Inductor and manufacturing method thereof

A manufacturing method and inductor technology, applied in the direction of inductor, inductor/transformer/magnet manufacturing, fixed inductor, etc., can solve problems such as short circuit of inductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

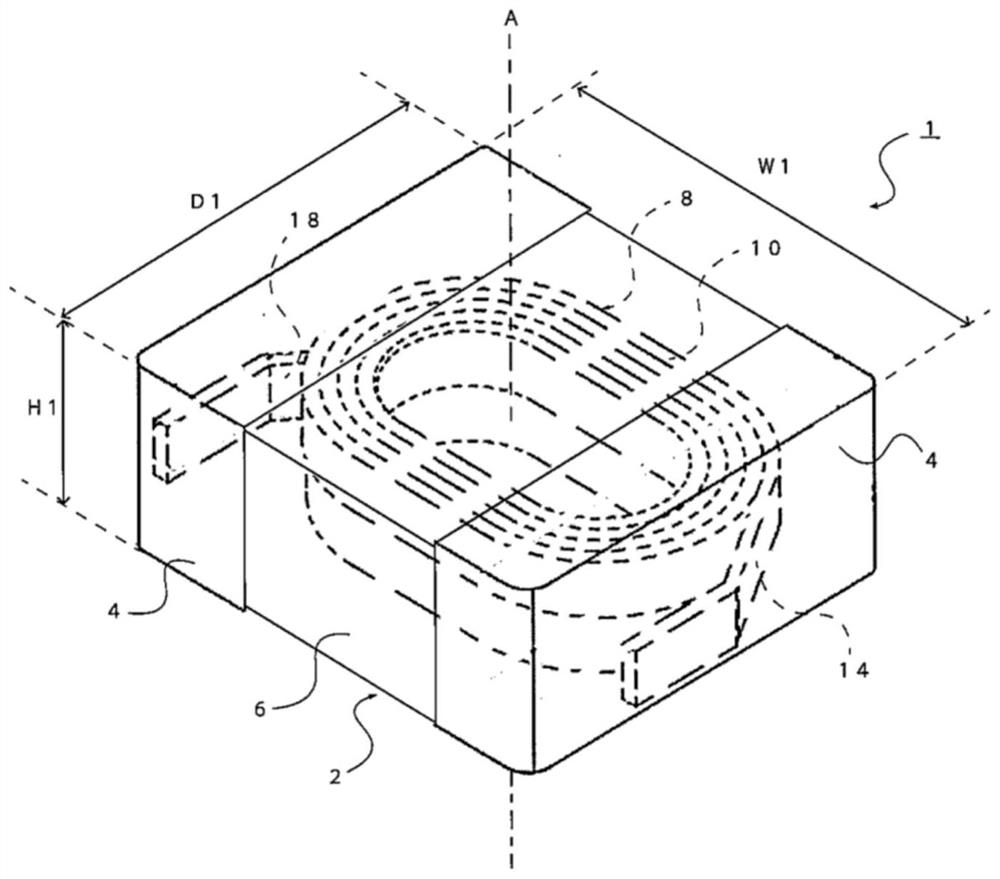

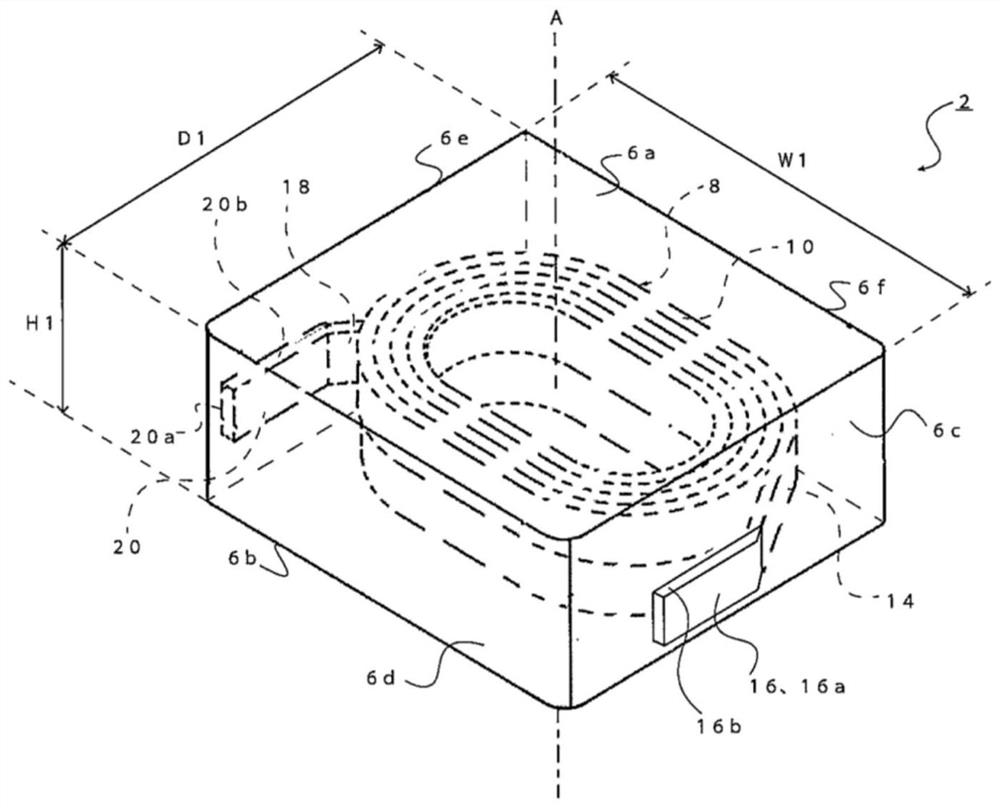

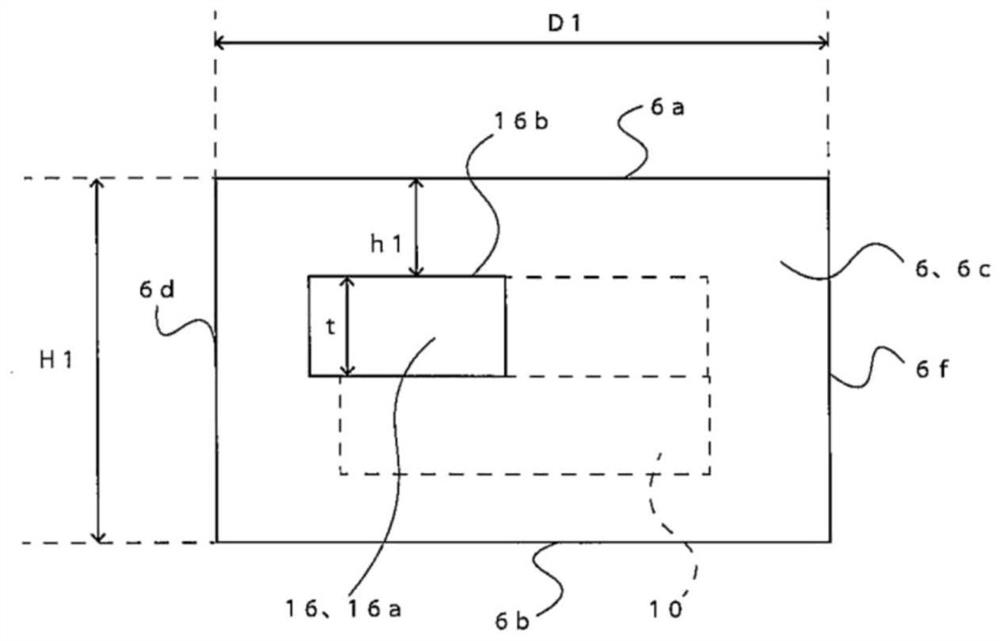

[0038] refer to figure 1 and figure 2 The inductor according to Embodiment 1 of the present invention will be described. figure 1 It is a perspective view which shows the inductor 1 which concerns on Embodiment 1 of this invention. figure 2 yes means figure 1 A perspective view of the body 2 of the inductor 1 is shown.

[0039] The inductor 1 includes: a main body 2 including a magnetic body 6 of magnetic powder and a coil 8 embedded in the magnetic body 6 ; and a pair of external terminals 4 formed on the surface of the main body 2 . The magnetic body 6 has a substantially rectangular parallelepiped shape having two opposing main surfaces 6a, 6b and a plurality of (here, four) side surfaces 6c, 6d, 6e, 6f. The coil 8 has a winding portion 10 formed by winding a conductive wire, and a pair of lead-out portions 14 and 18 drawn from the winding portion 10 . At least parts of the lead portions 14 and 18 are exposed from the side surfaces of the magnetic body 6 and are conn...

Embodiment approach 2

[0069] Next, refer to Figure 10 Inductor 101 according to Embodiment 2 will be described. Figure 10 It is a perspective view explaining the coil 108 and the 3rd area|region 30 of the main body 102 of the inductor 101 concerning Embodiment 2 of this invention. Inductor 101 differs from inductor 1 according to Embodiment 1 in that end portions 116 and 120 of a pair of lead portions 114 and 118 are also exposed from one side surface 106 d in the longitudinal direction of magnetic body 106 . Furthermore, the arrangement of the region with a high magnetic powder filling rate is also different from that of the inductor 1 according to the first embodiment. Hereinafter, differences from the inductor 1 according to Embodiment 1 will be described in detail.

[0070] End portions 116 , 120 of lead-out portions 114 , 118 drawn out from winding portion 100 are also exposed on one side surface 106 d in the longitudinal direction of magnetic body 106 . The lead-out parts 114, 118 are be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com