Two-side grinding mechanism for glass

A double-sided grinding and glass technology, applied in machine tools suitable for grinding workpiece edges, grinding machine parts, grinding feed motion, etc. , the effect of high versatility and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

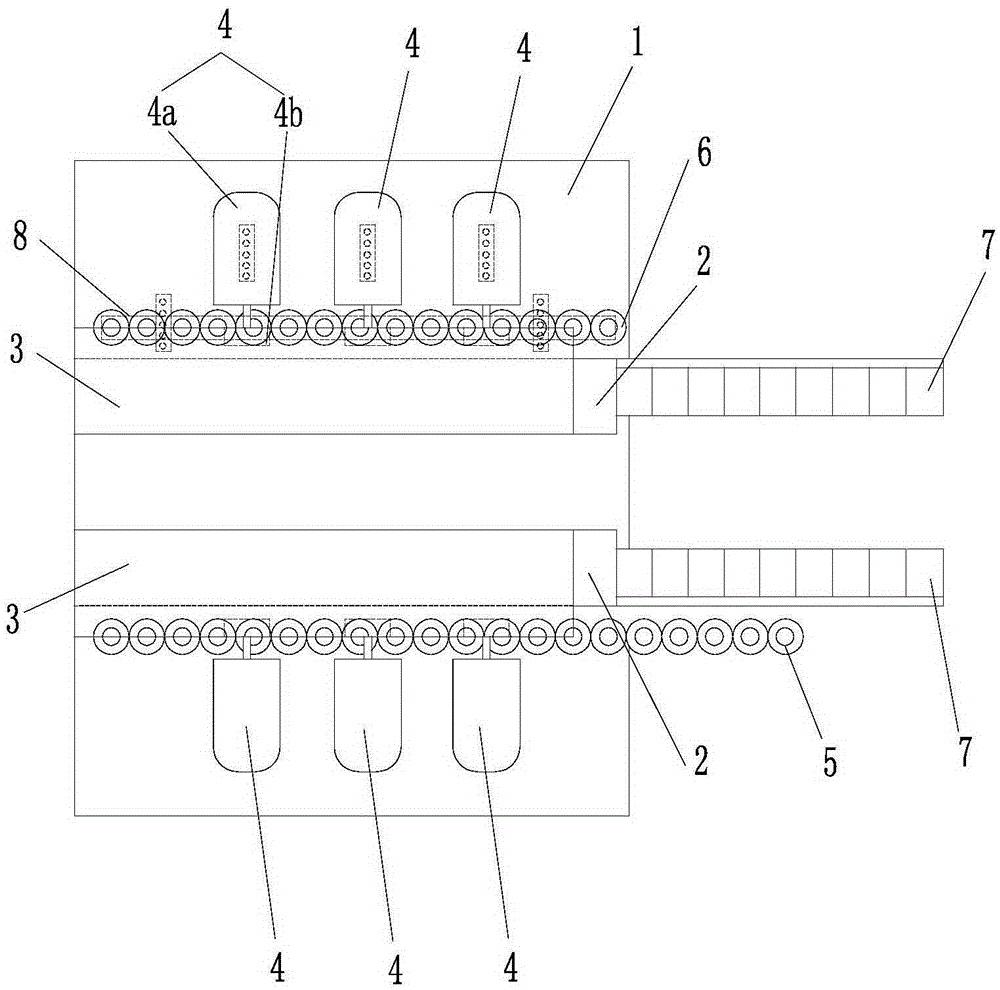

[0010] like figure 1 The shown double-sided grinding mechanism for glass mainly consists of a base 1, two automatic conveyor belts 2, two pressing frames 3, several groups of grinding heads 4, a row of fixed guide wheels 5, a row of moving guide wheels 6, Two rows of rubber conveying rollers 7 and guide wheel brackets 8 are formed.

[0011] There are two parallel automatic conveyor belts 2 arranged at left and right intervals on the base 1, and a compression frame 3 is arranged above each automatic conveyor belt 2, and the distance between the compression frame 3 and the automatic conveyor belt 2 is just in line with the The thickness of the glass is matched, and the glass passes through the gap between the compression frame 3 and the automatic conveyor belt 2 under the action of the automatic conveyor belt 2. The compression frame 3 exerts a certain pressure on the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com