An operation and maintenance automation system and method

A technology of automation system and operation and maintenance system, applied in the direction of transmission system, digital transmission system, electrical components, etc., can solve the problems of increased workload, non-centralized management, and failure to integrate various resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

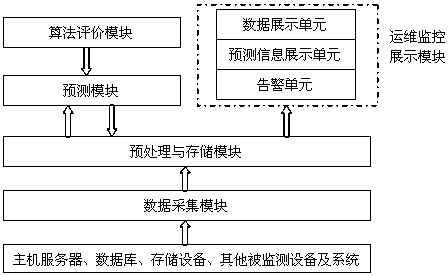

[0095] Describe technical scheme of the present invention in further detail below in conjunction with accompanying drawing: as figure 1 As shown, an operation and maintenance automation system includes:

[0096] Data acquisition module: used to obtain the key performance indicators and operating status of each monitored unit in the operation and maintenance system through network management protocols or log files, and provide data basis for operation and maintenance data processing, analysis and prediction;

[0097] In the operation and maintenance system, the data required for operation and maintenance monitoring mainly come from host servers, databases, storage devices, application systems and other related network devices and systems in the cluster. Data collection is to obtain the KPI (key performance indicators) and operating status information of each monitored unit in the operation and maintenance system through a certain network management protocol (Syslog, SNMP, Telnet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com