Peeling device and peeling method of substrate, and manufacturing method of electronic device

A technology for peeling off devices and substrates, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

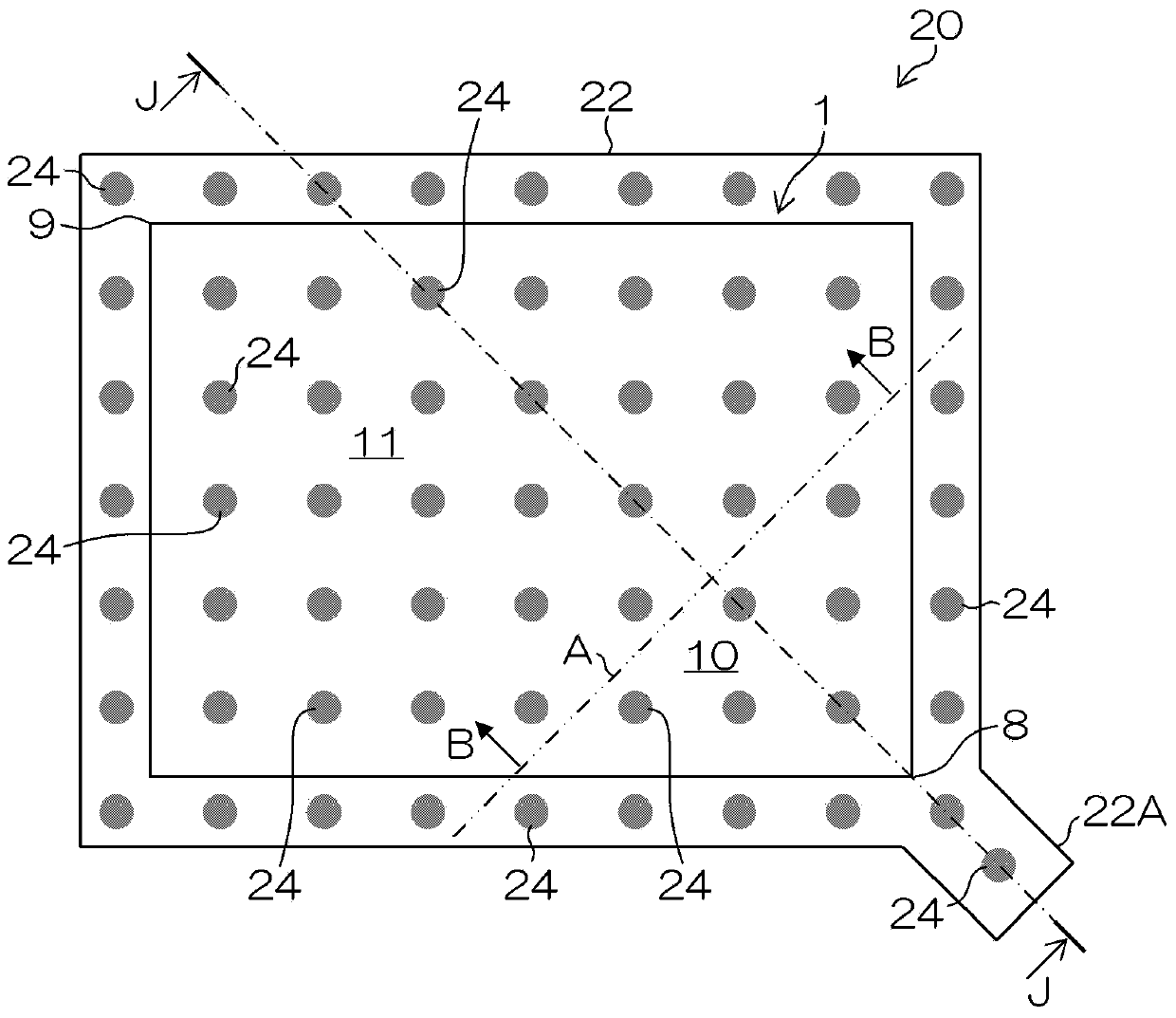

[0044] Hereinafter, embodiments of a substrate peeling device, a peeling method, and an electronic device manufacturing method according to the present invention will be described with reference to the drawings.

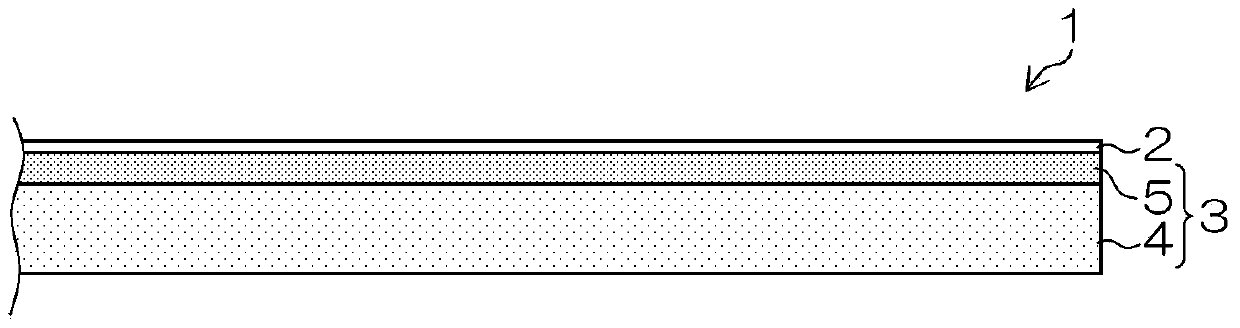

[0045] figure 1 It is an enlarged side view of main parts of the laminated board 1 used in the manufacturing process of an electronic device.

[0046] (Manufacturing method of electronic device)

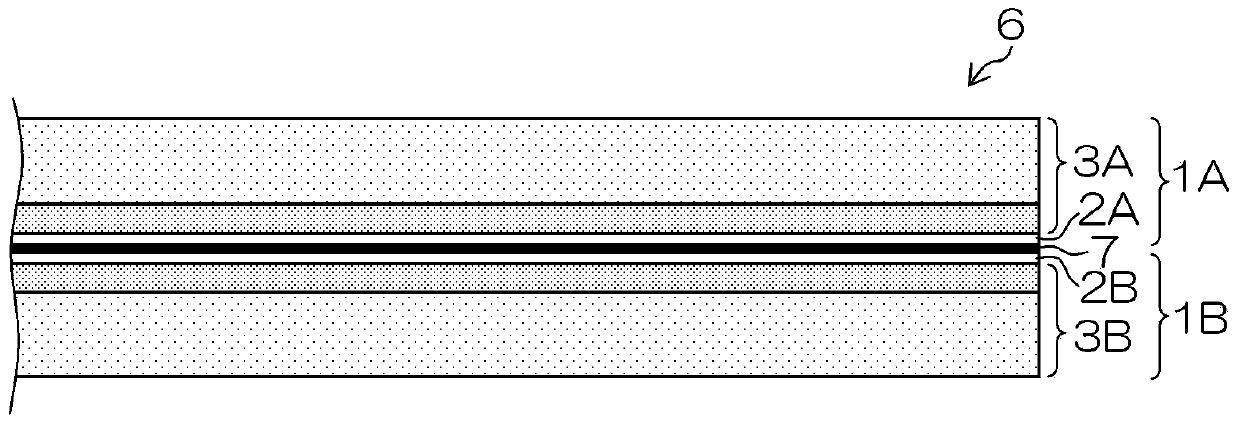

[0047] In order to cope with the thinning of the substrate 2 used in electronic devices, the manufacturing method of the electronic device according to the embodiment has the following steps: constructing the laminated board 1 in which the front surface of the reinforcing plate 3 is pasted on the back surface of the substrate 2, and forming a laminated board 1 on the laminated board 1 A functional layer forming step of forming a functional layer on the surface of the substrate 2 ; and a peeling step of peeling between the substrate 2 on which the functional layer is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com