Heat radiation plate, semiconductor device and manufacturing method of heat radiation plate

A manufacturing method and heat dissipation plate technology, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as reduced jointability, cracks, and inability to bond semiconductor elements well, and achieve improved The effect of bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

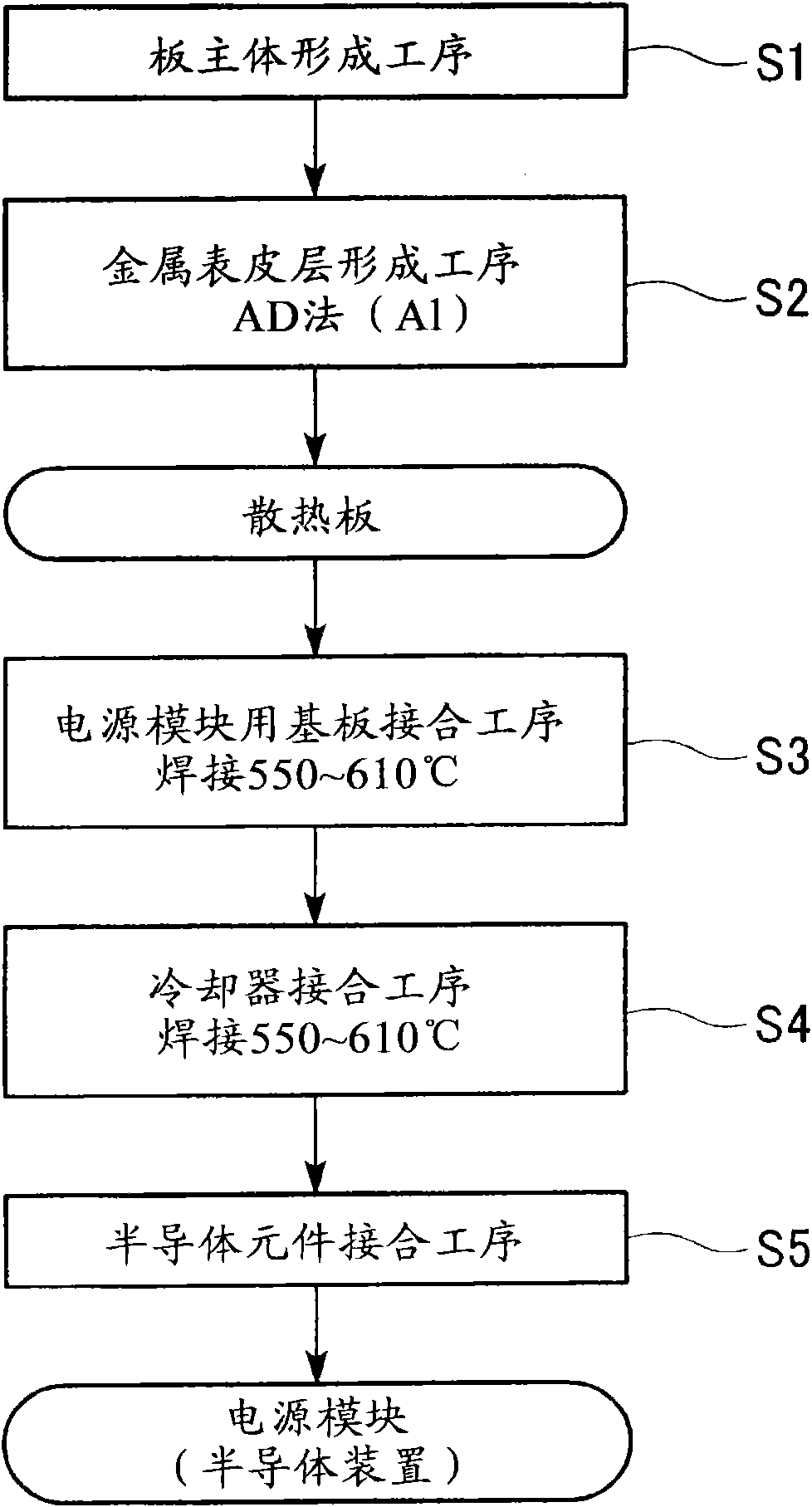

[0058] First, refer to Figure 1 to Figure 4 , a power module (semiconductor device) using the heat sink according to the first embodiment of the present invention will be described.

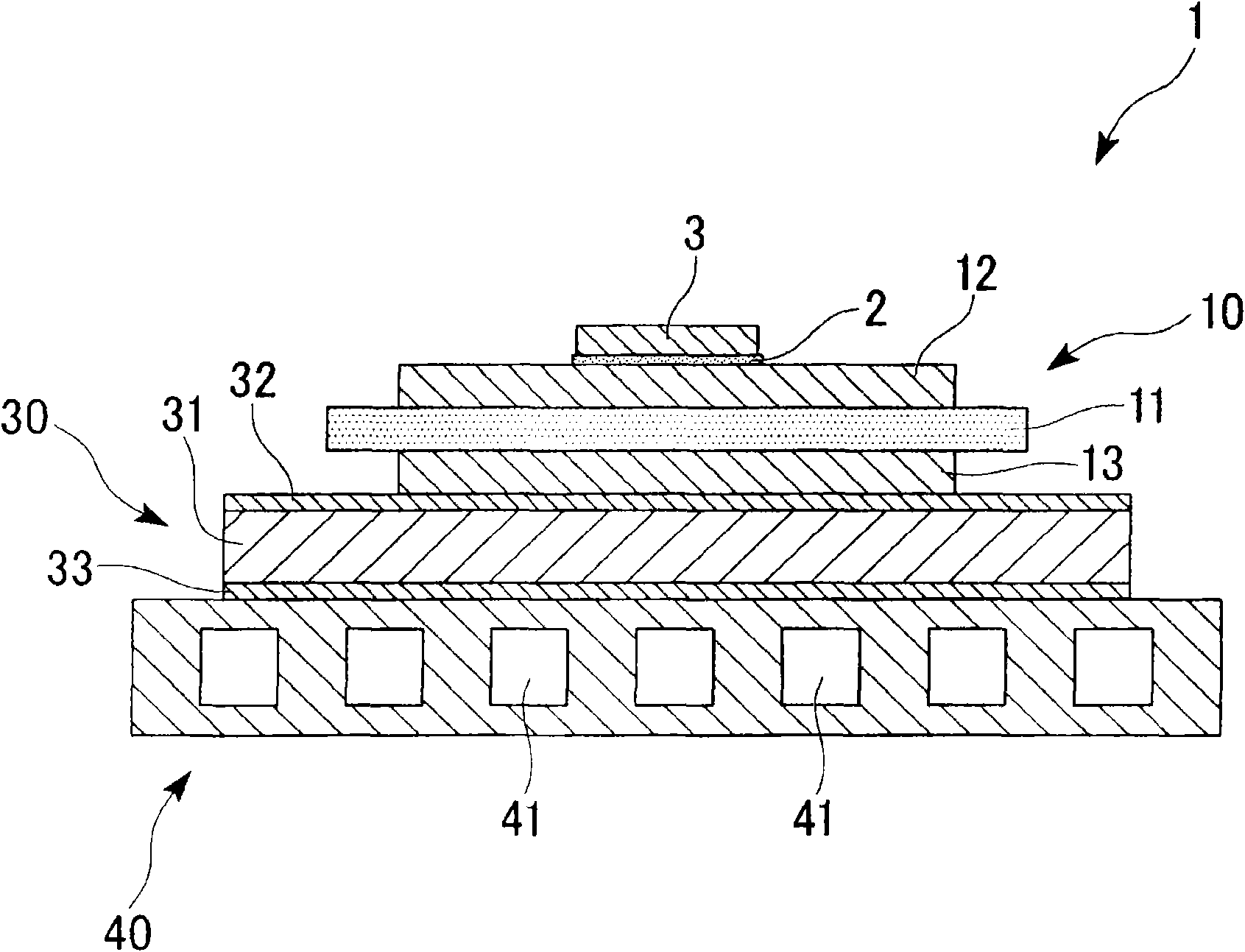

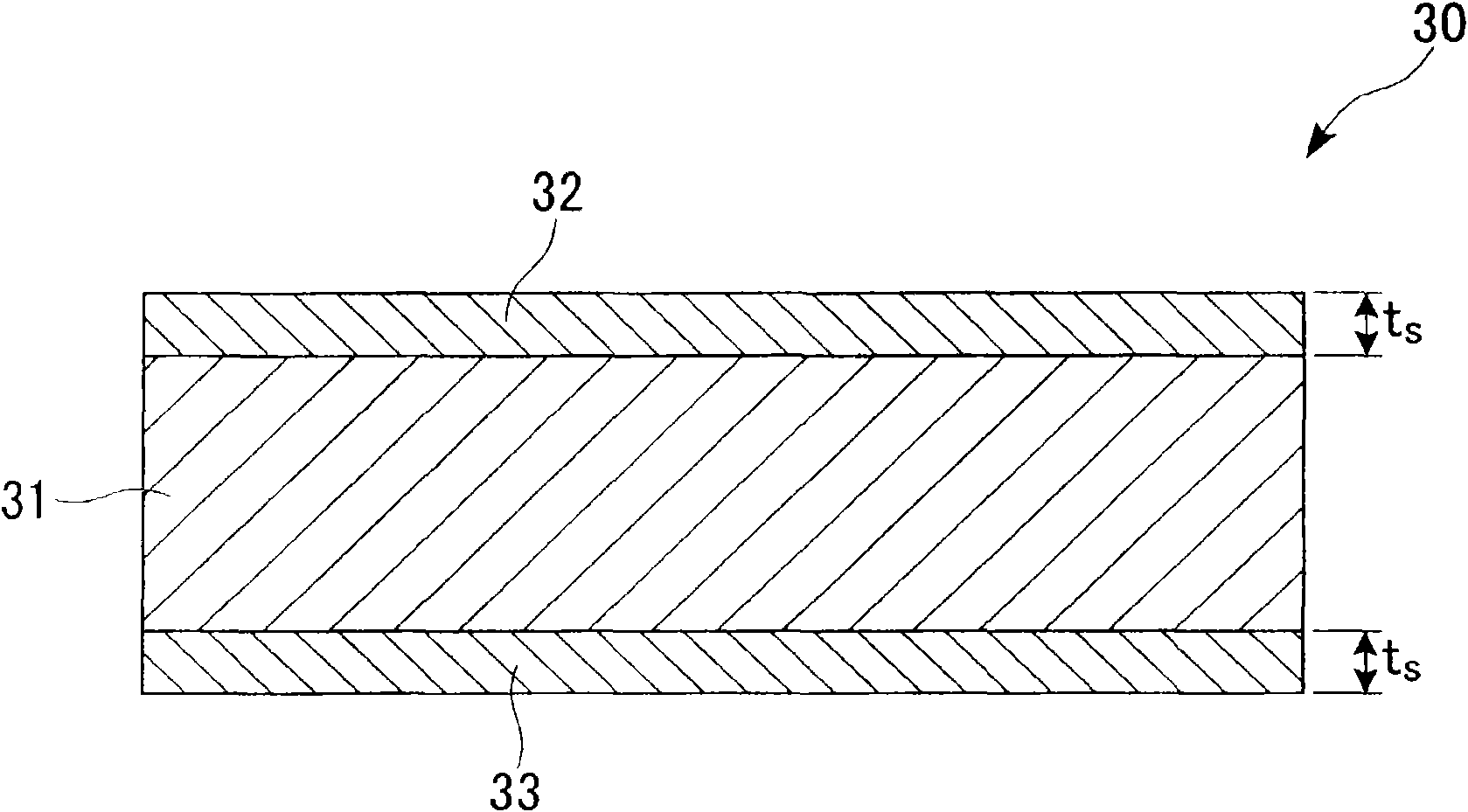

[0059] figure 1 The illustrated power module 1 includes a power module substrate 10, and on one side of the power module substrate 10 (in figure 1 The upper side in the center) the semiconductor chip 3 bonded by the solder layer 2 is arranged on the other side of the power module substrate 10 (on the figure 1 The center is the lower side) of the heat sink 30 and the cooler 40 arranged on the other side of the heat sink.

[0060] The power module substrate 10 includes a ceramic substrate 11, and is disposed on one side of the ceramic substrate 11 (in figure 1 The circuit layer 12 on the top) and the other side of the ceramic substrate 11 (in the figure 1 The middle is the metal layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com