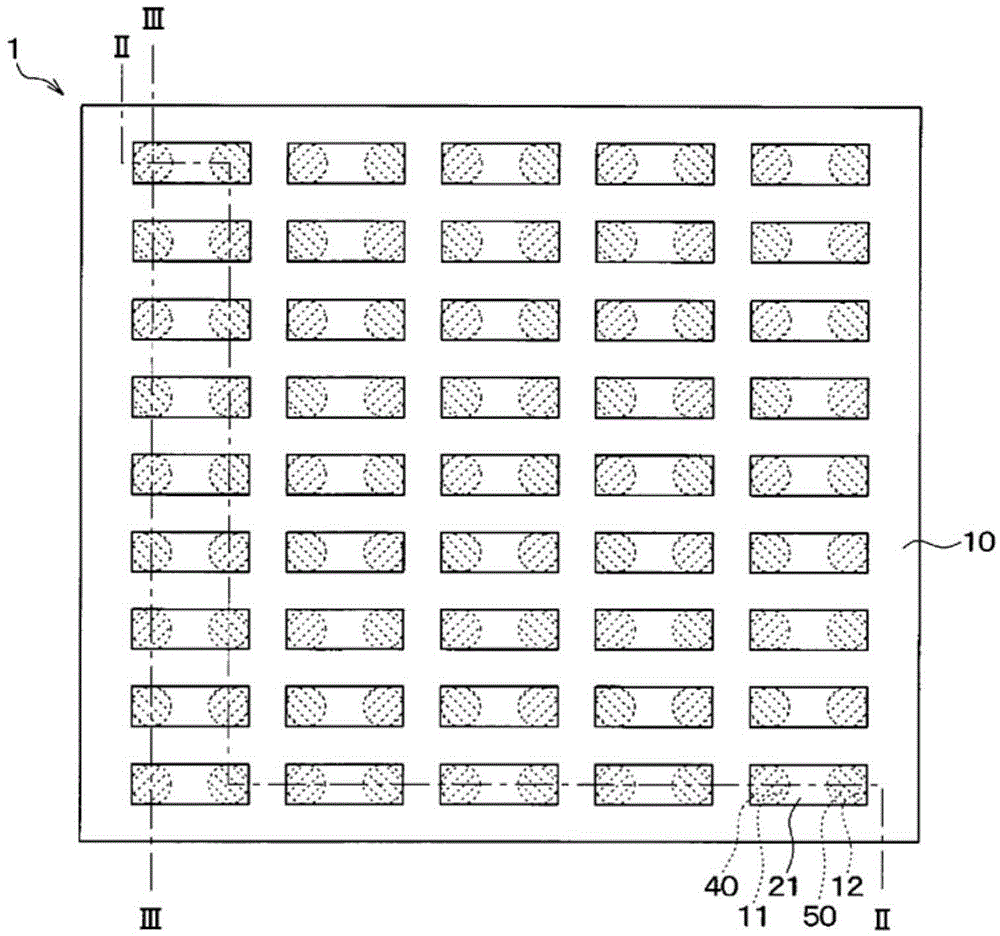

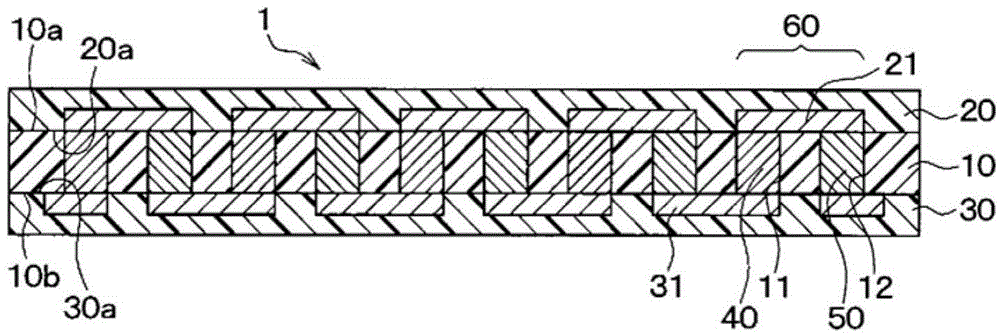

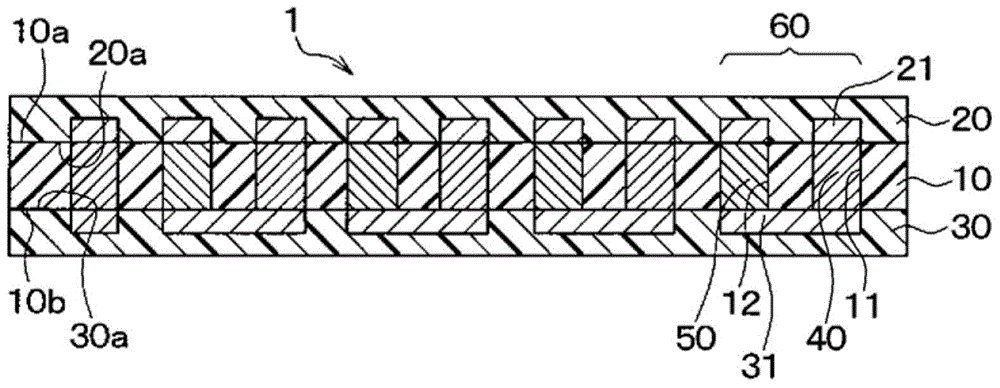

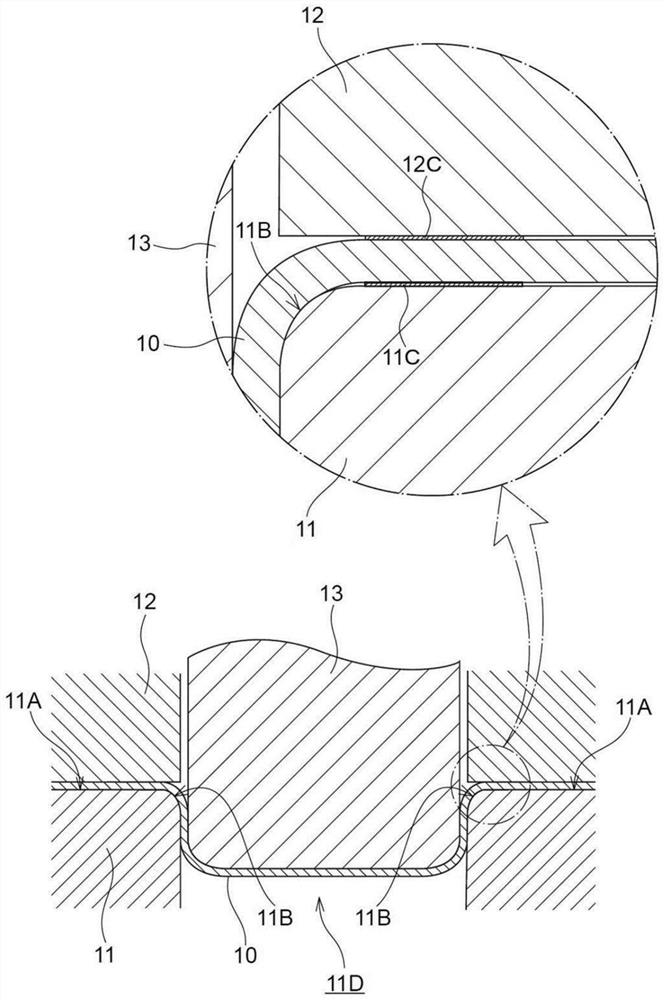

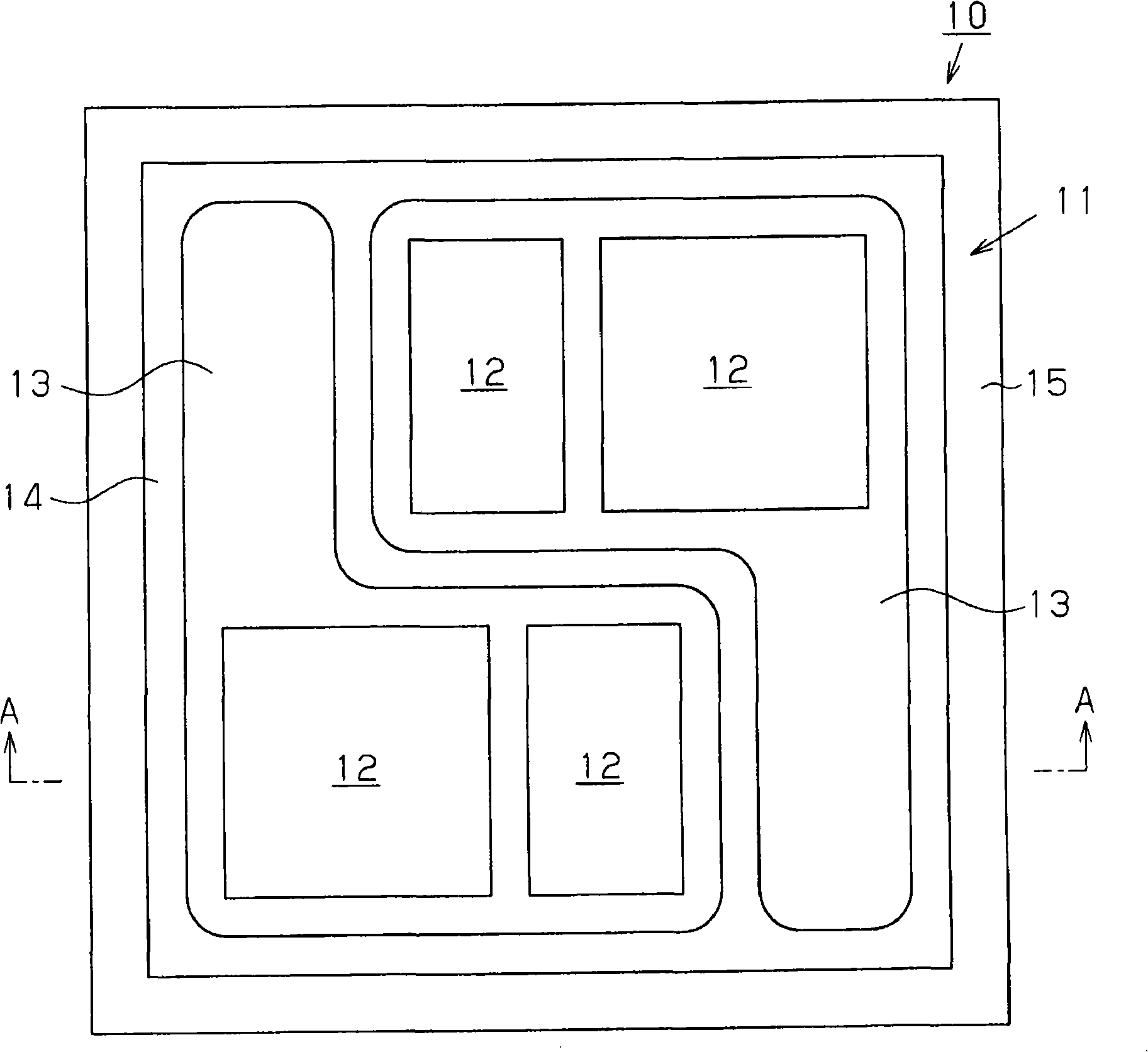

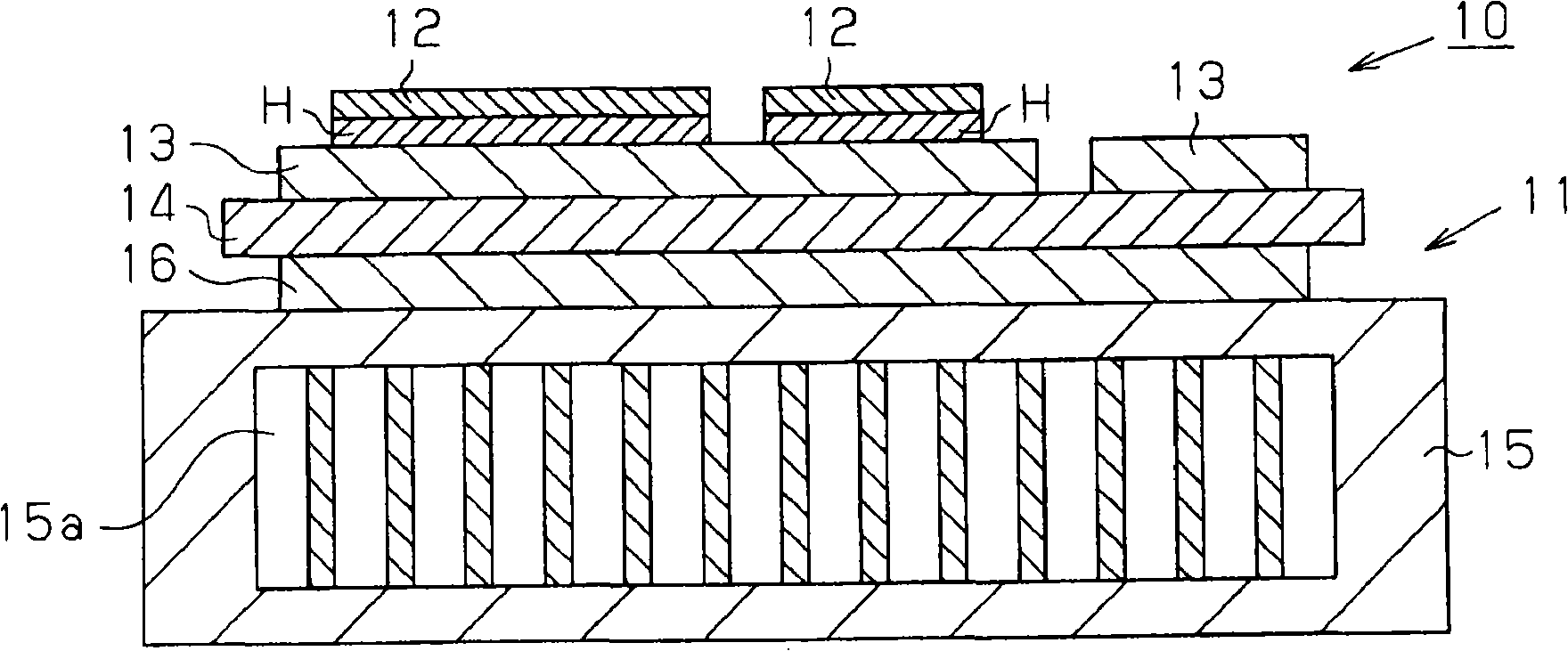

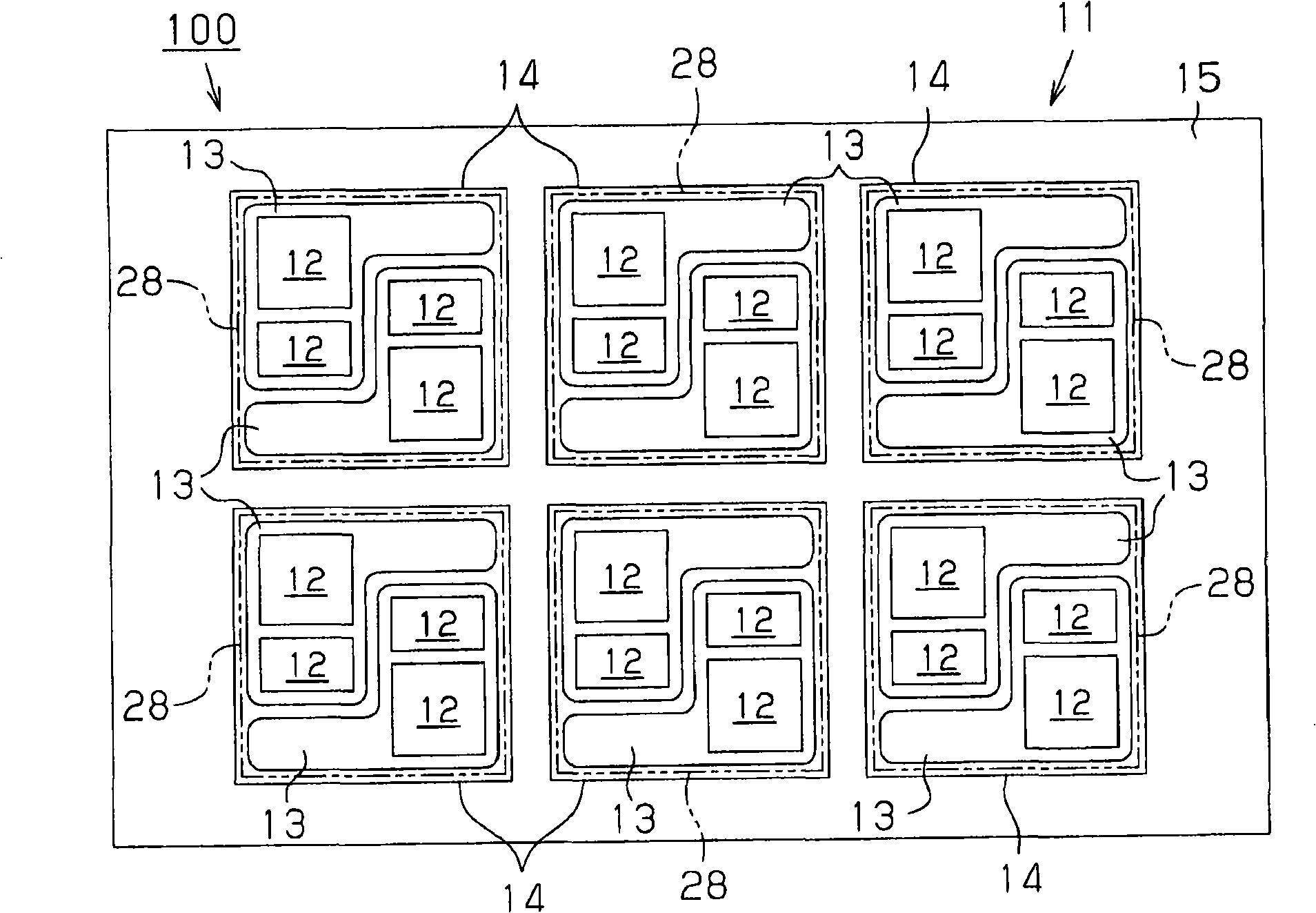

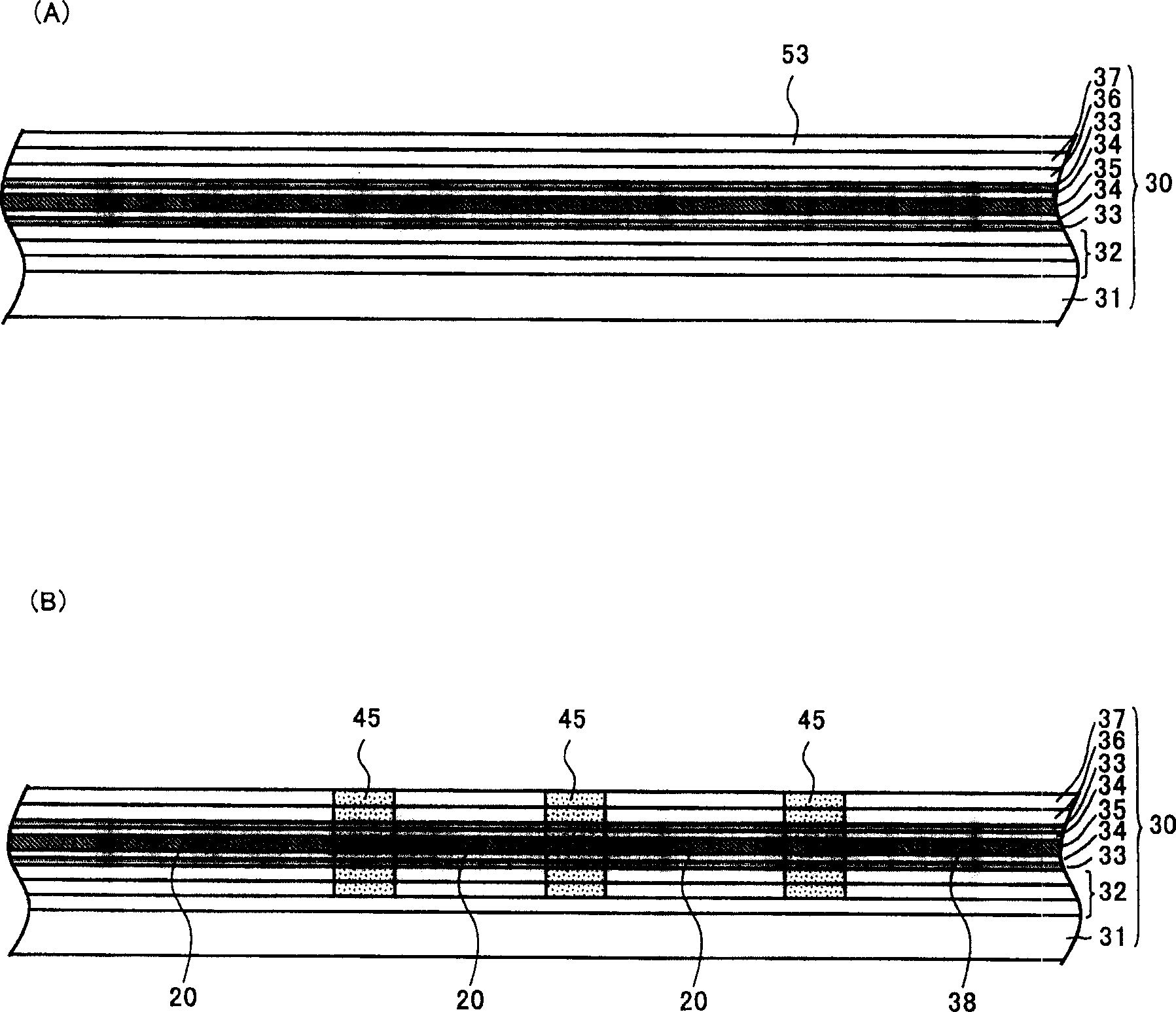

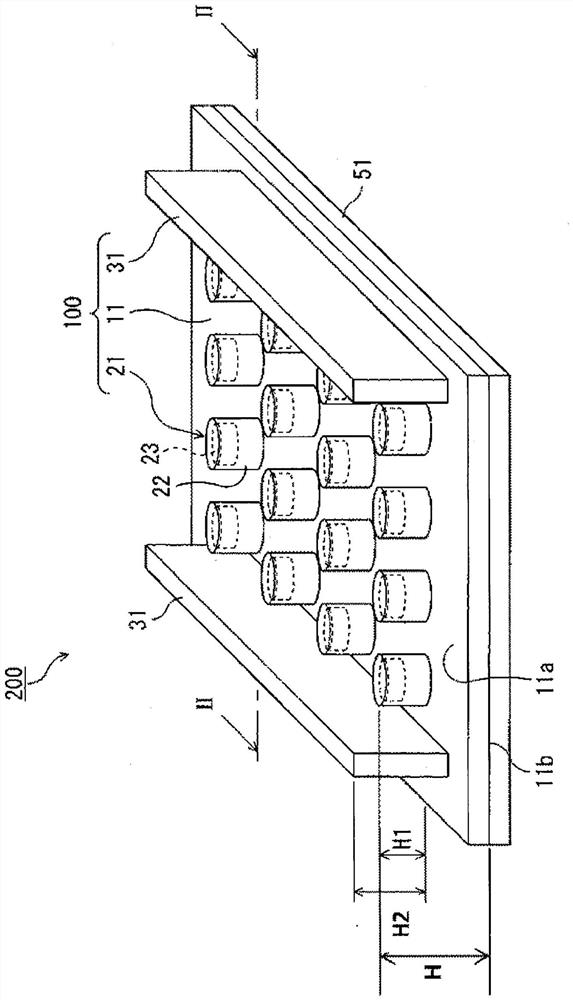

Method for manufacturing thermoelectric converter

ActiveCN104956506AInhibition Manufacturing MethodSimplify the manufacturing processThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentConductive pasteOrganic solvent

An insulating substrate (10) in which a plurality of via holes (11, 12) that penetrate said substrate in the thickness direction thereof are filled with a conductive paste (41, 51) is prepared. Said conductive paste (41, 51) is obtained by adding an organic solvent to an alloy powder in which a plurality of metal atoms maintain a prescribed crystal structure. Then, while the insulating substrate (10) is being heated, pressure is applied from the top surface (10a) and the bottom surface (10b) thereof. The conductive paste (41, 51) is thus subjected to solid-state sintering, forming interlayer connection members (40, 50). Next, a top-surface protection member (20) is placed on the top surface (10a) of the insulating substrate (10) and a bottom-surface protection member (30) is placed on the bottom surface (10b) of the insulating substrate (10), forming a laminate (80). Said laminate (80) is then fused into a single unit by the application of simultaneous heat and pressure, albeit at a lower temperature and with less pressure than were used in the step that formed the interlayer connection members (40, 50).

Owner:DENSO CORP +1

Production method for hot press molded articles, press molded article, die mold and mold set

ActiveCN111936248AInhibition Manufacturing MethodInhibit wearHot-dipping/immersion processesShaping toolsPolymer scienceZinc compounds

Owner:NIPPON STEEL CORP

Polyol composition for rigid polyurethane foam and process for producing rigid polyurethane foam

The invention provides a polyurethane rigid foam polyatomic alcohol compound which uses HFC-245fa as a foaming agent and simultaneously inhibits vapor pressure of the compound and a manufacturing method for polyurethane rigid foam. In the polyurethane rigid foam polyatomic alcohol compound, compositions of the foaming agents are 1,1,1,3,3-pentafluoropropane (HFC-245fa) and the foaming agents contain acetic acid diethylene glycol monoethylether ester. The polyatomic alcohol compound of the invention comprises a polyatomic alcohol compound provided with tertiary amino groups, and weight percent of nitrogen based on the amino groups is 0.5 to 9 percent of the polyatomic alcohol compound. HFC-365mfc or HFE-254pc is preferably selected as composition of the foaming agent.

Owner:SEKISUI SOFLAN WIZ CO LTD

Soldering method and semiconductor module manufacturing method

InactiveCN101351874AInhibition Manufacturing MethodPrinted circuit assemblingFinal product manufactureComputer moduleEngineering

Disclosed is a method for soldering semiconductor elements on bonding sections arranged at a plurality of areas on a circuit board, respectively. The soldering method is provided with a step of arranging the bonding sections in nonlinear arrangement on at least three areas on the circuit board; a step of arranging the semiconductor elements on the bonding sections through a solder; a step of placing a guard over the at least three semiconductor elements nonlinearly arranged; and a step of melting the solder while applying pressure to the semiconductor elements by the guard, and thus soldering the semiconductor elements on the bonding sections. As a result, at the time of soldering the semiconductor elements on the circuit board, fluctuation in solder thickness at the bonding sections is suppressed.

Owner:TOYOTA IND CORP

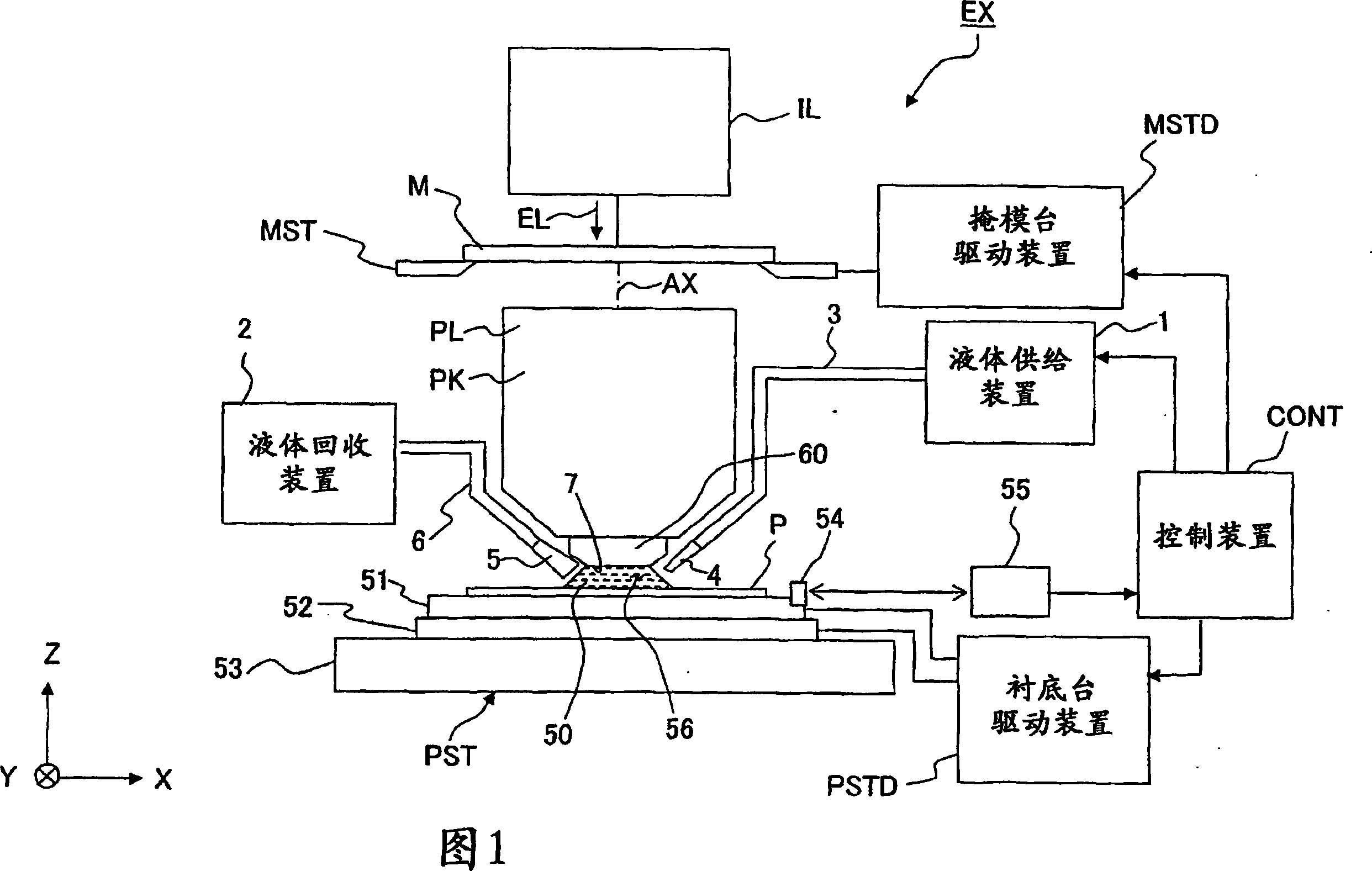

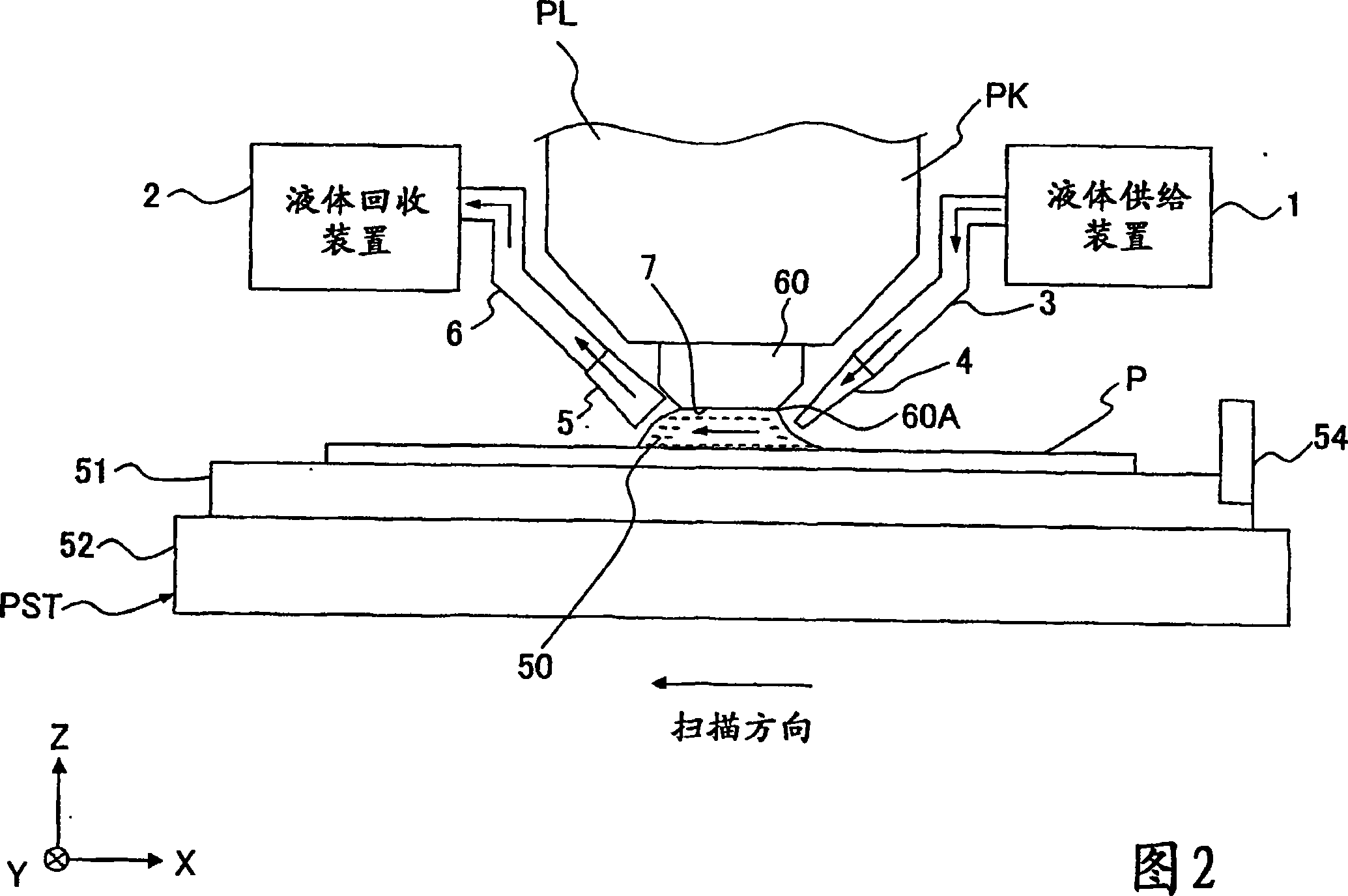

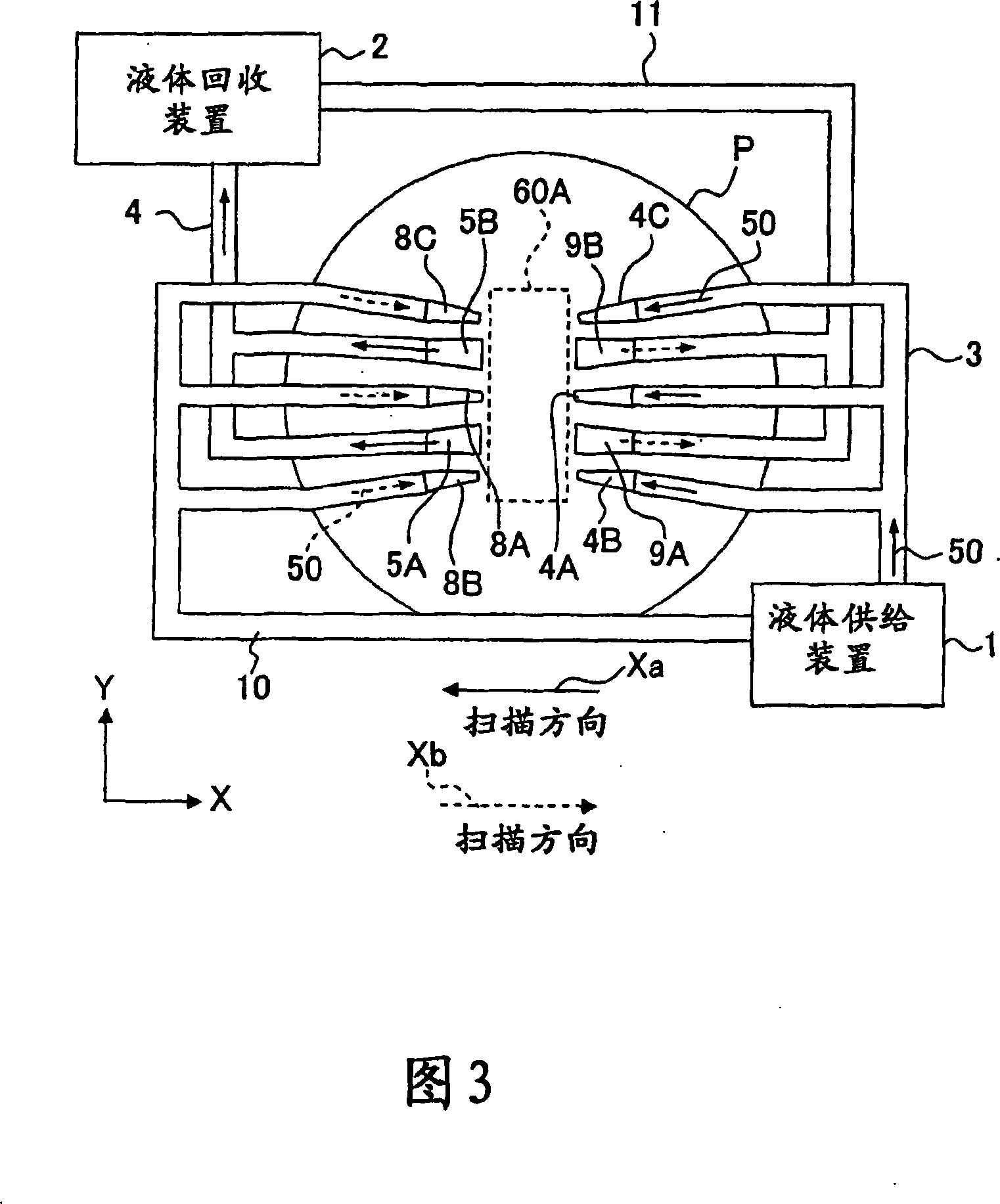

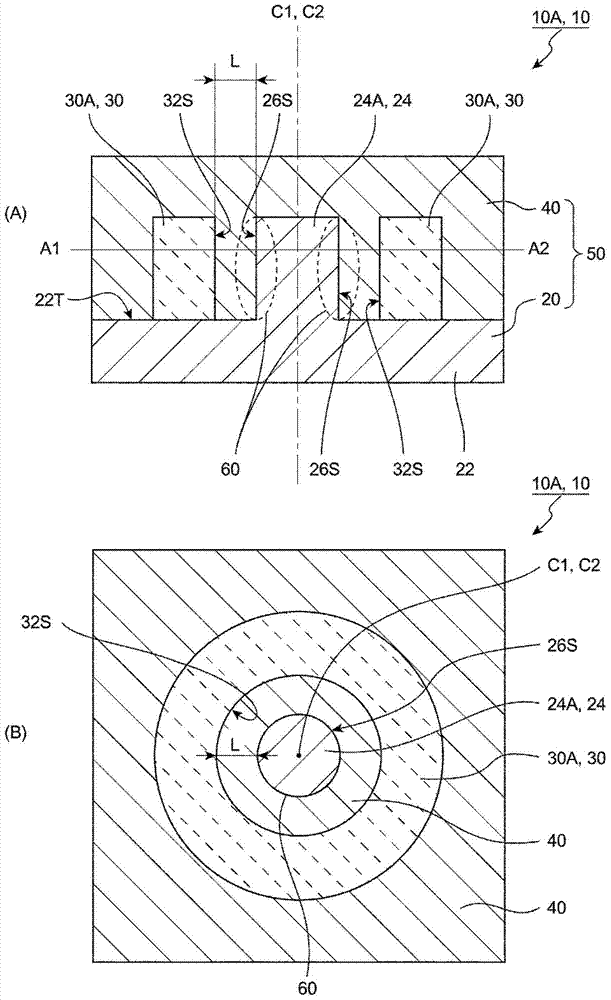

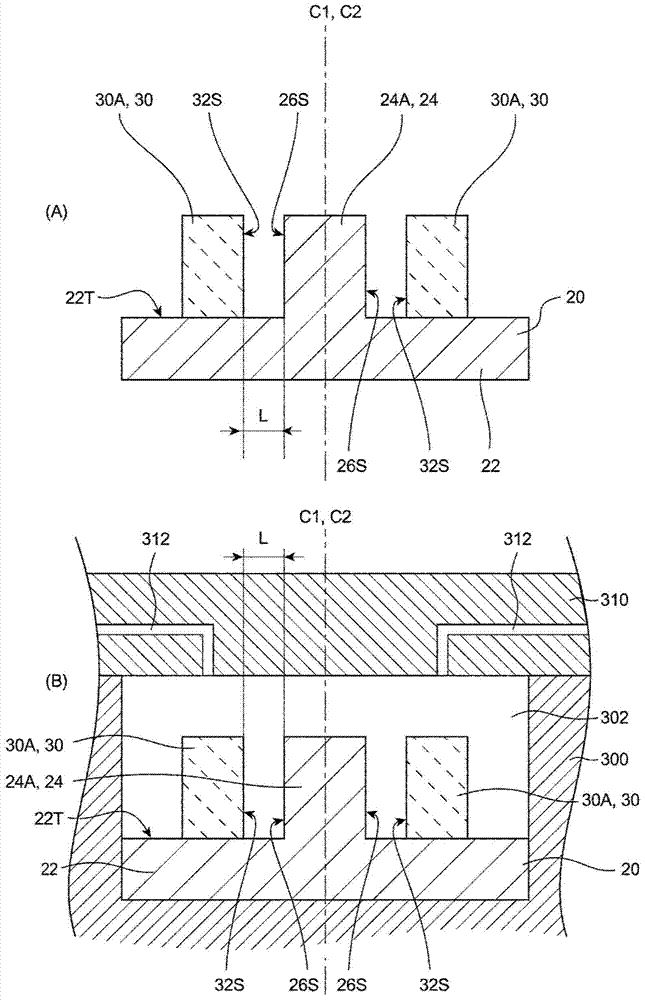

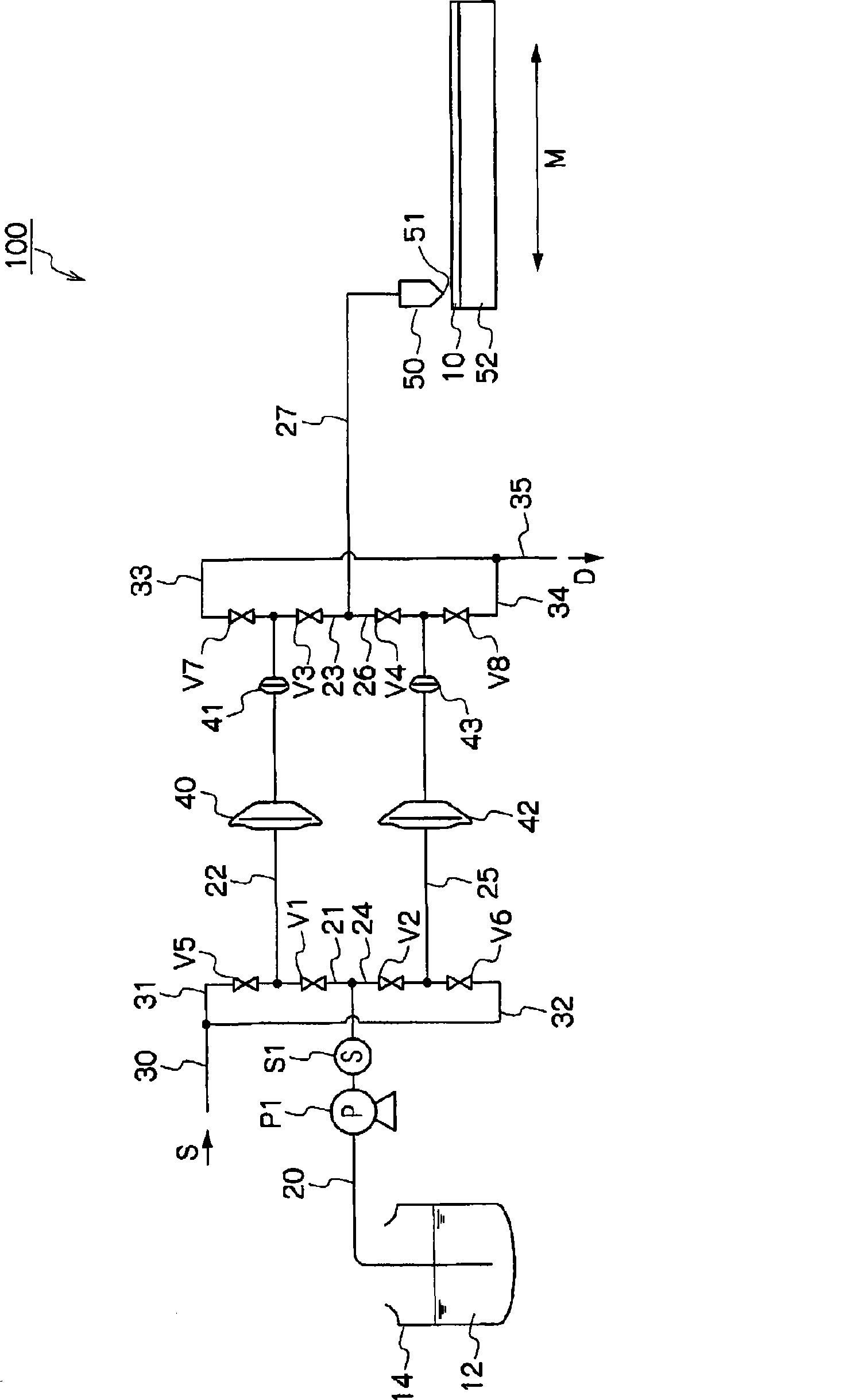

Method for producing device

InactiveCN101101455AInhibition Manufacturing MethodSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamEngineering

An exposure apparatus, wherein exposure is carried out while filling a space between a projection optical system and a substrate with a liquid, enables to suppress deterioration of a pattern image caused by any bubble in the liquid. The exposure apparatus includes a liquid supply unit 1 which fills at least a part of the space between the projection optical system and the substrate with a liquid 50 , and exposes the substrate by projecting an image of a pattern onto the substrate via the projection optical system. The liquid supply unit 1 includes a degassing unit 21 which suppresses the generation of the bubble in the liquid 50.

Owner:NIKON CORP

Polyol composition for rigid polyurethane foam and process for producing rigid polyurethane foam

The invention provides a polyurethane rigid foam polyatomic alcohol compound which uses HFC-245fa as a foaming agent and simultaneously inhibits vapor pressure of the compound and a manufacturing method for polyurethane rigid foam. In the polyurethane rigid foam polyatomic alcohol compound, compositions of the foaming agents are 1,1,1,3,3-pentafluoropropane (HFC-245fa) and the foaming agents contain acetic acid diethylene glycol monoethylether ester. The polyatomic alcohol compound of the invention comprises a polyatomic alcohol compound provided with tertiary amino groups, and weight percent of nitrogen based on the amino groups is 0.5 to 9 percent of the polyatomic alcohol compound. HFC-365mfc or HFE-254pc is preferably selected as composition of the foaming agent.

Owner:SEKISUI SOFLAN WIZ CO LTD

Method of manufacturing magnetic element and magnetic element

ActiveCN103489622AInhibition Manufacturing MethodTransformers/inductances magnetic coresCoils manufactureInjection molding machineMechanical engineering

The magnetic element has a first core member, a winding part, and a second core member, and is manufactured by way of at least a winding part placement step of placing the winding part on the face of the first core member on the side on which the core part is provided, such that the core part is positioned within the inner periphery of the winding part, and an injection molding step of injection molding so as to surround the first core member and the winding part with resin material, and in the winding part placement step, the winding part is placed on the face of the first core member on the side on which the core part is provided, with at least a portion of the inner peripheral face of the winding part distanced from the outer peripheral face of the core part.

Owner:SUMIDA CORP

Compound semiconductor device and manufacturing method thereof

InactiveCN1747182AAvoid defectsImprove yieldTransistorSemiconductor/solid-state device detailsHigh concentrationOptoelectronics

Owner:SANYO ELECTRIC CO LTD

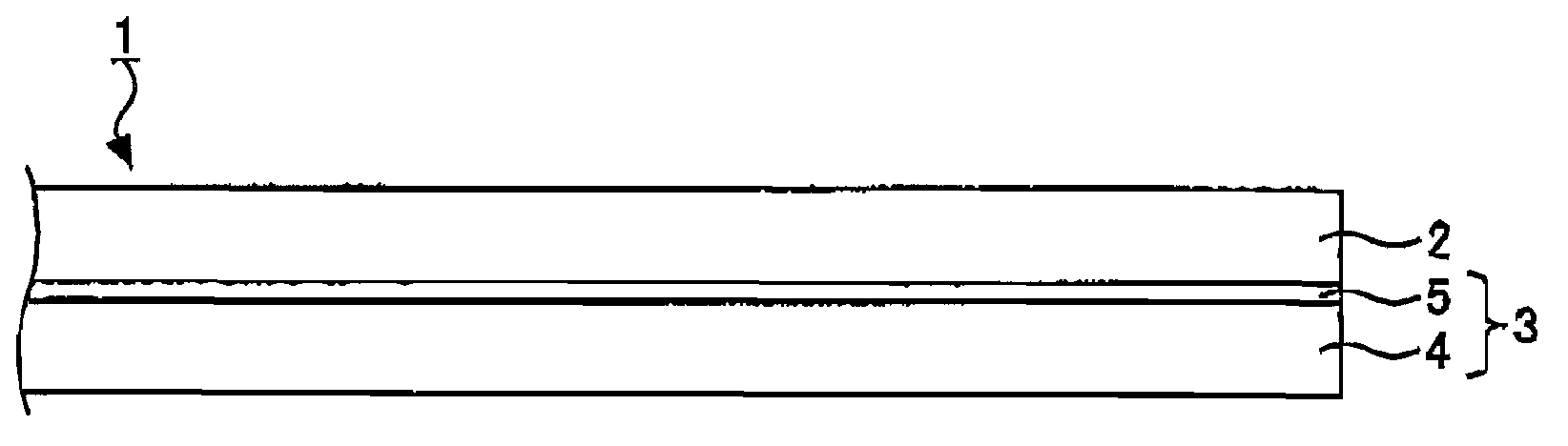

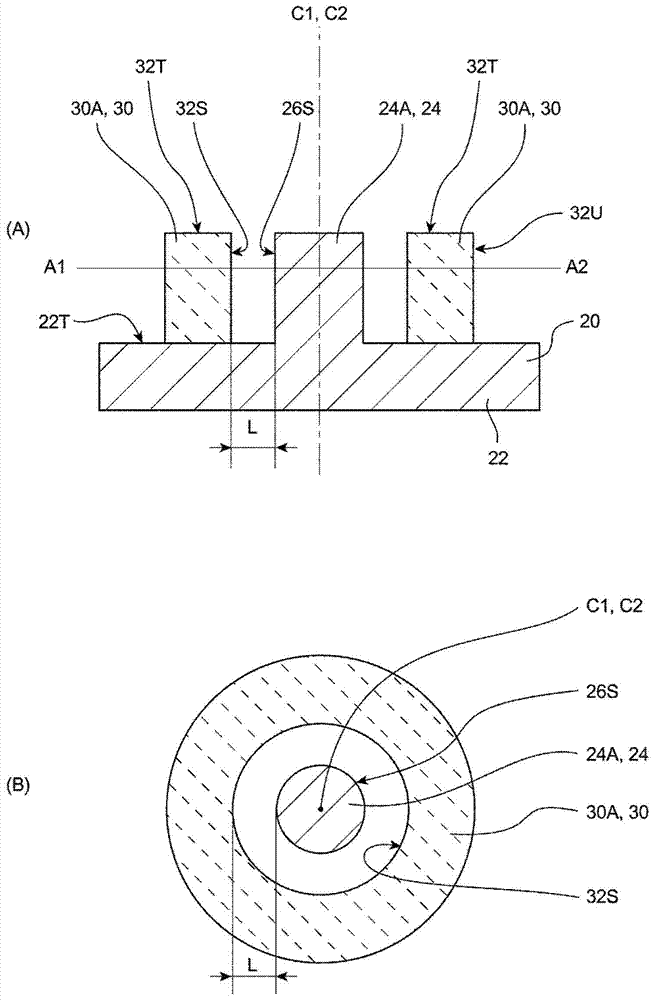

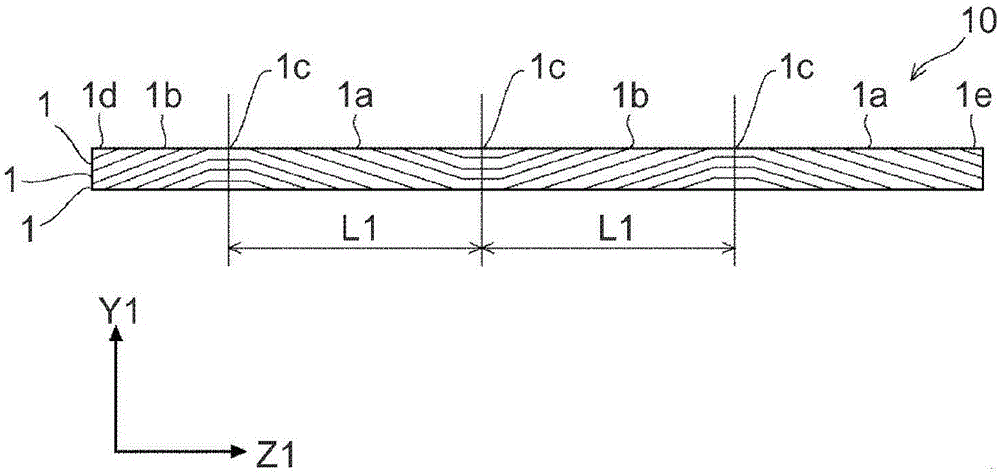

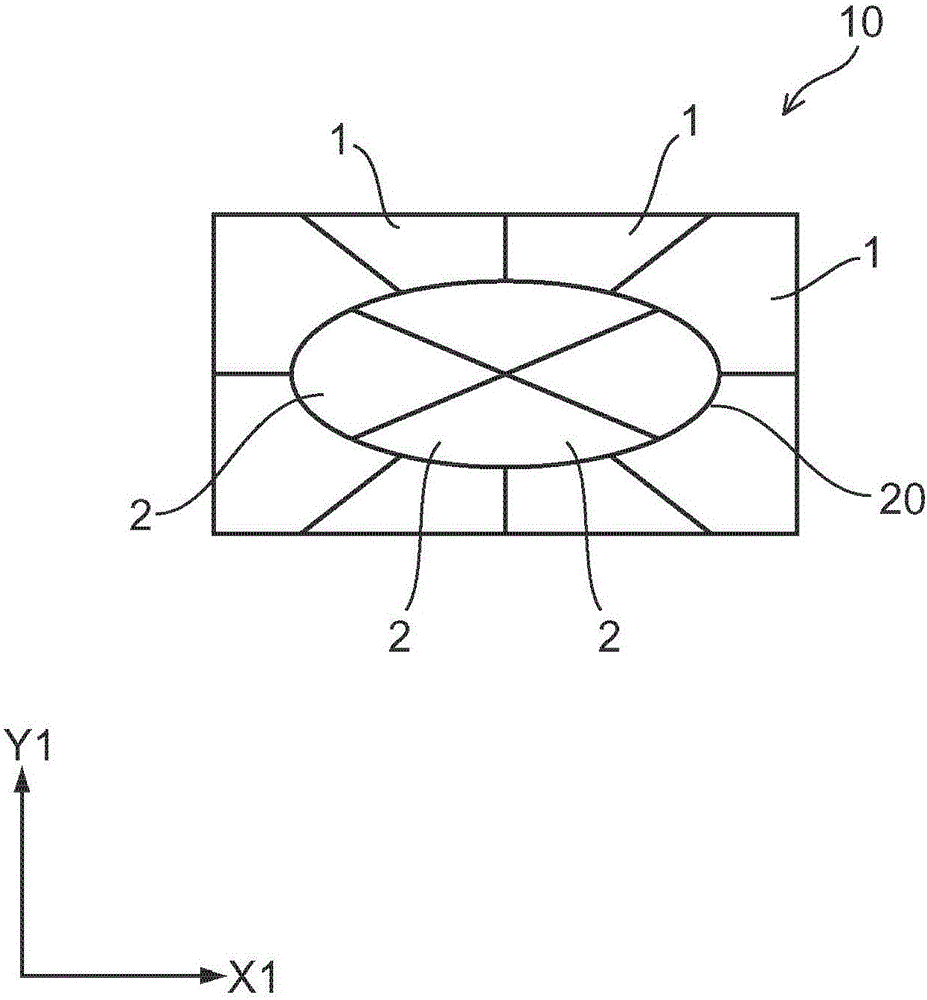

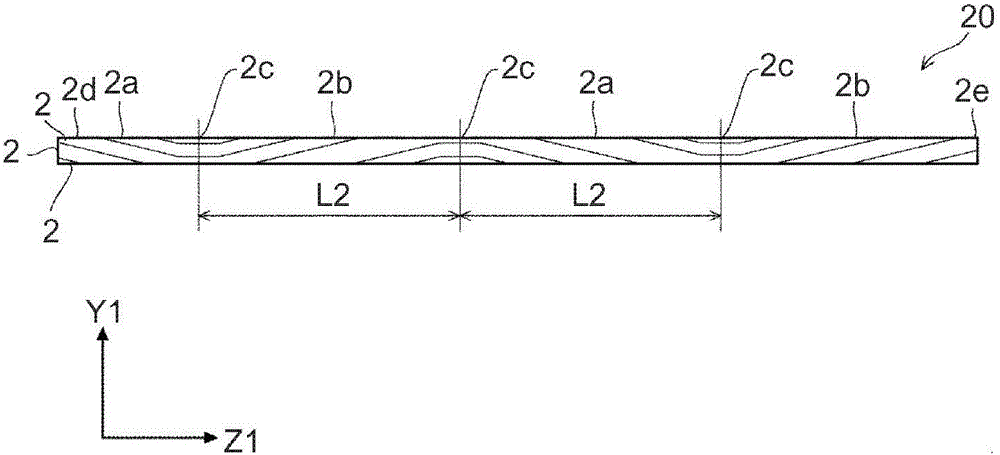

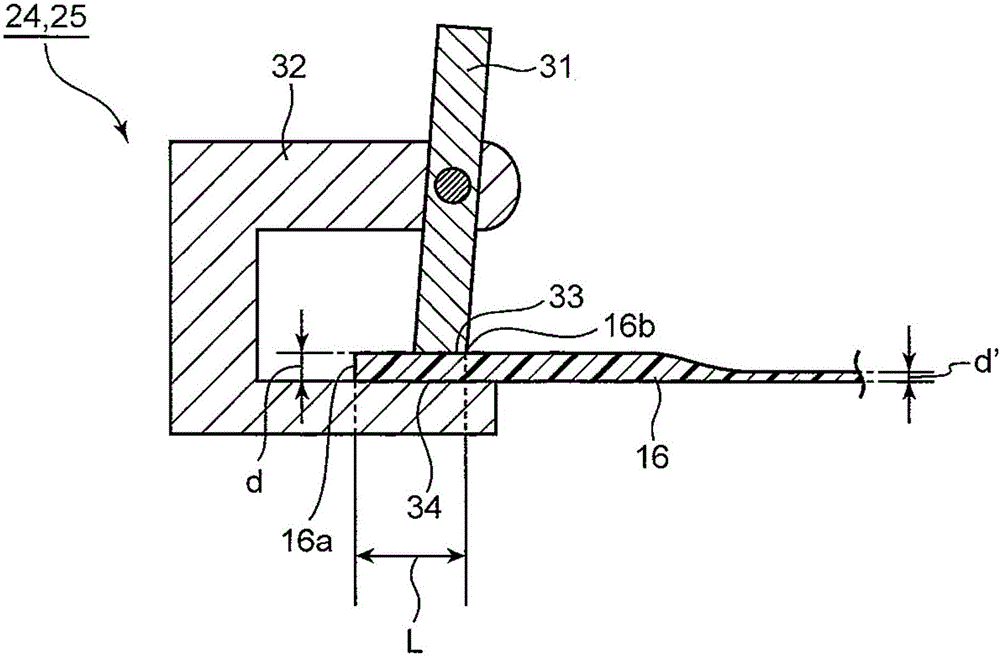

Assembled conductor and manufacturing method for assembled conductor

InactiveCN105321598ASuppression of distortionInhibition Manufacturing MethodNon-insulated conductorsReduction of cables/conductors sizeElectrical conductorEngineering

An assembled conductor and a manufacturing method for the assembled conductor are disclosed. The invention provides an assembled conductor (10), which is formed by rolling a conductor bundle (108) including a central conductor (2) and a peripheral conductor (1) arranged around the central conductor (2). The central conductor (2) has a shape in which a right-twisted portion (2a) of the central conductor and a left-twisted portion (2b) of the central conductor are arranged alternately in predetermined intervals (L1). The right-twisted portion (2a) of the central conductor extends from one end side (2d) of the central conductor (2) to the other end side (2e) of the central conductor (2) and is twisted in a clockwise direction, and the left-twisted portion (2b) of the central conductor (2) extends from the one end side (2d) of the central conductor (2) to the other end side (2e) of the central conductor (2) and is twisted in a counterclockwise direction. The peripheral conductor (1) is arranged around the central conductor (2) so that a twist direction of the peripheral conductor (1) becomes opposite to a twist direction of the central conductor (2).

Owner:TOYOTA JIDOSHA KK

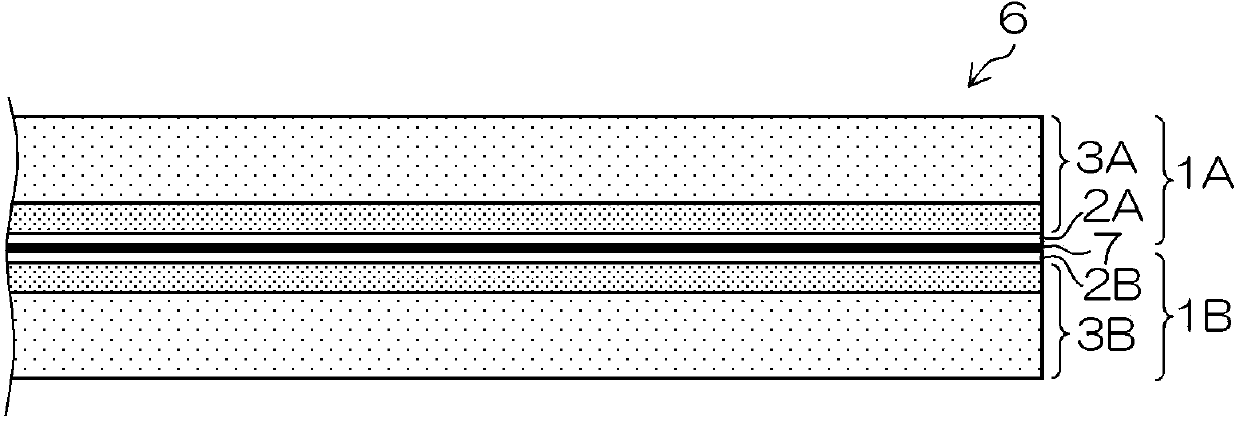

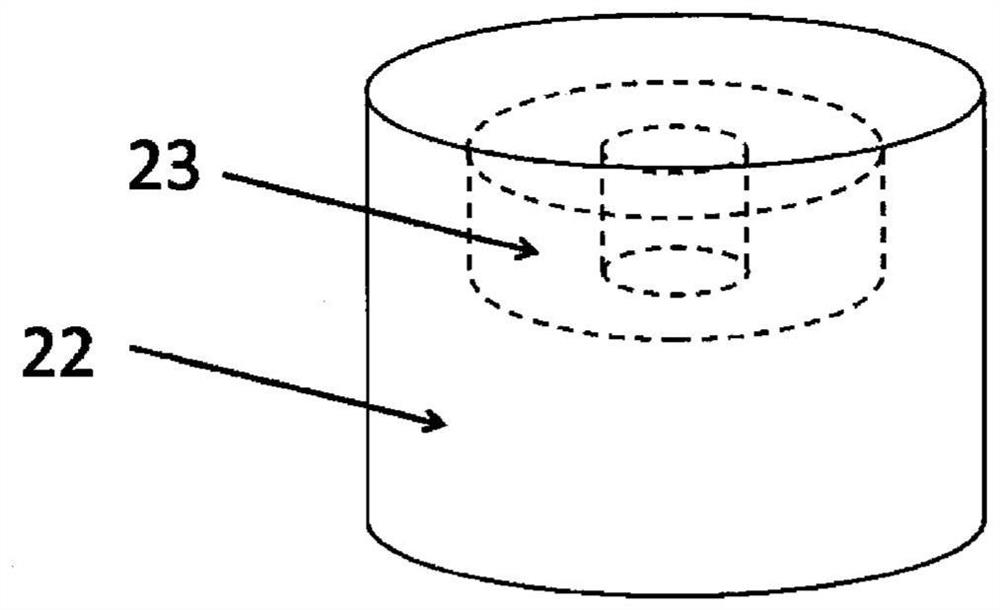

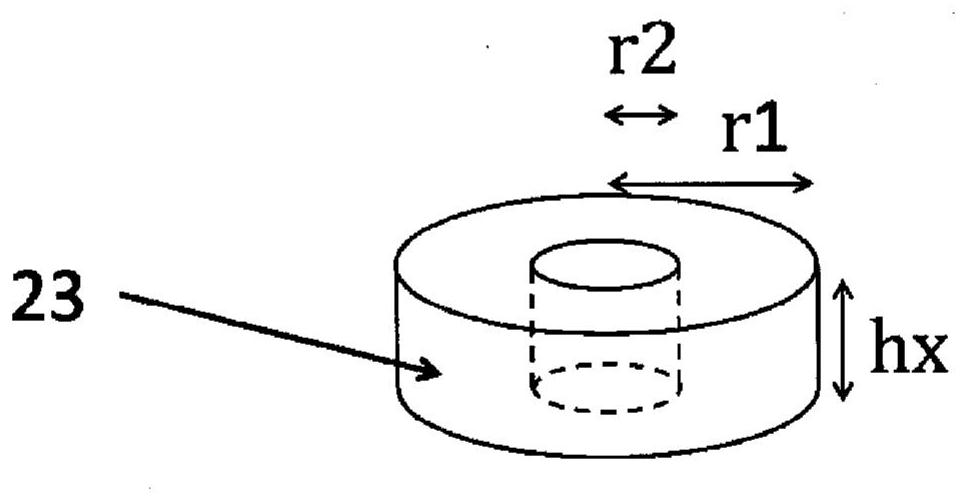

Sound-blocking sheet member, sound-blocking structure using same, and method for manufacturing sound-blocking sheet member

PendingCN112639959AImprove sound insulationEasy to prepareSynthetic resin layered productsCellulosic plastic layered productsEngineeringSoundproofing

The objective of the present invention is to provide a sound-blocking sheet member that has high sound-blocking performance exceeding the law of mass while being relatively lightweight, and has excellent manufacturability and durability. The sheet member has at least a sheet and a plurality of resonant parts. The resonant parts are provided in contact with a sheet surface of the sheet, and the resonant parts are provided with a weight section and a base section. The weight section is supported by the base section and has greater mass than the base section, and the weight section has a through portion. The base section makes contact with the surface of the weight section which is on the tip-end side of the resonant part, and covers the weight section.

Owner:MITSUBISHI CHEM CORP

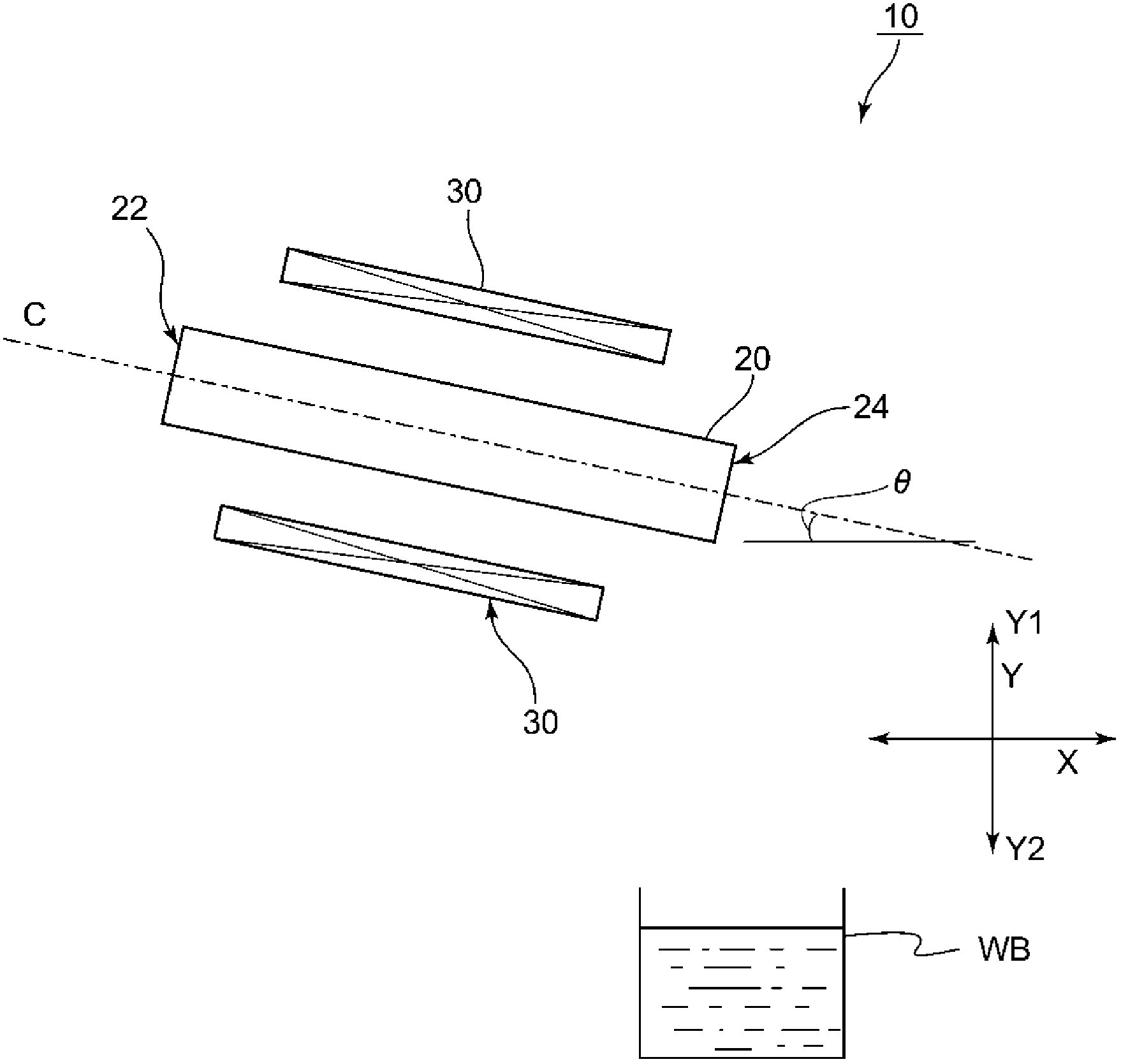

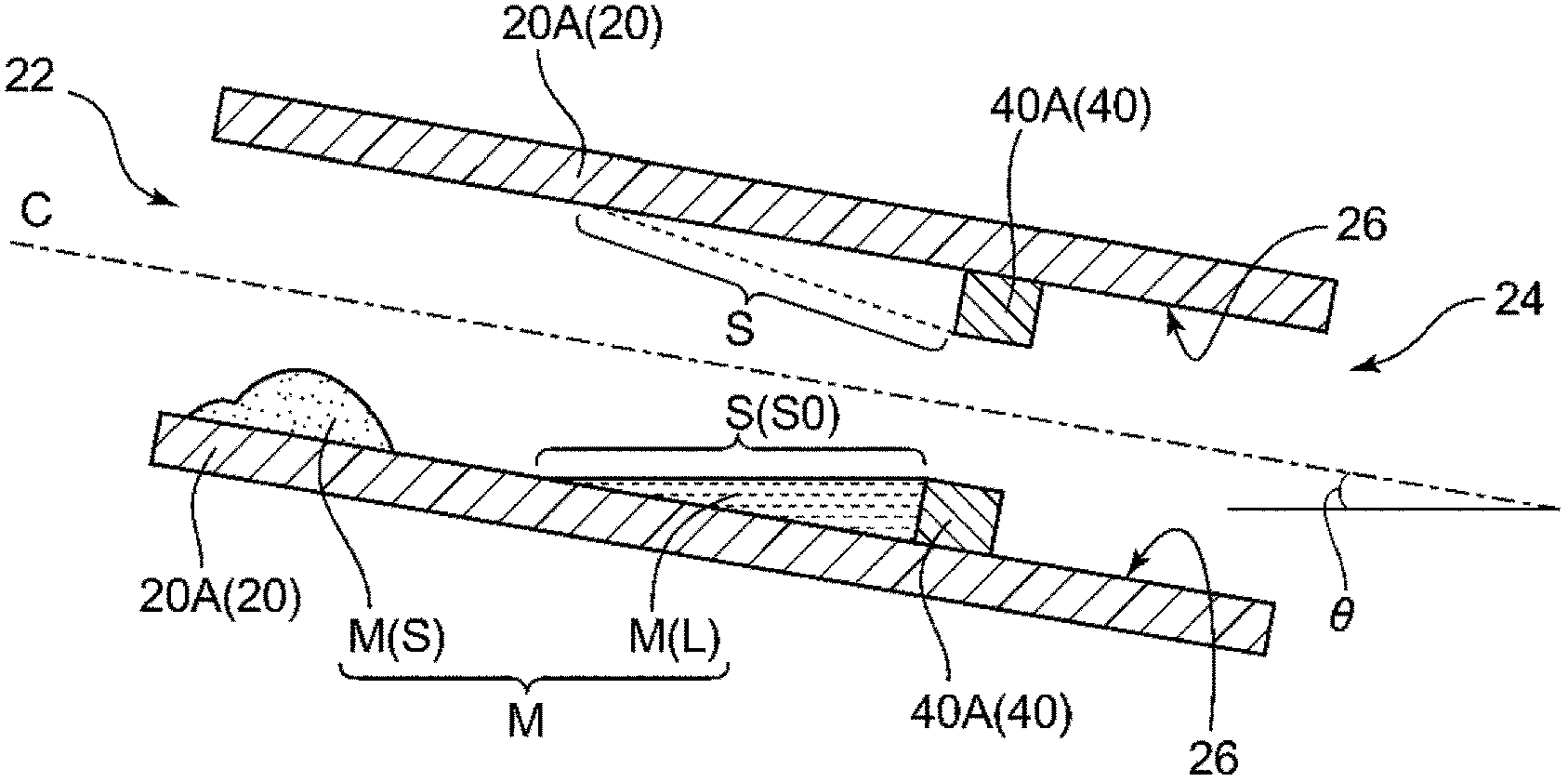

Method for manufacturing crude melt of glass raw materials and method for manufacturing optical glass

InactiveCN102910800AInhibition Manufacturing MethodGlass furnace apparatusMetallurgyMaterials processing

A method for manufacturing a crude melt of glass raw materials and a method for manufacturing optical glass by using the crude melt of glass raw materials, wherein the crude melt of glass raw materials can suppress coloring of the optical glass manufactured by using the crude melt of glass raw materials. The method of manufacturing the crude melt of the glass raw materials at least comprises: feeding the glass raw materials from the input port (22) of a material processing member (20) to the raw material feeding process in the material processing member (20), and enabling the glass raw materials fed to the material processing member (20) to move from the inlet(22) to the outlet (24), and performing a process of heating for melting, and a solidification process for solidifying the crude melt of the glass raw materials falling from the flow outlet (24) through cooling, to manufacture the crude melt of glass raw materials. Further, in the process of enabling the glass raw materials fed to the material processing member (20) to move from the inlet(22) to the outlet (24) side, the glass raw material is temporarily retained in the material processing member (20).

Owner:HOYA CORP

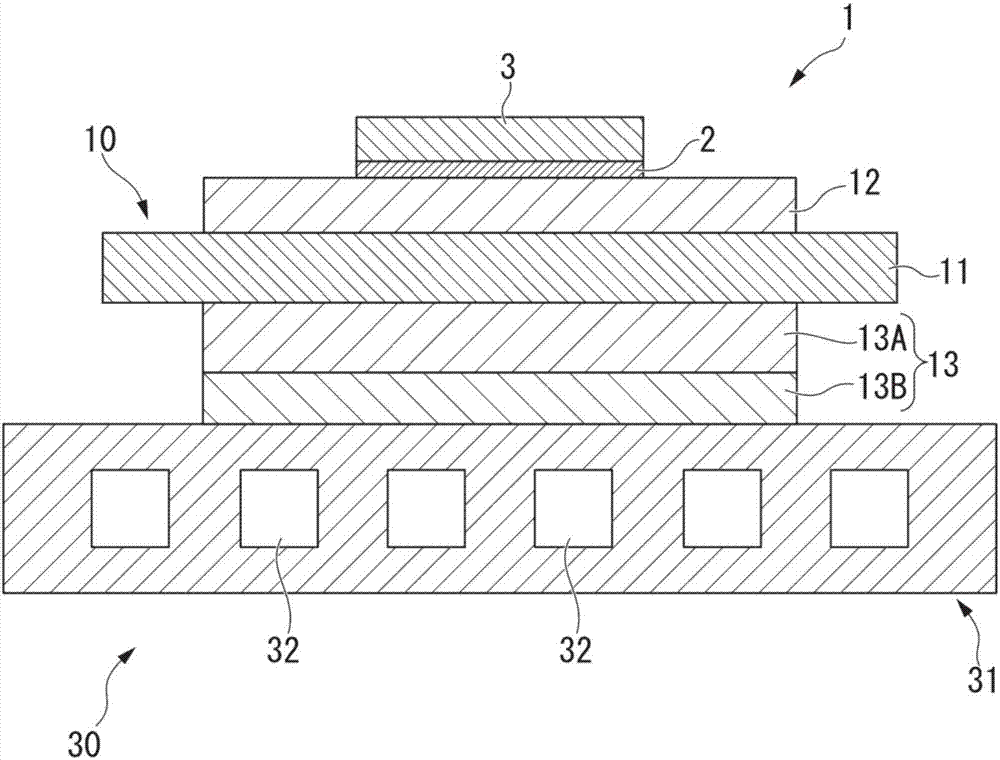

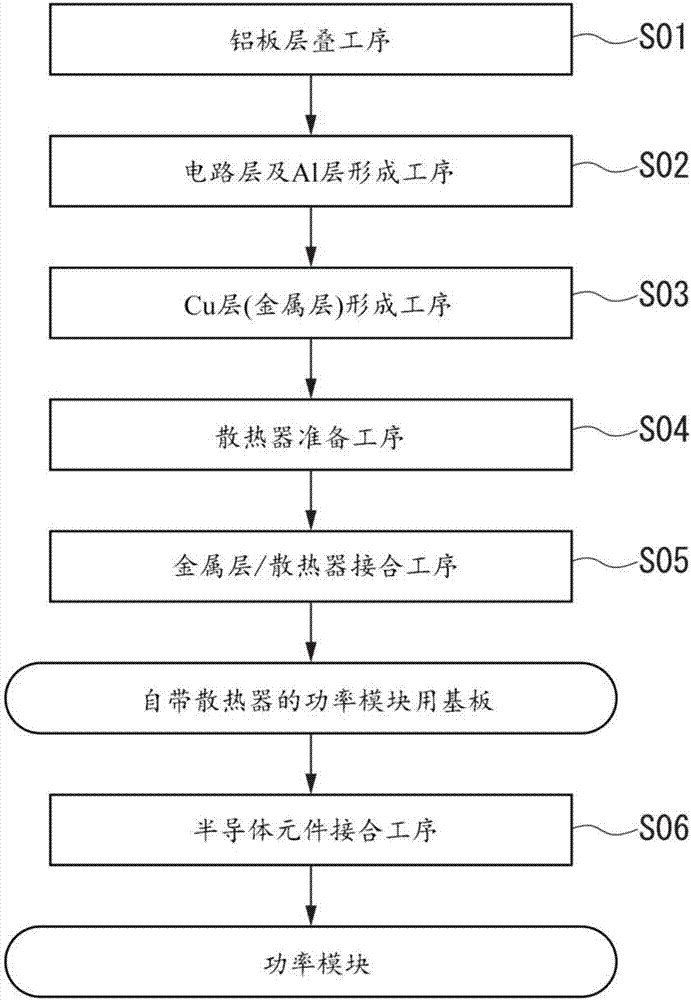

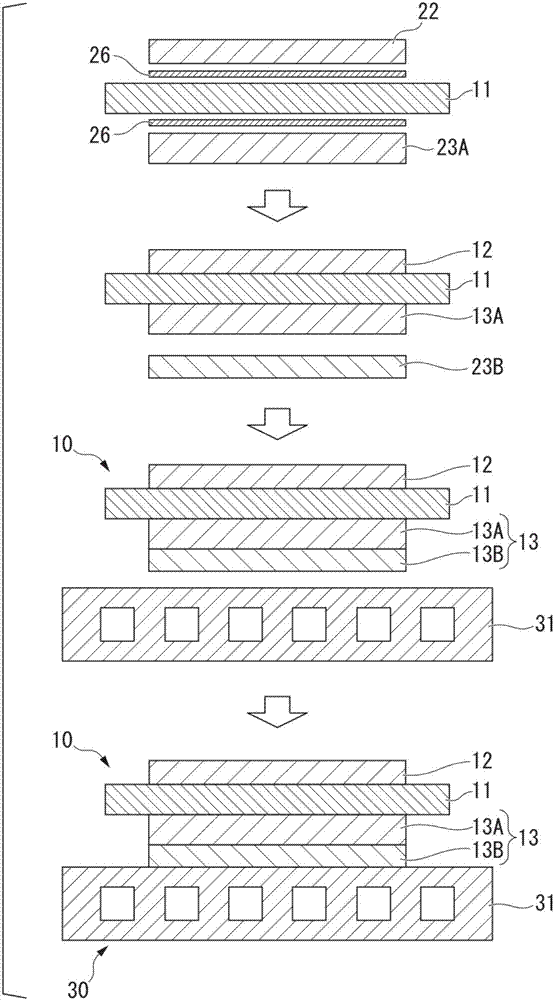

Manufacturing method for junction, manufacturing method for substrate for power module with heat sink, and manufacturing method for heat sink

ActiveCN107427954AOxidation effect is smallGood jointSemiconductor/solid-state device detailsSoldering apparatusCopper alloyHeat spreader

Provided is a manufacturing method for a junction formed by joining a copper member (13B) comprising copper or a copper alloy, and an aluminum member (31) comprising an aluminum alloy having an Si concentration in a range of not lower than 1 mass% and not higher than 25 mass%. The manufacturing method for the junction is characterized by: setting, in the aluminum member before joining, a circle equivalent diameter D90 of an Si phase in a junction surface with the copper member to be in a range of not smaller than 1 [mu]m and not larger than 8 [mu]m; and joining by solid phase diffusion the aluminum member and the copper member.

Owner:MITSUBISHI MATERIALS CORP

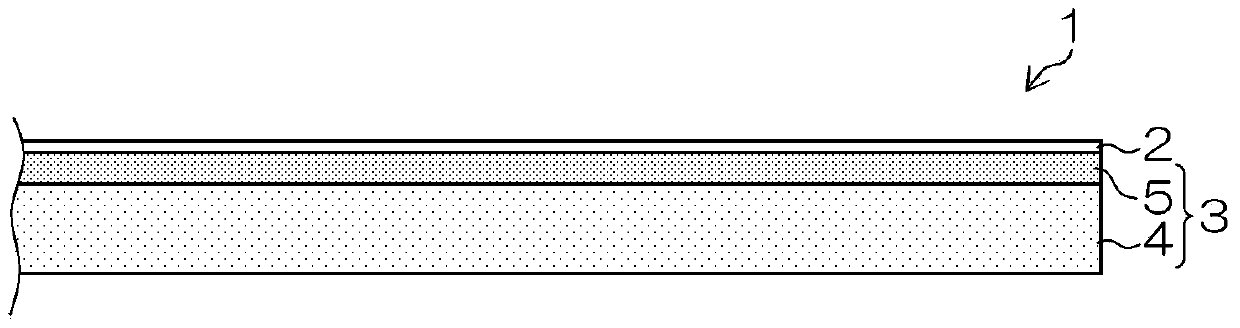

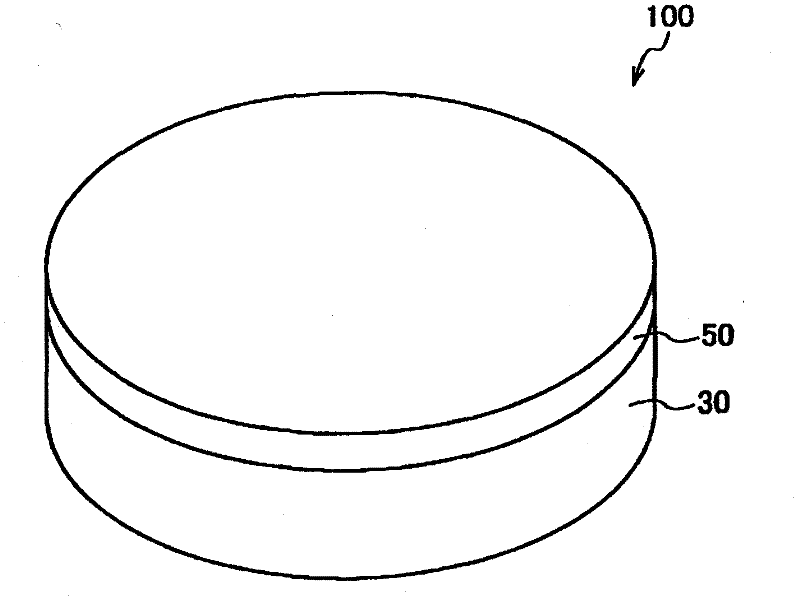

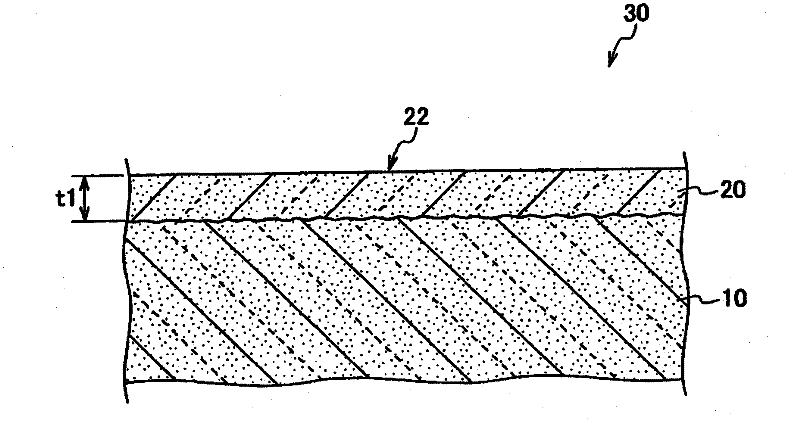

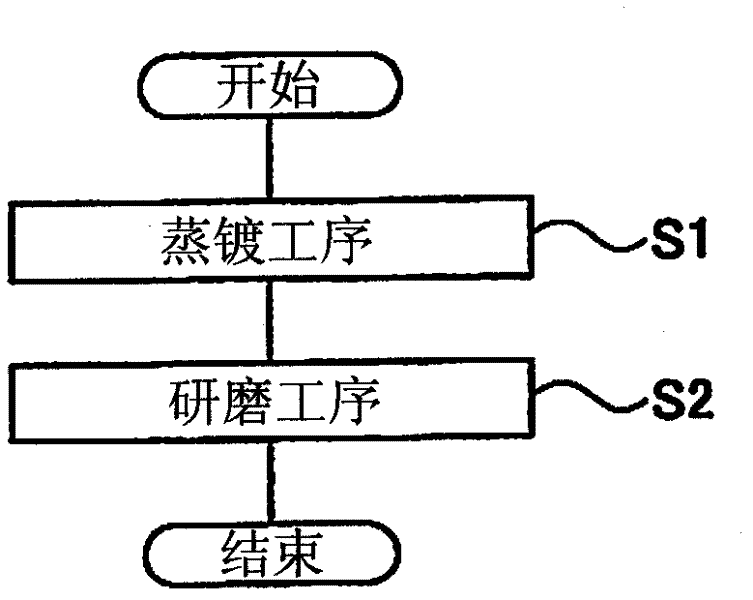

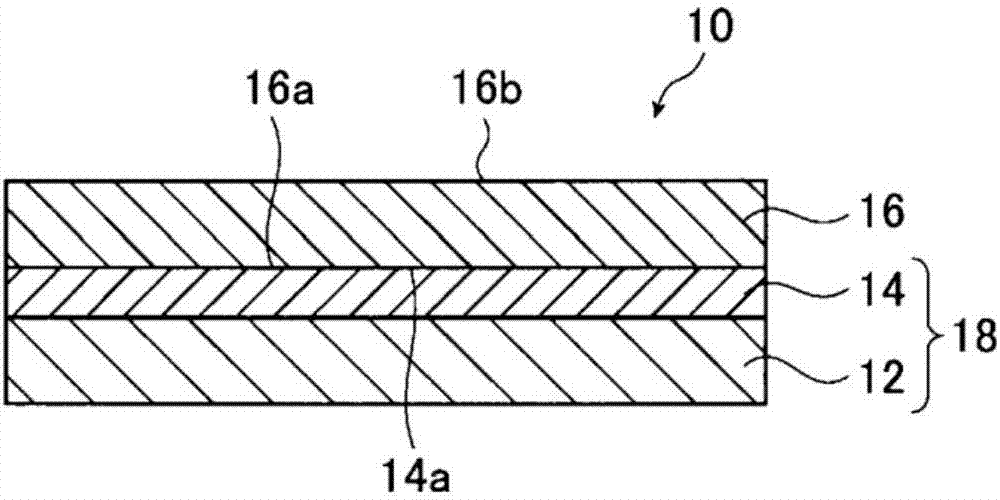

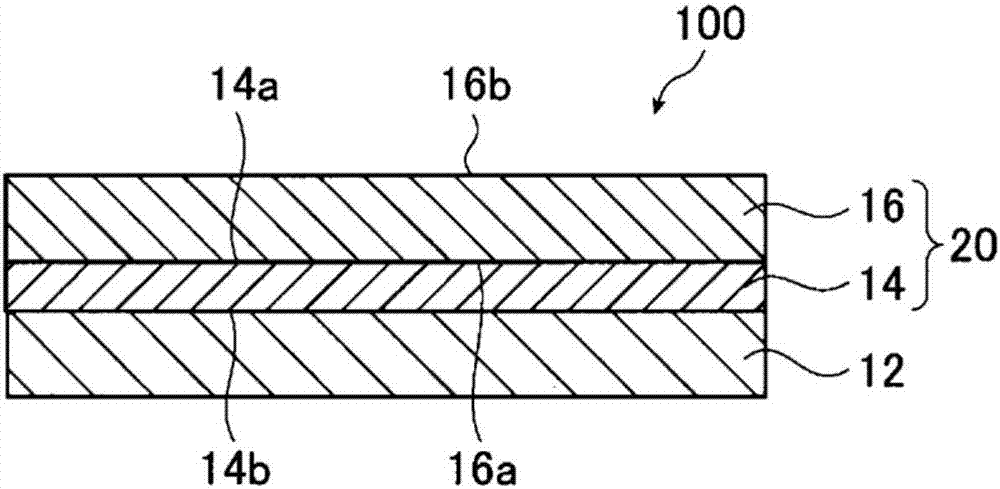

Supporting substrate, bonding substrate, method for manufacturing supporting substrate, and method for manufacturing bonding substrate

InactiveCN102378832AInhibition Manufacturing MethodPolycrystalline material growthAfter-treatment detailsSingle crystalSilicon

Provided is a supporting substrate (30) to be bonded on a single crystal wafer composed of a single crystal body. The supporting substrate is provided with a silicon carbide polycrystal substrate (10) composed of a silicon carbide polycrystal body, and a coat layer (20) deposited on the silicon carbide polycrystal substrate (10). The coat layer (20) is composed of silicon carbide or silicon and is in contact with the single crystal wafer, and the arithmetic average roughness of the contact surface (22) of the coat layer (20) in contact with the single crystal wafer is 1 nm or less.

Owner:BRIDGESTONE CORP

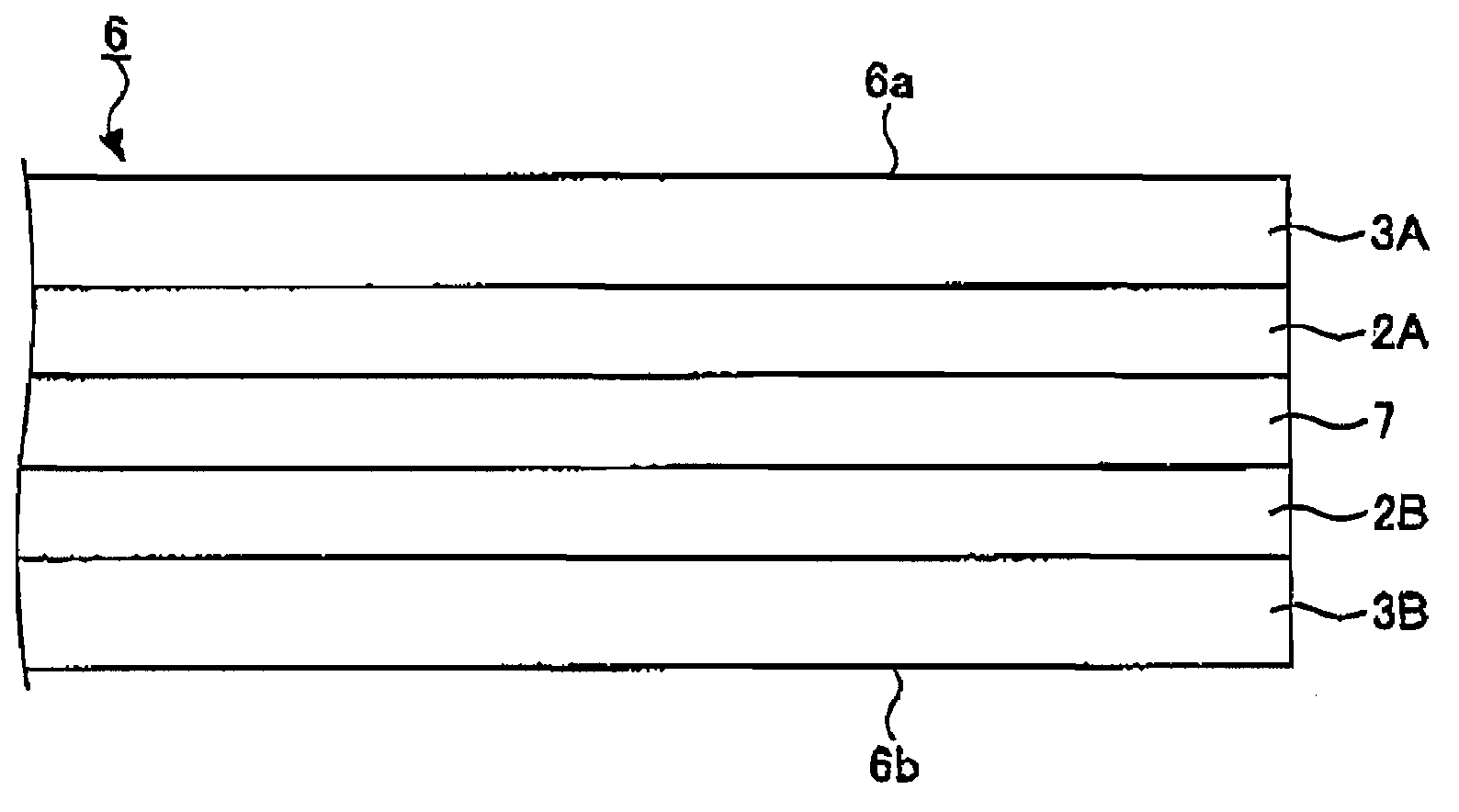

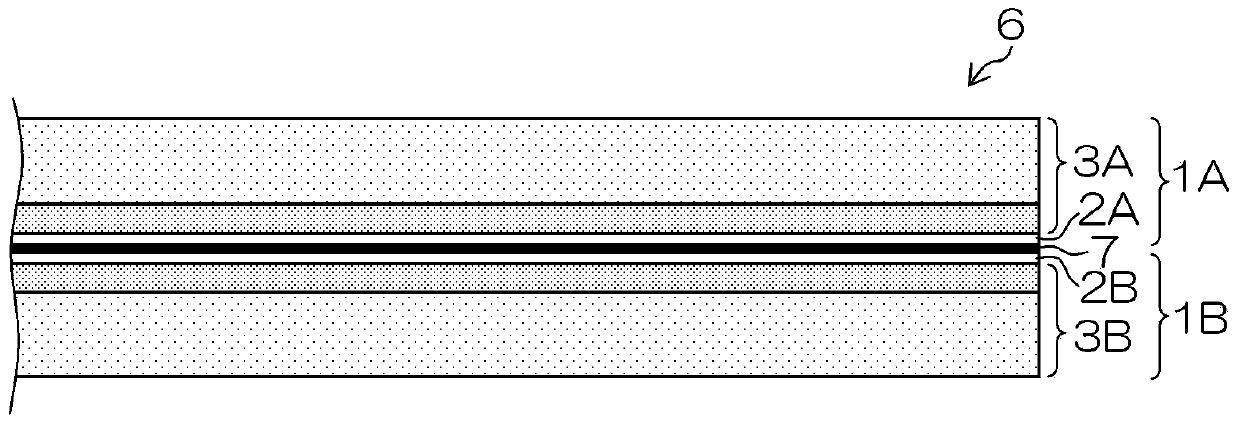

Glass laminate, method for producing electronic device, method for producing glass laminate, and glass plate package

InactiveCN107107568AInhibition of ruptureInhibition Manufacturing MethodElectrical equipmentGlass/slag layered productsOptoelectronicsUltimate tensile strength

Owner:AGC INC

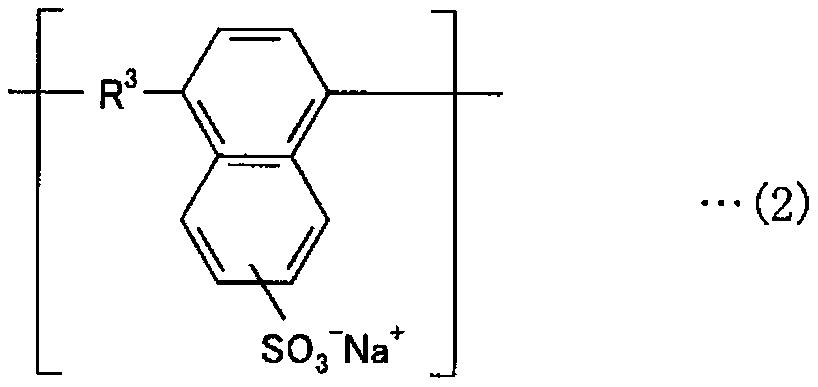

Method for manufacturing sulfolene compound and method for manufacturing sulfolane compound

ActiveCN102224146AInhibition Manufacturing MethodManufacturing method goes wellOrganic chemistrySulfolaneCarbon number

Disclosed is a method for manufacturing a sulfolene compound with which the production of polymers can be suppressed. Further disclosed is a method for manufacturing a sulfolane compound with which inhibition of the activity of a hydrogenation catalyst can be suppressed, allowing a sulfolane compound to be hydrogenated smoothly. The method for manufacturing a sulfolene compound is represented by formula (2) that comprises a step wherein a conjugate diene compound represented by formula (1) and sulfur dioxide are made to react in the presence of a metallocene compound. In formula (1), R<1>-R<6> independently represent a hydrogen atom or an alkyl group with a carbon number of 1-6. In formula (2), R<1>-R<6> represent the same groups as R<1>-R<6> in formula (1).

Owner:SUMITOMO SEIKA CHEM CO LTD

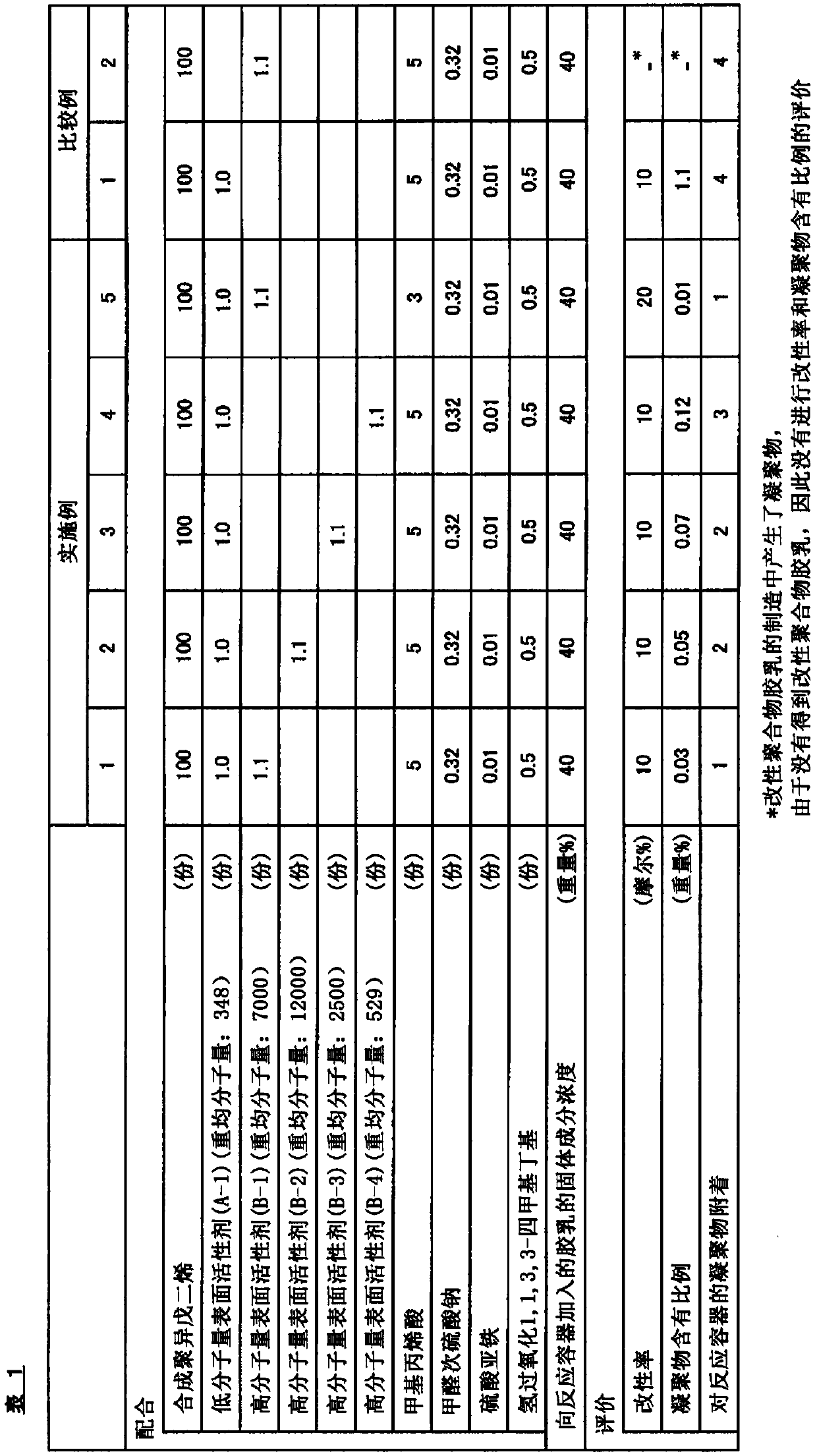

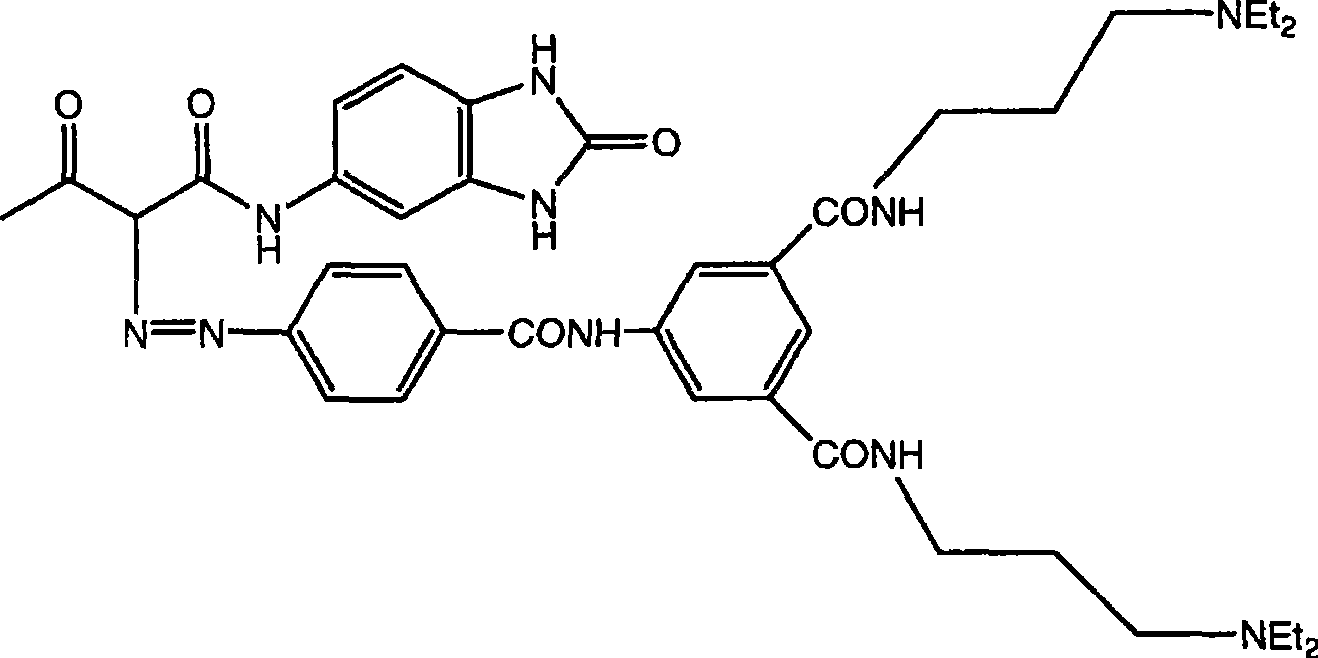

Modified polymer latex production method

A production method of a modified polymer latex is provided which involves adding a carboxy group-containing compound, an anionic surfactant with a weight average molecular weight less than 500 and ananionic surfactant with a weight average molecular weight greater than or equal to 500 to a polyisoprene latex, and reacting the carboxy group-containing compound with the polyisoprene in the presence of the anionic surfactant with a weight average molecular weight less than 500 and the anionic surfactant with a weight average molecular weight greater than or equal to 500.

Owner:ZEON CORP

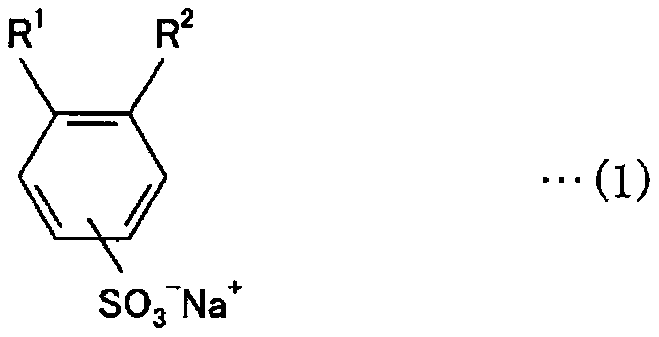

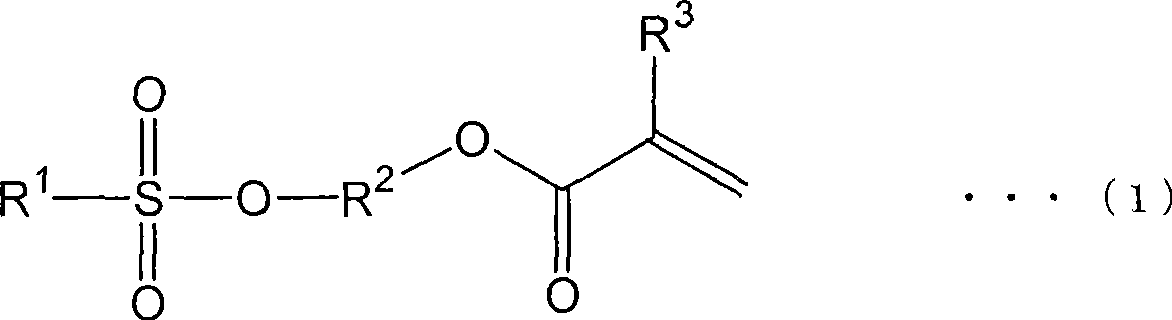

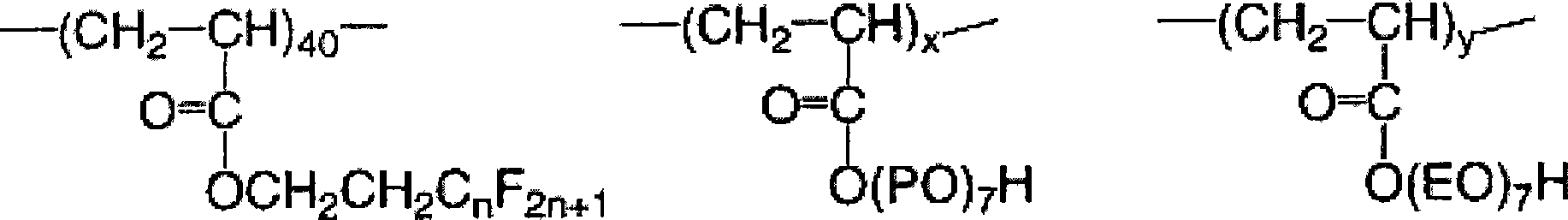

Method for producing (meth)acrylate and (meth)acrylate composition

ActiveCN101437786AGood storage stabilityImprove thermal stabilityOrganic compound preparationOrganic chemistry methodsCompound aOrganic sulfonic acid

Disclosed is a simple method for producing a (meth)acrylate which enables to obtain a (meth)acrylate improved in storage stability and thermal stability. Also disclosed is a (meth)acrylate composition. The production method comprises an esterification step wherein a (meth)acrylic acid and an alcohol having an oxyalkylene group are dehydrated with an organic sulfonic acid catalyst in an organic solvent, thereby obtaining a (meth)acrylate; and an adjustment step wherein a compound A represented by the formula (1) below is controlled to be 0-100 ppm in the thus-obtained (meth)acrylate. The production method also comprises an addition step wherein a specific processing agent is added into an organic reaction liquid which contains not less than 1 ppm of the compound A relative to the (meth)acrylate obtained through the esterification step and a step for performing neutralization and water rinsing. (1) [In the formula (1), R1 represents an alkyl group or an aryl group; R2 represents an alkylene group; and R3 represents a hydrogen atom or a methyl group.

Owner:TOAGOSEI CO LTD

Color filter manufacturing method

ActiveCN101382613AReduce planar failuresInhibition Manufacturing MethodOptical filtersPhotomechanical apparatusChemistryCoating

The invention relates to a method of manufacturing color filter capable of reducing facet fault of the coating film and restraining the occurrence of the fault; wherein, the method comprises: first filtering procedure of filtering the light-sensitive resin composition at the filtering speed of above 0.1 ml / min.cm2 and below 1.0 ml / min.cm2 through the first filter; and a second filtering procedure of further filtering the light-sensitive resin composition at the filtering speed of above 30 ml / min.cm2 and below 200 ml / min.cm2 through the second filter after the first filtering procedure; and a coating procedure of coating the light-sensitive resin composition filtered by the second filtering procedure on the substrate.

Owner:FUJIFILM CORP

Inductor and manufacturing method thereof

ActiveCN111755208AInhibition Manufacturing MethodTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInductorMechanical engineering

The invention provides an inductor and a method for manufacturing the inductor, which can suppress the occurrence of short circuit failure between the external terminal and a part of a coil except forthe part connected with the external terminal. The inductor includes a body including a magnetic body having a coil embedded therein and containing magnetic powder. The coil has a winding portion inwhich a conductive wire is wound around and has a pair of lead portions taken out from the winding portion. The inductor also includes a pair of outer electrodes formed on the body. In the inductor, each of the lead portions is exposed from at least one side surface of the magnetic body and is coupled to a corresponding outer electrode. In addition, with respect to a position at which each of thelead portions is exposed from the at least one side surface of the magnetic body, a magnetic powder content in a region closer to one of the principal surfaces is higher than a magnetic powder contentin a region closer to the other one of the principal surfaces.

Owner:MURATA MFG CO LTD

Method for producing resin film

ActiveCN106256525AInhibitionInhibition Manufacturing MethodFlat articlesCoatingsEngineeringMechanical engineering

Owner:KONICA MINOLTA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com