A kind of polyester elastomer and its preparation method and toughening agent

A polyester elastomer and prepolymer technology, applied in the field of elastomers, can solve the problems of restricting the application of polyester elastomers and poor toughening performance, and achieve the effects of good toughening performance and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of polyester elastomer, comprising:

[0038] Under the action of catalyst and chain extender, react adipic acid and glycol to obtain polyester elastomer;

[0039] The catalyst includes one or more of acetate, tin compound, titanium compound and antimony compound;

[0040] The chain extender includes hydroxyl compounds or isocyanate compounds.

[0041] The invention reacts adipic acid and glycol under the action of catalyst and chain extender to obtain polyester elastomer. In an embodiment of the present invention, the preparation method of the polyester elastomer is:

[0042] Adipic acid and dihydric alcohol are subjected to an esterification reaction to obtain an intermediate product;

[0043] Under the action of a catalyst, the intermediate product is subjected to a polymerization reaction to obtain a prepolymer;

[0044] Under the action of a chain extender, the prepolymer is chain extended to obtain a polyester...

Embodiment 1

[0064] Under the protection of nitrogen, 1023g of adipic acid and 742g of diethylene glycol were added to the reactor, and the oil bath was heated to 210°C with stirring for 6 hours of esterification reaction. During the esterification reaction, the generated water Continue to distill off to obtain a light-colored intermediate product;

[0065] Add 6.2 g of tetrabutyl titanate to the above-mentioned intermediate product and raise the temperature to 220° C. for 5 hours of polymerization under the condition of 60 Pa to obtain a prepolymer, which is a light yellow transparent viscous liquid;

[0066] Add 27 g of trimethylolpropane to the prepolymer and raise the temperature to 260° C. and stir for 10 hours to carry out chain extension to obtain a slightly yellow and transparent polyester elastomer.

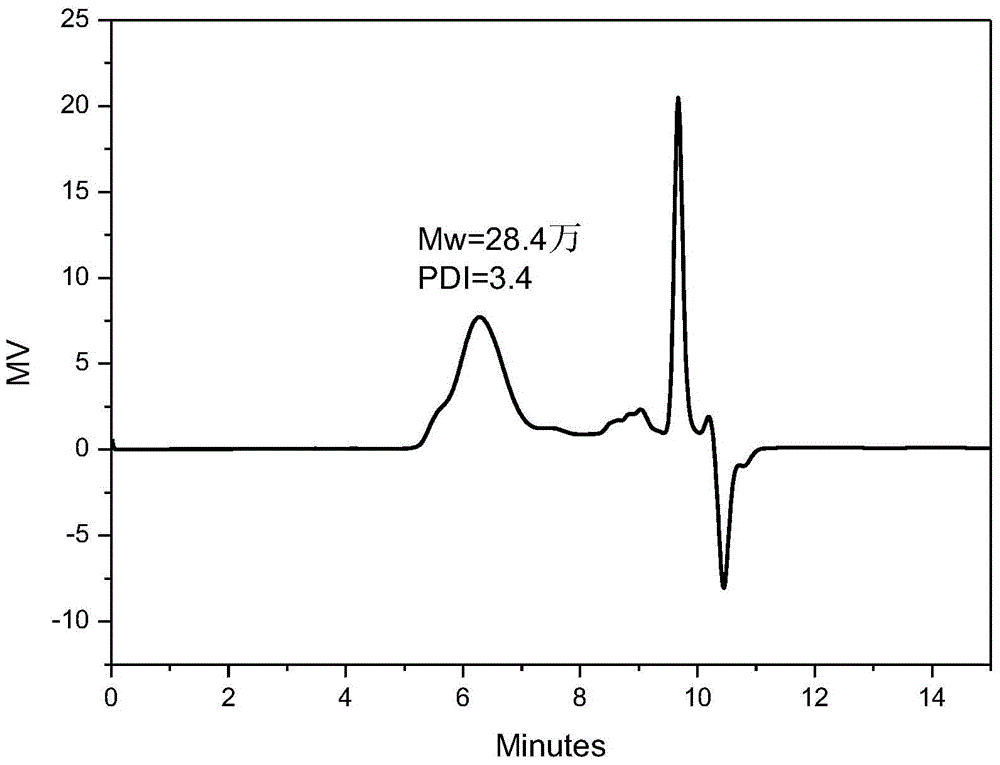

[0067] The polyester elastomer prepared in Example 1 of the present invention is subjected to gel permeation chromatography test, and the test results are as follows: figure 1 as sh...

Embodiment 2

[0070] Under the protection of nitrogen, 1023g of adipic acid and 845g of diethylene glycol were added to the reactor, and the oil bath was heated to 185°C with stirring for 6 hours of esterification reaction. During the esterification reaction, the generated water Continue to distill off to obtain a light-colored intermediate product;

[0071] Add 6.2 g of tetraisopropyl titanate to the above-mentioned intermediate product and raise the temperature to 220° C. for 8 hours of polymerization under the condition of 60 Pa to obtain a prepolymer, which is a light yellow transparent viscous liquid;

[0072] Add 30 g of 4,4'-methylene bis(phenyl isocyanate) (MDI) to the prepolymer and stir at 70°C for 10 hours for chain extension to obtain a yellow transparent polyester elastomer.

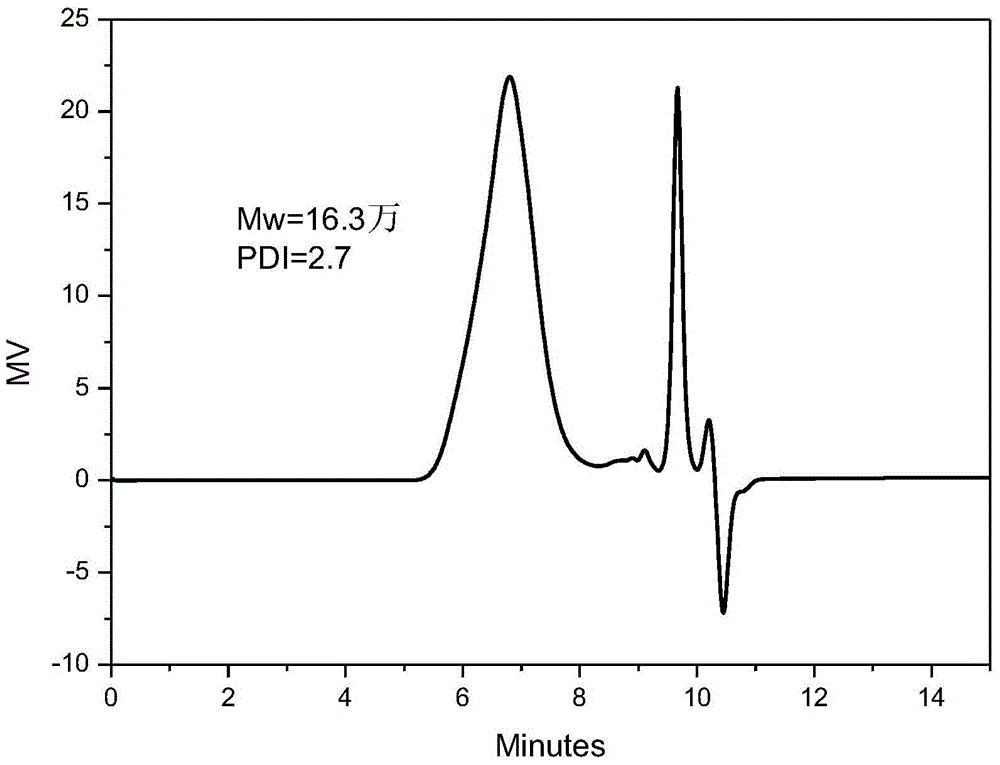

[0073] The polyester elastomer prepared in Example 2 of the present invention is subjected to gel permeation chromatography test, and the test results are as follows: image 3 as shown, image 3 For the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com