Square battery packaging machine

A square battery and packaging machine technology, which is applied in battery assembly machines, primary batteries, secondary battery manufacturing, etc., can solve the problems of lower product yield, lower production efficiency, and unstandardized products, so as to improve yield and increase production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

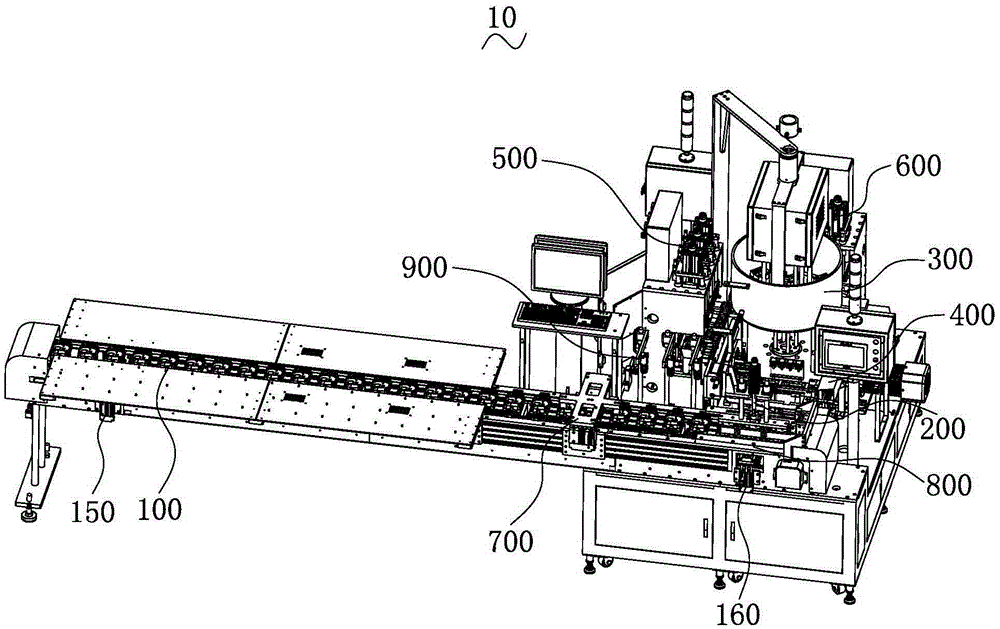

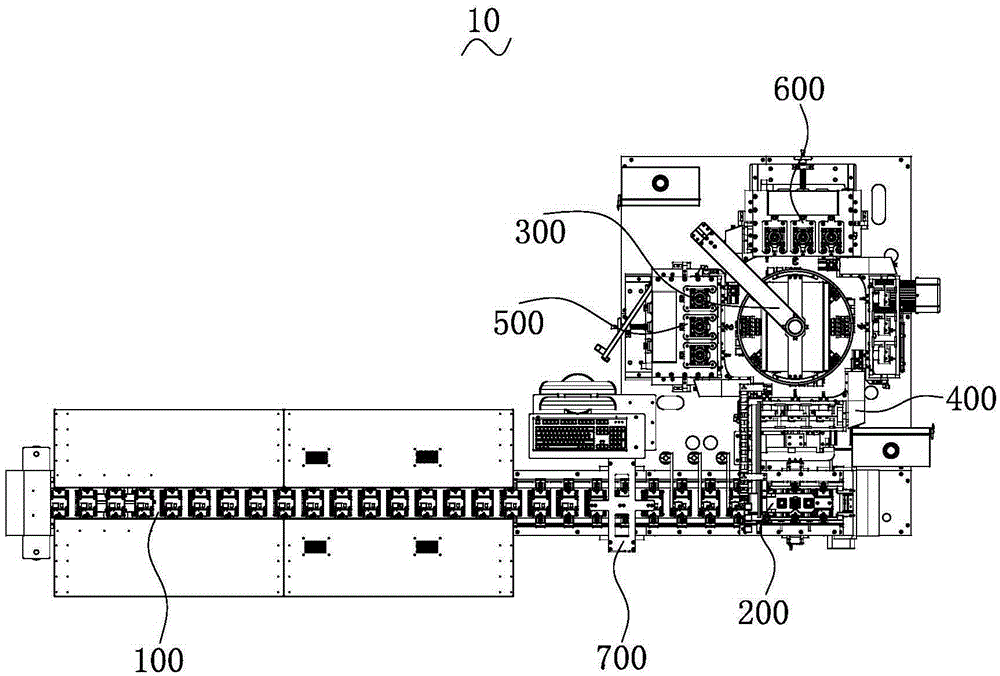

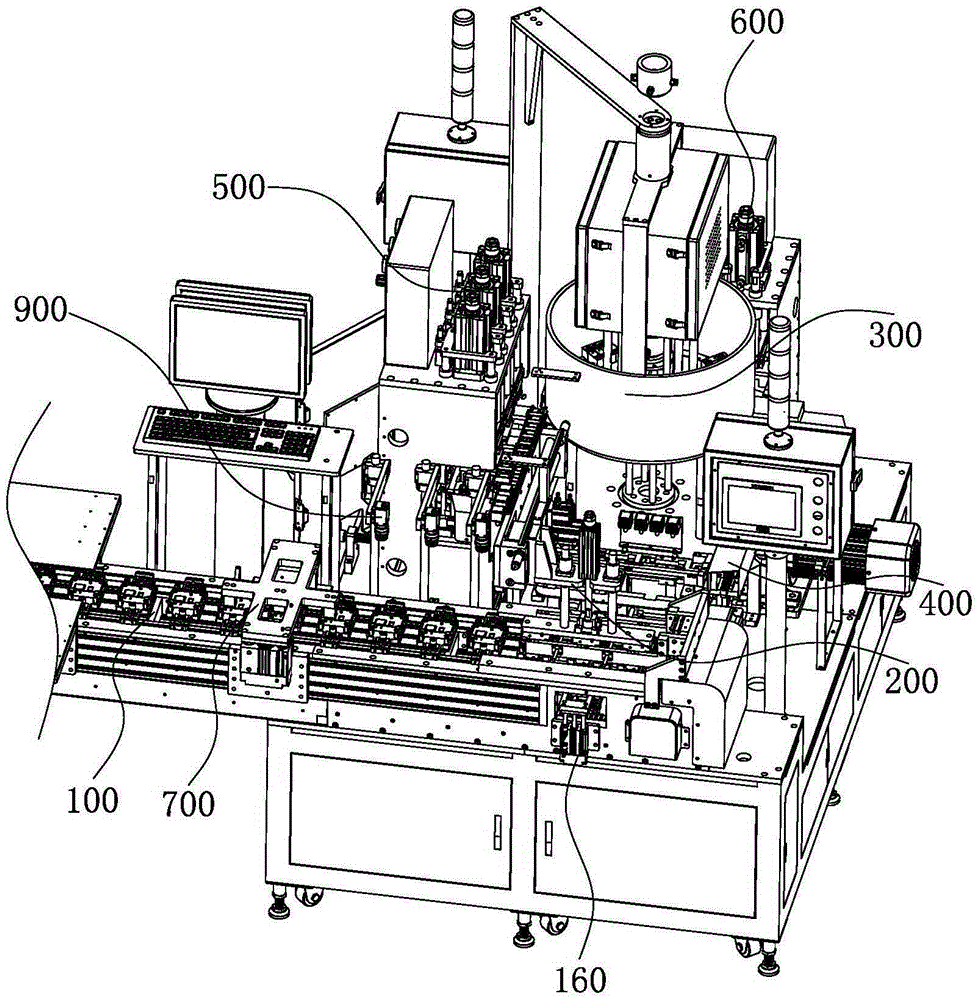

[0037] Such as figure 1 and figure 2 As shown, they are respectively a perspective view and a top view of the prismatic battery packaging machine 10 . Please also refer to image 3 , which is a partial structural diagram of the prismatic battery packaging machine 10 .

[0038] The square battery packaging machine 10 includes: a feeding line 100, a feeding manipulator 200, a turntable 300, a folding device 400, a top sealing device 500, and a side sealing device 600. The feeding manipulator 200 is connected between the feeding line 100 and the turntable 300, The folding device 400 , the top sealing device 500 and the side sealing device 600 are arranged around the turntable 300 .

[0039] The feeding line 100 is used to transport the aluminum-plastic film and the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com