Double-gear type wiggler with clearance eliminating function

An oscillator and gear-type technology, applied in the field of oscillators, can solve the problems that the swing fails to meet the requirements, the swing head shakes, and the repair effect of the automatic welding robot on the water cooling wall is affected, so as to improve the repair effect and avoid head swing. shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

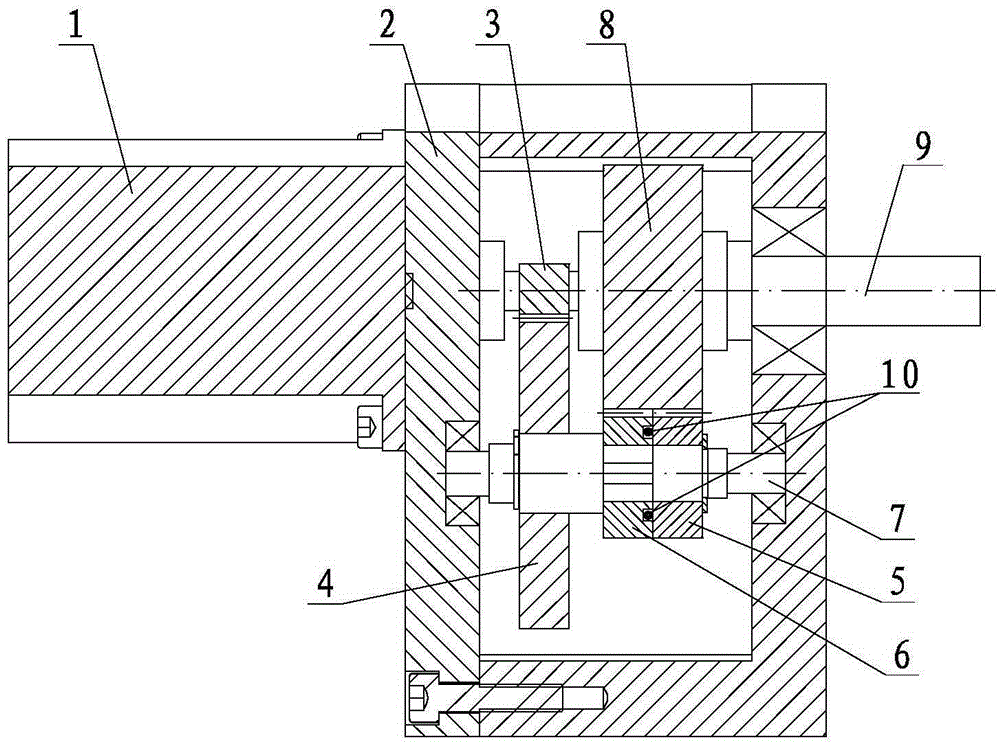

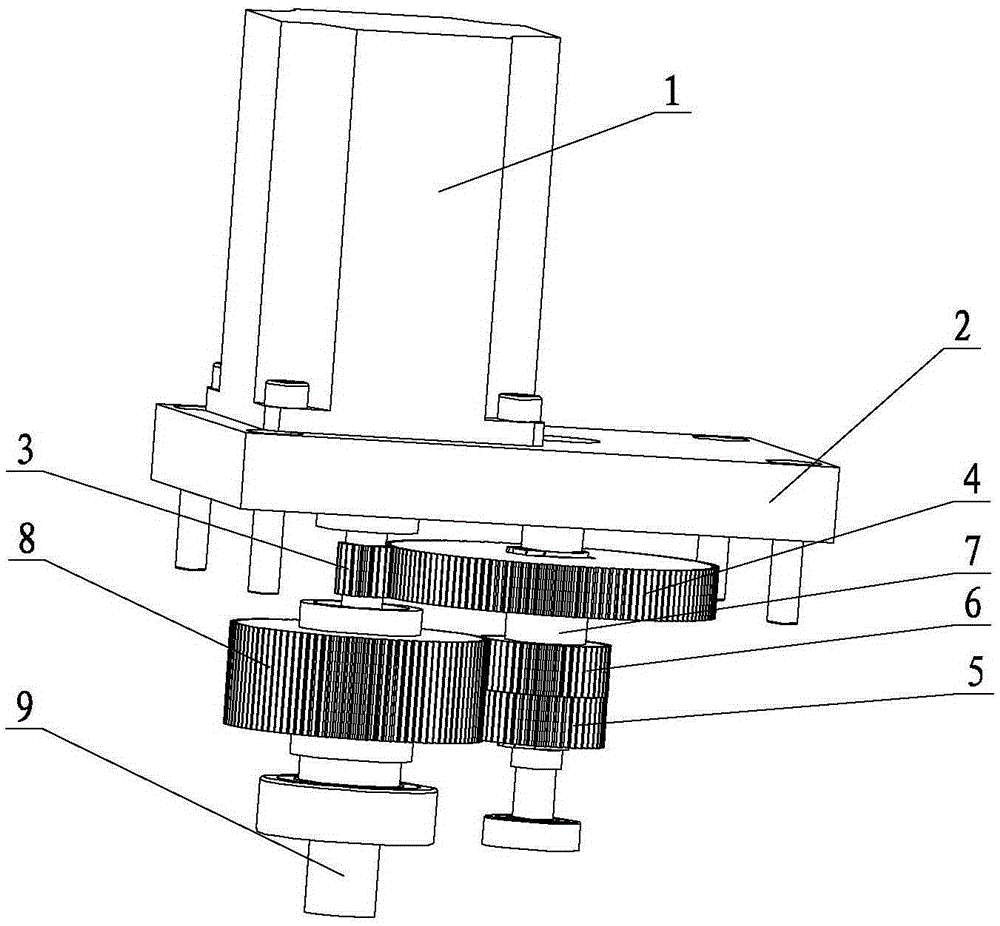

[0012] Specific implementation mode 1: Combination Figure 1 ~ Figure 4 To describe this embodiment, this embodiment includes a motor 1, a housing 2, a primary reduction pinion 3, a primary reduction gear 4, a driving gear 5, an anti-backlash gear 6, a transmission shaft 7, a driven gear 8, and a driven Shaft 9, driven shaft 10, several springs 10 and several pressure blocks 11, the motor 1 is fixed outside the housing 2, and the primary reduction pinion 3 is arranged in the housing 2 and fixed to the output shaft of the motor 1. Above, the primary reduction gear 4 meshes with the primary reduction pinion 3, the primary reduction gear 4, the anti-backlash gear 6 and the driving gear 5 are arranged on the transmission shaft 7 in sequence, the primary reduction gear 4 and the driving gear 5 It is fixedly mounted with the transmission shaft 7, the anti-backlash gear 6 and the transmission shaft 7 are in clearance fit, the driving gear 5 is in contact with the anti-backlash gear 6,...

specific Embodiment approach 2

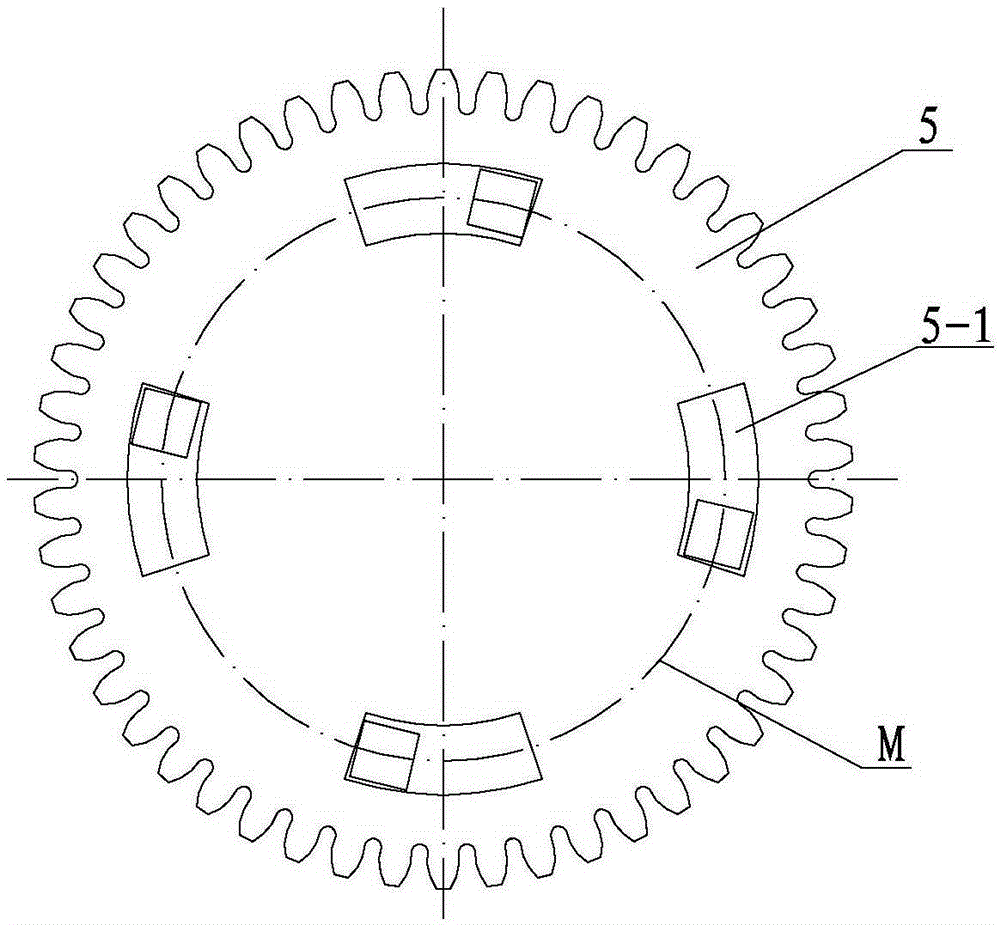

[0013] Specific implementation manner two: combination image 3 with Figure 4 To describe this embodiment, the numbers of the spring 10, the pressure block 11, and the arc-shaped long groove 5-1 in this embodiment are all 2 to 5. When the spring 10 is within the above numerical range, the spring 10 can hold the anti-backlash gear 6 so that the anti-backlash gear 6 rotates with the driving gear 5 while compensating the gap between the driving gear 5 and the driven gear 8, thereby eliminating the driving The gear 5 and the driven gear 8 mesh with a gap. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination image 3 with Figure 4 To describe this embodiment, the numbers of the spring 10, the pressure block 11, and the arc-shaped long groove 5-1 in this embodiment are all four. The four springs 10 are the best values. The anti-backlash gear 6 is held by the spring 10 so that the anti-backlash gear 6 rotates with the driving gear 5 while compensating for the gap between the driving gear 5 and the driven gear 8, thereby eliminating the driving The gear 5 and the driven gear 8 mesh with a gap. Other components and connection relationships are the same as in the second embodiment.

[0015] Working principle: see Figure 5 , The motor 1 drives the primary reduction pinion 3 to rotate, the primary reduction gear 4 rotates and drives the driving gear 5 to rotate, the driving gear 5 and the anti-backlash gear 6 mesh with the driven gear 8 at the same time, and the adjacent ones on the driven gear 8 There is a tooth on the driving gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com