Method of manufacturing magnetic element and magnetic element

A technology of magnetic components and manufacturing methods, applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of complicated closed magnetic circuit assembly, defective or damaged magnetic cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

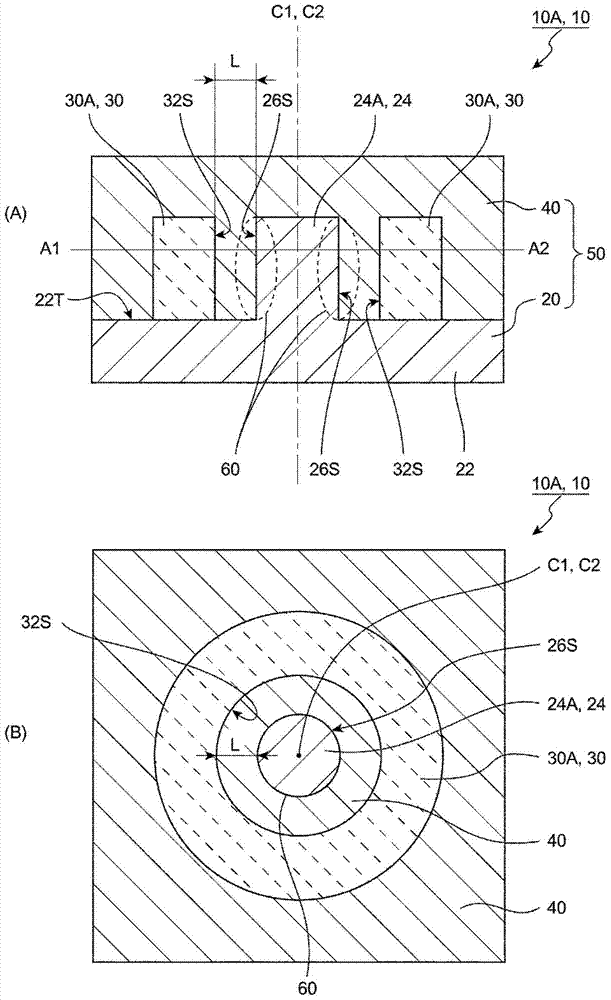

[0075] figure 1 It is a schematic diagram which shows an example of the magnetic element manufactured by the manufacturing method of the magnetic element of this embodiment. here, figure 1 (A) is a schematic cross-sectional view when the magnetic element is cut along a plane including the central axis of the core part of the first magnetic core member, figure 1 (B) is the plane that intersects the magnetic element perpendicular to the central axis of the core ( figure 1 (A) A schematic side view when the symbol A1-A2) is cut off.

[0076] figure 1 The shown magnetic element 10 has a first magnetic core part 20, a winding part 30A (30), and a second magnetic core part 40, wherein the first magnetic core part 20 has a substantially plate-shaped base part 22 and The core portion 24A ( 24 ) protruding from the substantially central portion of one surface (upper surface 22T) of the base portion 22 and the wire winding portion 30A ( 30 ) are formed into a cylindrical body by win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com