Motor, rotor and method for manufacturing rotor

一种电动机、转子的技术,应用在电动组件、制造定子/转子本体、机电装置等方向,能够解决电动机大型化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

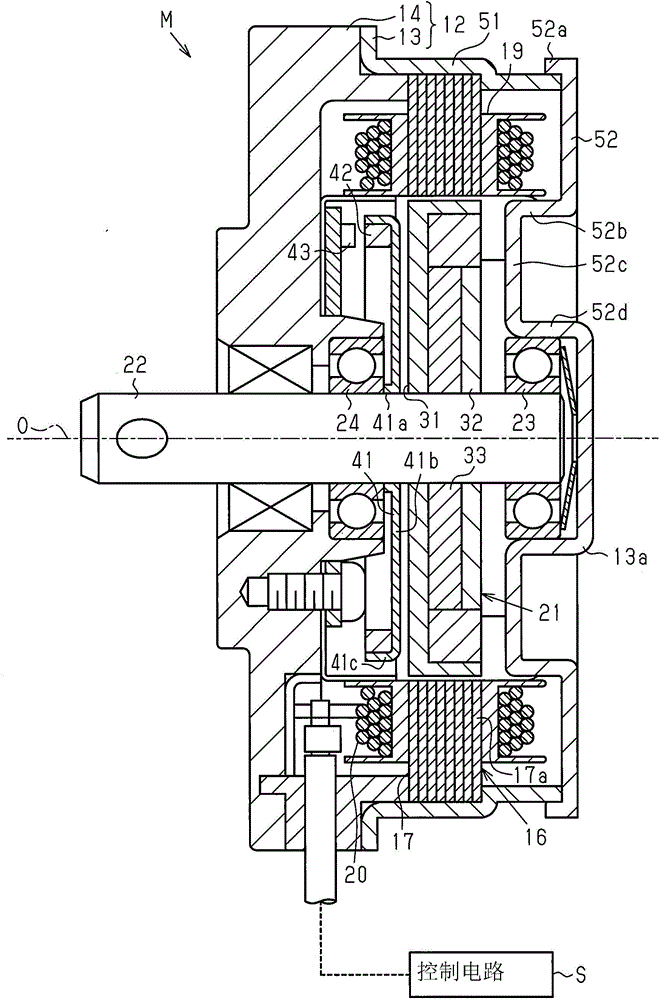

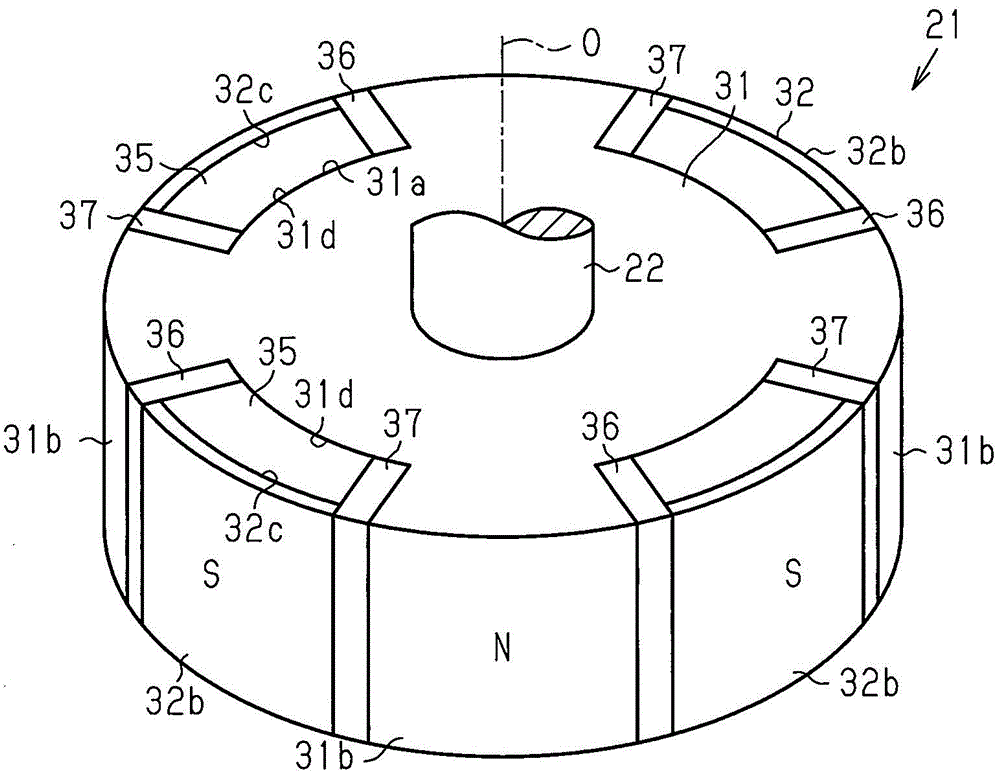

[0031] below, according to Figure 1 to Figure 4 A first embodiment of the motor will be described.

[0032] Such as figure 1 As shown, the housing 12 of the brushless motor M as a motor has: a yoke case 13 formed in a substantially bottomed cylindrical shape; Closed, the end plate 14 is made of a resin material which is a non-magnetic body.

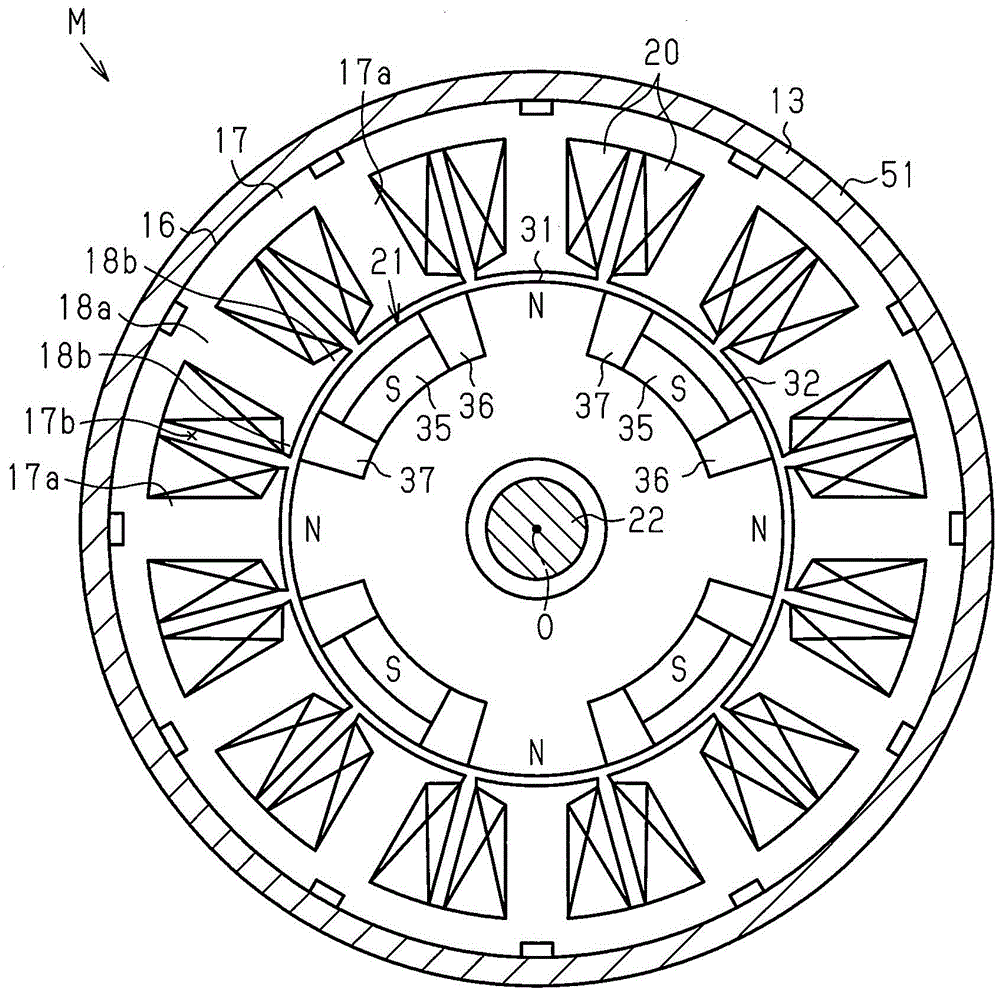

[0033] Such as figure 1 As shown, the stator 16 is fixed to the inner peripheral surface of the yoke housing 13 . The stator 16 includes: a stator core 17 having a plurality of teeth 17 a extending radially inward; and a coil 20 wound around the teeth 17 a of the stator core 17 via an insulator 19 . The stator 16 generates a rotating magnetic field by supplying a driving current from an external control circuit S to the winding 20 .

[0034] Such as figure 2 As shown, the stator core 17 of the first embodiment has twelve teeth 17 a in the circumferential direction. Therefore, the number of tooth spaces 17b formed between each too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com