Method of manufacturing negative electrode for solid-state battery, method of manufacturing solid-state battery, and negative electrode slurry

A manufacturing method and technology for solid-state batteries, which are applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problem of inability to take into account the suppression of sulfide-based solid electrolytes, capacity deterioration, and insufficient adhesion between current collectors and electrode layers, etc. problem, to achieve the effect of suppressing capacity deterioration and suppressing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] 1. Issues with conventional adhesives

[0081] When using a copolymer containing a three-component system of VDF monomer unit, TFE monomer unit and HFP monomer unit as a binder to make a negative electrode, and using the negative electrode to make a solid battery and charge and discharge, the initial charge is at 3V A plateau caused by side reactions was observed nearby, and the capacity of the battery decreased. When intensive research was carried out, it was presumed that the TFE component contained in this binder was reductively decomposed at the time of initial charging. Therefore, application to an adhesive of a two-component system containing VDF and HFP except for the TFE component has been attempted.

[0082] 2. Preparation of negative electrode

[0083] 2.1. Preparation of binder solution

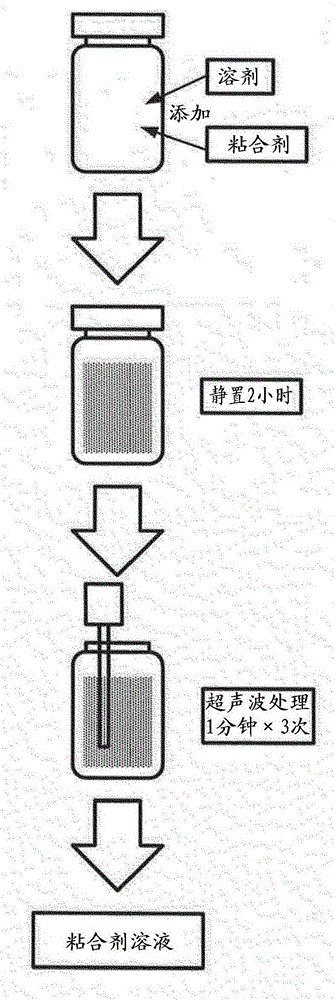

[0084] pass figure 1 The procedure shown in , prepare the binder solution. details as follows.

preparation example 1

[0085] (Preparation Example 1) Powder of polyvinylidene fluoride (PVDF, VDF 100%) was added to butyl methacrylate (manufactured by Kishida Chemical Co., Ltd.), and stirred overnight to prepare a binder solution (1). Here, the whole of the binder solution (1) was regarded as 100% by mass, and it was operated so as to contain 20% by mass of the binder. Note that, since PVDF cannot be dissolved and dispersed in butyl butyrate, butyl methacrylate was used instead of butyl butyrate as a solvent for the binder solution.

preparation example 2

[0086] (Preparation Example 2) A binder powder of a three-component system prepared by copolymerization at a ratio of VDF:TFE:HFP=55 mol%:25 mol%:20 mol%, was added to butyl butyrate (Kishida Chemical Co., Ltd. Co., Ltd.) was stirred overnight to dissolve the binder to prepare a binder solution (2). Here, the whole of the binder solution (2) was regarded as 100% by mass, and it was operated so as to contain 5% by mass of the binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com