An edge-driven top-blown converter

A top-blown converter and edge technology, which is applied in the field of smelting furnaces, can solve the problems that the furnace body cannot be overturned, the equipment cannot be produced normally, and the adjustment takes a long time, so as to improve safety and work stability, and save equipment investment. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

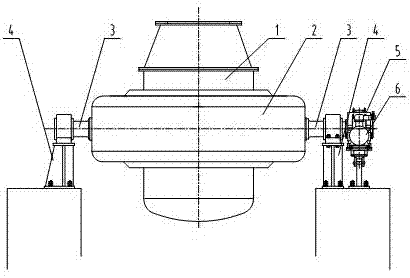

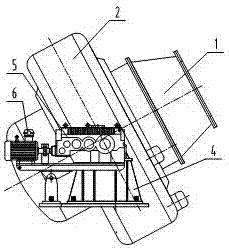

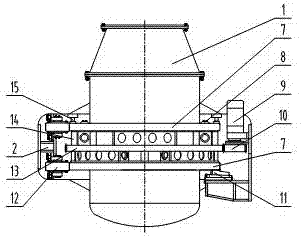

[0026] An edge-driven top-blown converter includes a furnace body 1 and a rotary power source 9 respectively placed on a frame 2 .

[0027] The frame 2 is provided with an axial supporting wheel 11 and a top column 15 along the axial direction, and a radial supporting wheel 12 is provided along the radial direction, and is flexibly connected with a furnace body bracket ring 14; Rolling rings 7 are provided on the upper and lower ring surfaces, and a ring gear 13 is provided in the middle, and a gear 10 is meshed at one end of the ring gear 13; the gear 10 is connected to the rotary power source 9; the tilting support shaft 3 is provided in the frame 2, Both ends of the tilting support shaft 3 are respectively fixed on the equipment foundation through a support 4 , and one end thereof is connected with a tilting reducer 5 with a tilting power source 6 .

[0028] Wherein: the furnace body 1 is flexibly connected to the furnace body bracket ring 14 through the elastic element 8 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com