Production method for hot press molded articles, press molded article, die mold and mold set

A technology of hot press forming and manufacturing method, which is applied in the fields of manufacturing hot press forming products, press forming products, die dies and die sets, and can solve problems such as processing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0285] Next, the present application will be further described while showing examples. It should be noted that the present application is not limited to the examples shown below.

[0286] "Manufacturing of plated steel sheets"

[0287]

[0288] In a cold-rolled steel sheet with a thickness of 1.6mm (by mass%, C: 0.21%, Si: 0.12%, Mn: 1.21%, P: 0.02%, S: 0.012%, Ti: 0.02%, B: 0.03%, Al: 0.04% and the remainder: Fe and impurities) were used to form Al plating layers on both sides by Sen's strip nitriding dip galvanizing method. The annealing temperature was set at about 800° C., and the Al plating bath contained 9% by mass of Si and Fe eluted from the cold-rolled steel sheet. The deposition amount (weight per unit area) of the Al plating layer after plating is adjusted by the gas wiping method, and the deposition amount (weight per unit area) of the Al coating layer formed on both sides (upper surface and lower surface) of the cold-rolled steel sheet is set as 40g / m 2 Afte...

Embodiment A-

[0295] "Manufacturing of punching dies"

[0296] ·Base material

[0297] Prepare steels of the materials listed in Table 1, rough machine them in the annealed state, and Figure 8 The approximate shape of the upper mold 102A and the lower mold 102B shown in , is maintained by heating at 1180°C in vacuum, quenched by nitrogen cooling, and quenched and tempered to 64HRC by tempering at 540-580°C. After that, finish machining is performed to obtain the base material of the die.

[0298] ・Formation of nitride layer

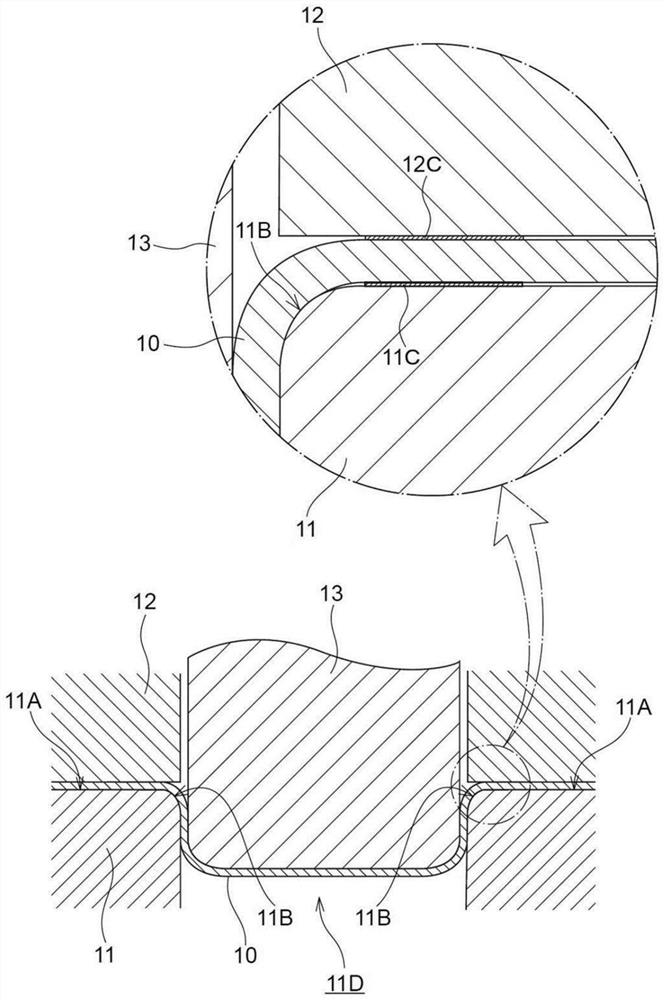

[0299] Next, a nitride layer was formed on the steel plate contact surfaces of the upper mold 102A and the lower mold 102B that contact (slide) the plated steel sheet 10 .

[0300] The above base material was subjected to ion nitriding treatment under the conditions shown below. That is, with a flow ratio of 5% N 2 (remainder is H 2 ) in an atmosphere of 500° C. for 5 hours to perform ion nitriding treatment, and then finish machining by polishing each test surf...

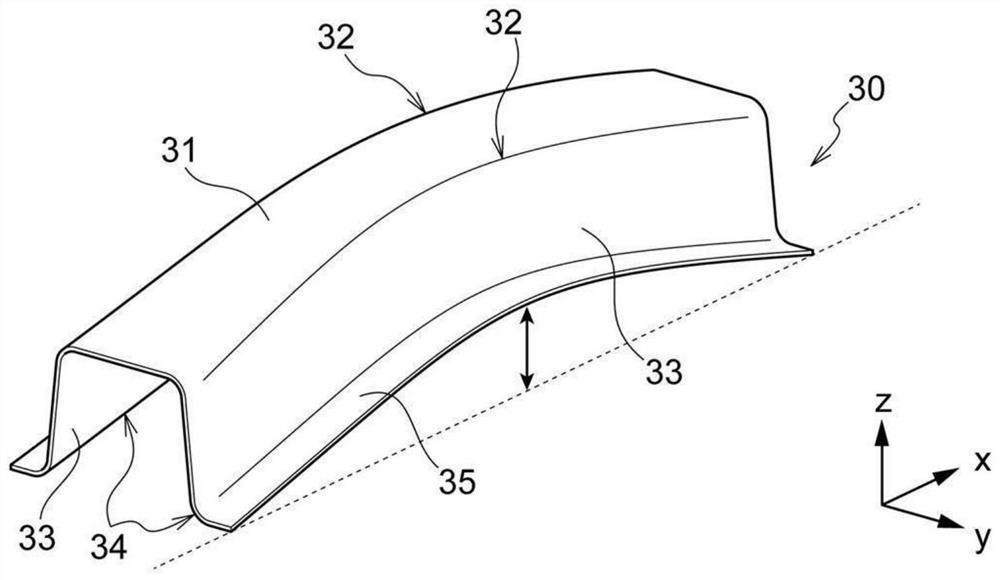

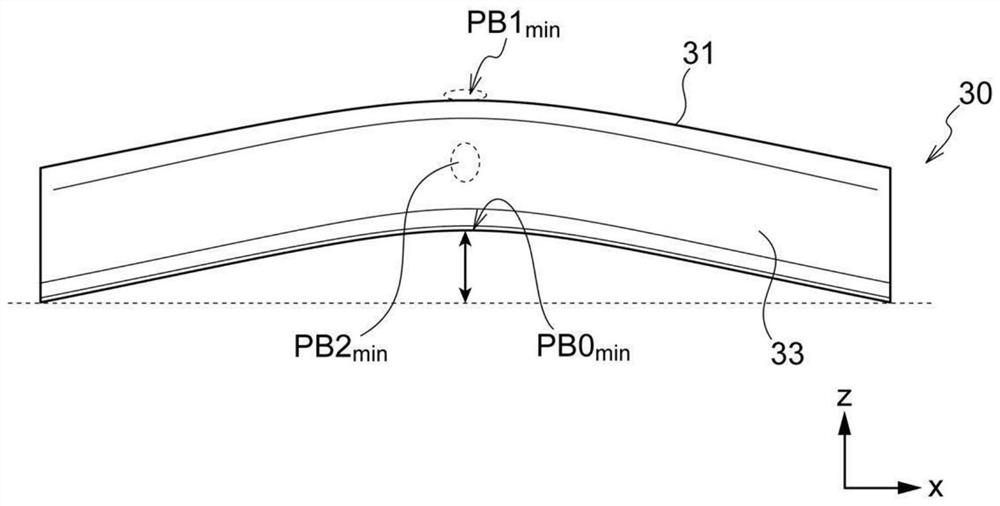

Embodiment 1

[0304] According to the method described in the above-mentioned "making of punch die", the composition of the PVD film is set to the composition described in the following Table 2, and the hardness of the PVD film is adjusted so as to become the value described in the following Table 2, Die dies (upper die 102A and lower die 102B) were produced.

[0305] The deflection (Rsk) in the sliding direction of the plated steel sheet 10 in contact (sliding) was measured by the method described above for the steel sheet contact surface of the obtained die. Moreover, the hardness Hv_Die was measured by the method mentioned above about the steel plate contact surface of the obtained die|die.

[0306] Using the plated steel sheets and dies shown in Table 2, evaluations described below were implemented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com