A tire X-ray image detection and recognition method and system

A recognition method and optical image technology, applied in the field of image recognition, can solve the problems of heavy workload and poor versatility of workers, and achieve the effects of unified judgment standards, high accuracy and improved judgment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

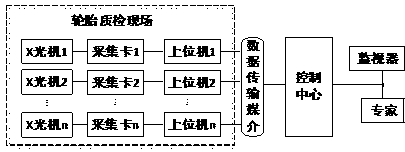

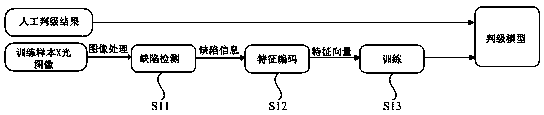

[0048] Embodiment one, see figure 1 , figure 2 As shown, the present embodiment proposes a tire X-ray image detection and recognition method, including an offline training step and an online detection step, and the offline training step includes the following sub-steps:

[0049] S11. Establish a training sample, including a number of tire X-ray images and corresponding judgment results;

[0050] S12. Perform defect detection on images in the training samples, and calculate defect information of the training samples;

[0051] S13. Quantify and encode the training sample defect information into a training sample feature vector to form an n-dimensional vector, and the parameters n represent n types of defects respectively;

[0052] S14. Using the classification result of the image in the training sample as a sample label, train the feature vector of the training sample into a classification model;

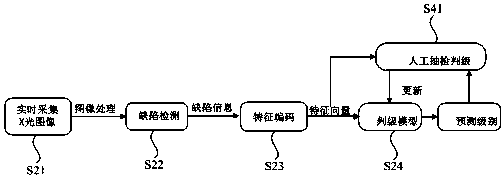

[0053] The online detection step includes the following sub-steps:

[0054] ...

Embodiment 2

[0060] Embodiment 2, in step S13, the judgment model in this embodiment preferably adopts an incremental extreme random forest classifier. Random forest is a classifier that contains multiple decision trees, in which the construction and classification test of each decision tree are independent of each other, and the classifier output is the mode of all decision tree outputs.

[0061] In the offline training step, the traditional method is used to detect defects in the tire X-ray images in the training samples, and calculate defect information, such as the size of impurities, the number of broken ends of steel cords, etc. The defect information is quantized and encoded into a feature vector, and different types of defect information are stored in different dimensions. Using the result of manual classification as the true value of the category, the tire X-ray image training samples are used to train a linear or nonlinear classification model to characterize the mapping relation...

Embodiment 3

[0077] Embodiment 3, based on the tire X-ray image detection and recognition methods in Embodiment 1 and Embodiment 2, this embodiment provides a tire X-ray image detection and recognition system, including an offline training subsystem and an online detection subsystem. The offline training subsystem includes at least a database and a training unit storing training samples, and the training unit is used for:

[0078] Perform defect detection on the images in the training samples, and calculate the defect information of the training samples;

[0079] The training sample defect information is quantized and encoded as a training sample feature vector to form an n-dimensional vector, said

[0080] The parameter n represents n types of defects respectively;

[0081] Using the classification result of the image in the training sample as a sample label, training the training sample feature vector into a classification model;

[0082] The online detection subsystem includes:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com