Industrial Process Fault Detection Method Based on Supervised Linear Dynamic System Model

A dynamic system model and industrial process technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of using quality variables and ignoring important information of the quality variable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

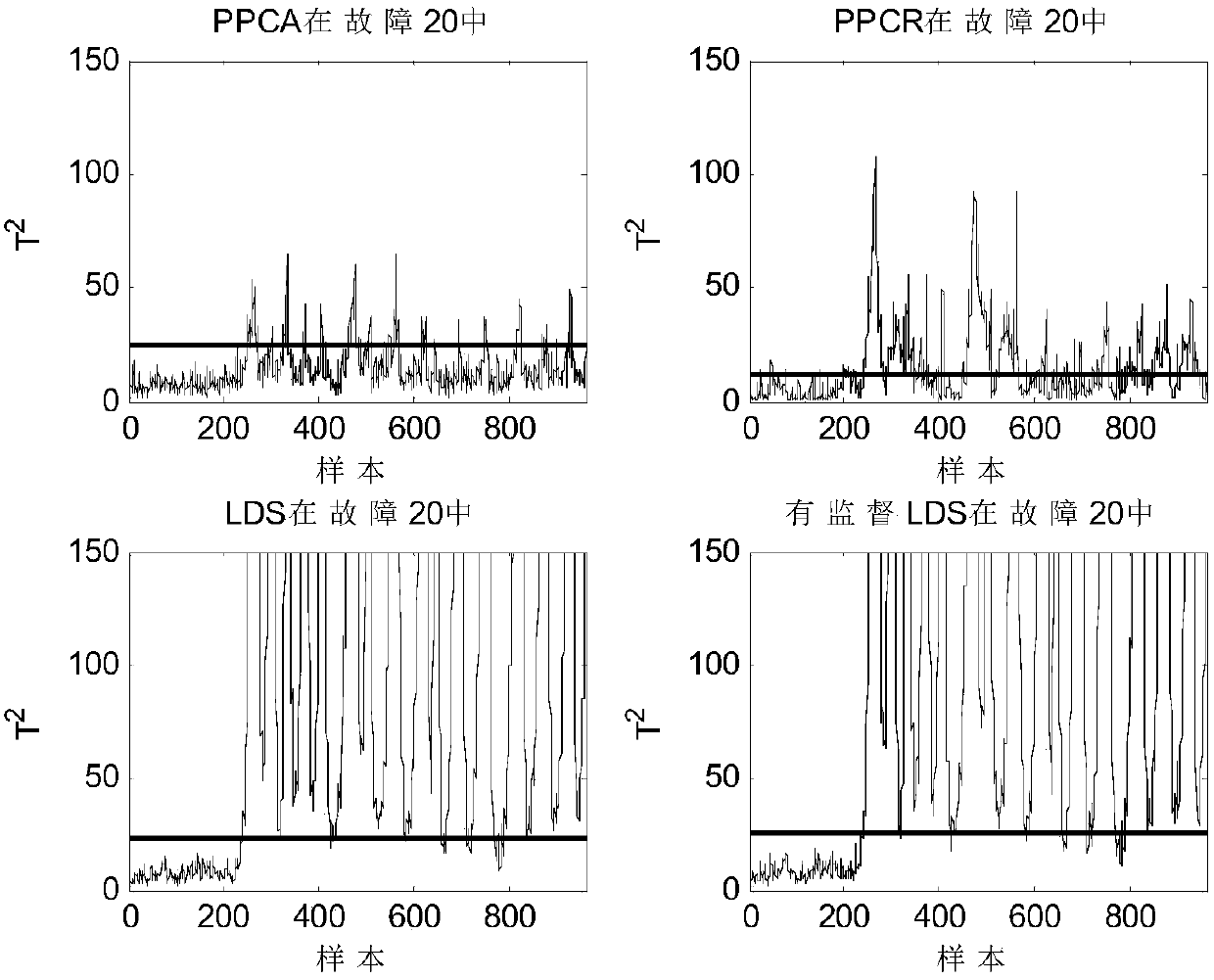

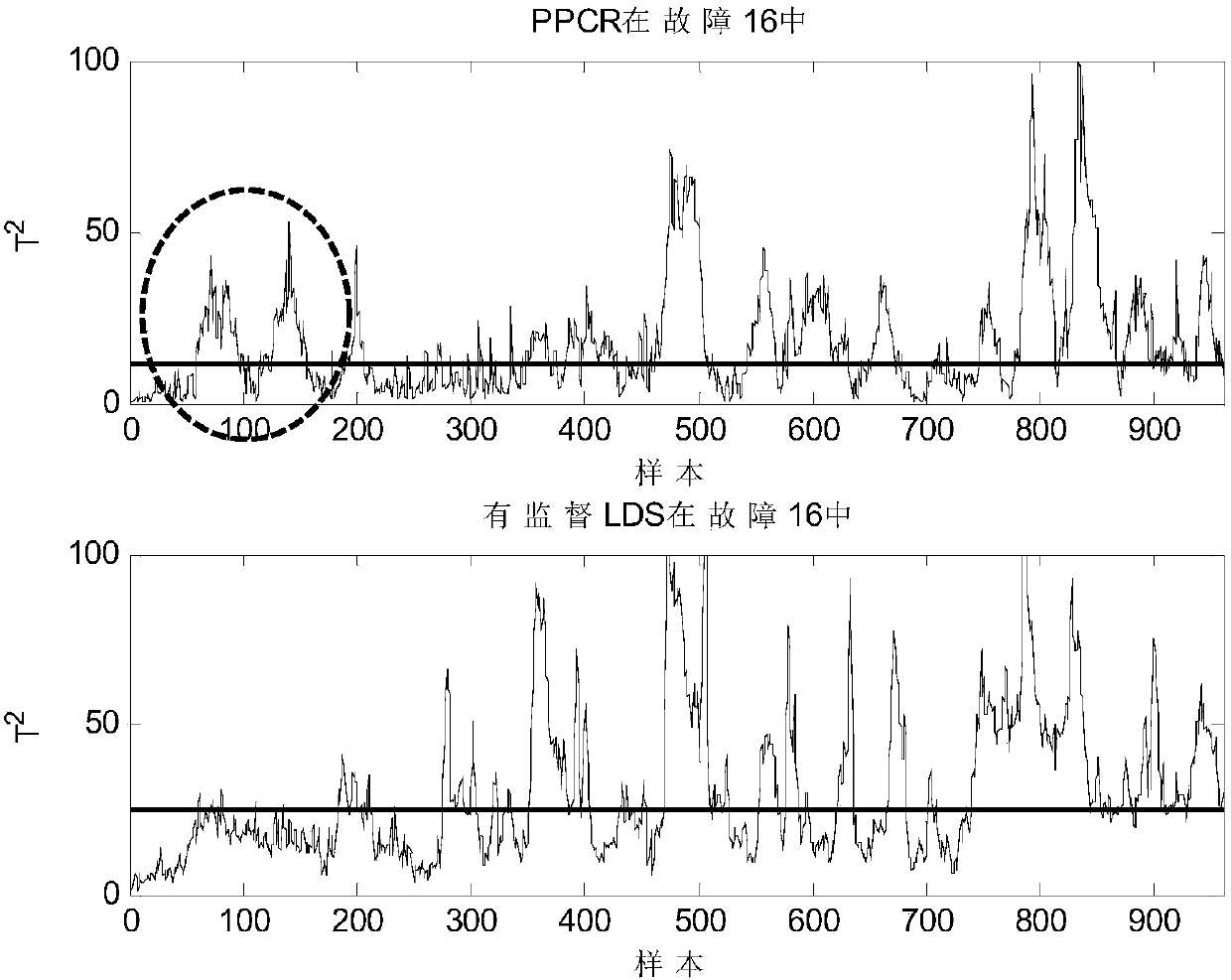

[0051] The invention discloses an industrial process fault detection method based on a supervised linear dynamic system model. The method aims at the fault detection problem of the industrial process. Firstly, a distributed control system is used to collect process variable data and quality variable data, and standardize them deal with. Then a supervised linear dynamic system model is established, and the model parameters are stored in the database for future use. Finally build T for the new online data 2 Statistics, compared with statistical limits to obtain fault detection results.

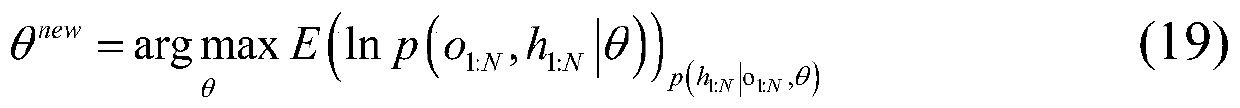

[0052] The main steps of the technical solution adopted in the present invention are as follows:

[0053] The first step: use the collection and distribution system to collect data of process variables to form a training sample set of process var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com