Color filter manufacturing method

A manufacturing method and color filter technology, applied in the field of color filter manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

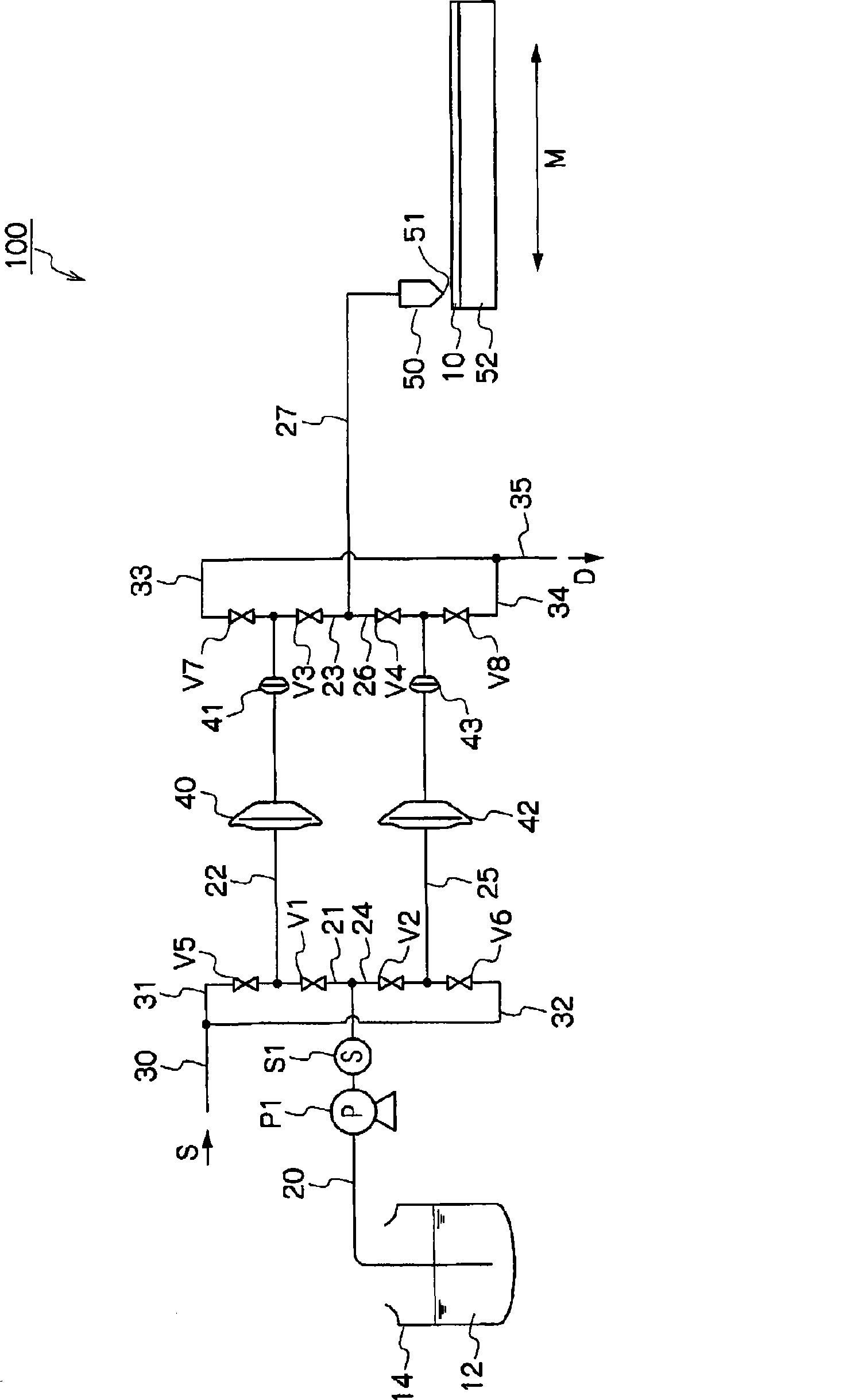

[0057] As a preferred embodiment of the manufacturing method of the color filter of the present invention, for example, use such as figure 1 An embodiment of the coating device 100 is shown.

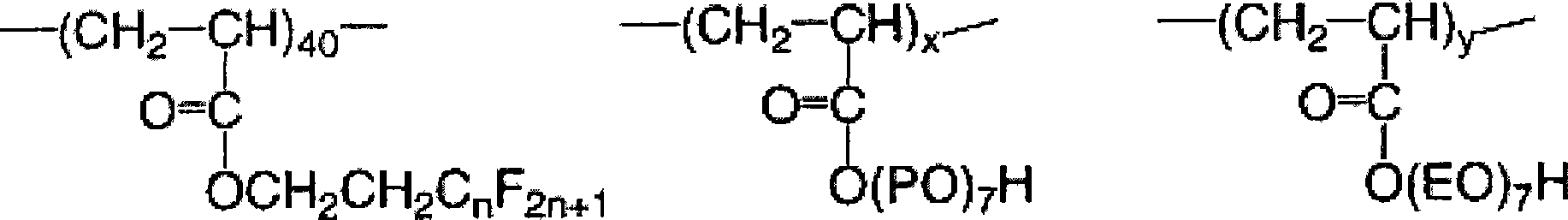

[0058] according to figure 1 In the illustrated embodiment, the resist solution 12 in the resist solution tank 14 passes through the supply pipe 20, and the resist solution 12 passing through the supply pipe 20 then passes through the first pipeline (with the supply pipe 21, equipped with the filter device 40 and the supply pipe 22 of the filter device 41, and the path of the supply pipe 23) and / or the second pipeline (having the supply pipe 24, the supply pipe 25 equipped with the filter device 42 and the filter device 43, and the path of the supply pipe 26), The resist solution 12 passing through the first pipeline and / or the second pipeline is then supplied to the slit nozzle 50 through the supply pipe 27, and the provided resist solution 12 is supplied by the slit nozzle 50. The ej...

Embodiment 1

[0188]

[0189] The dark-colored photosensitive resin composition K1 as a curable composition can be obtained in the following manner, that is, firstly, by measuring the amount of K pigment dispersion 1, propylene glycol monomethyl ether acetate , mixed at a temperature of 24°C (±2°C), stirred at 150rpm for 10 minutes, and then weighed the amount of butanone, binder 1, hydroquinone monomethyl ether, DPHA liquid, 2,4 -bis(trichloromethyl)-6-[4'-(N,N-bisethoxycarbonylmethyl)amino-3'-bromophenyl]-s-triazine and surfactant 1, at a temperature of 25 °C (±2°C) was added sequentially, and stirred at a temperature of 40°C (±2°C) and 150 rpm for 30 minutes.

[0190] However, the amounts described in Table 1 are parts by mass, and are specifically the following compositions.

[0191] [K Pigment Dispersion 1]

[0192] ・Carbon black (Nipex 35 manufactured by Dixon Co., Ltd.) ... 13.1 parts

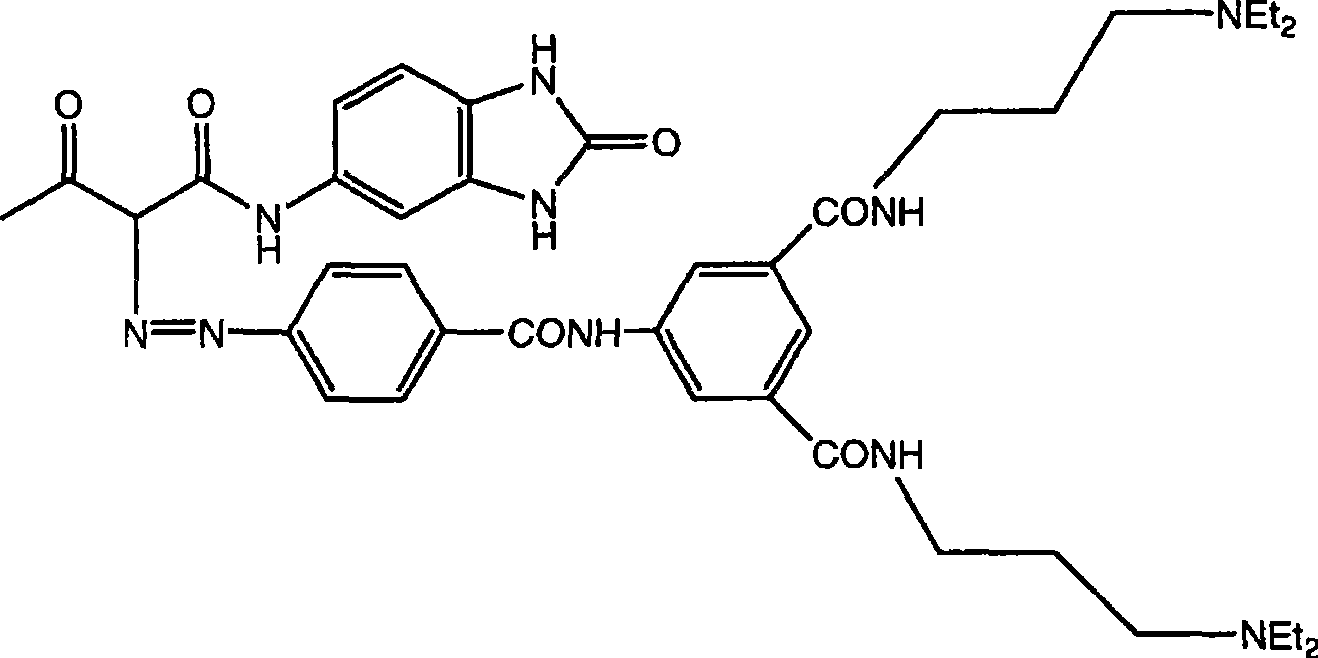

[0193] ・Dispersant (compound (1) below) ... 0.65 parts

Embodiment 2~19、 comparative example 1~4

[0244] As shown in Table 2, except for changing the filtration rate, filter material, and filter pore size in the first filtration step and the second filtration step, a color filter was produced in the same manner as in Example 1, and evaluated in the same manner as in Example 1. . The evaluation results are shown in Table 2.

[0245] In addition, the adjustment of the filtration rate was performed by changing the filtration area of the 1st and 2nd filter, or the liquid-feeding speed with respect to the dark-color photosensitive resin composition K1 by the resist liquid liquid-feeding pump P1.

[0246] [Table 2]

[0247]

[0248] "Description of symbols in the table"

[0249] ※1...PP means polypropylene

[0250] ※2...The unit of filtration speed is "ml / min·cm 2 "

[0251] As can be seen from Table 2, in Examples 1 to 19 using the manufacturing method of the filter of the present invention, the occurrence of defects was suppressed.

[0252] In addition, in the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com