electrical connector

A technology of electrical connectors and soldering pins, applied in the direction of connection, fixed connection, circuit, etc., can solve problems such as poor tin coating and inability to repair, and achieve the effect of ensuring electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

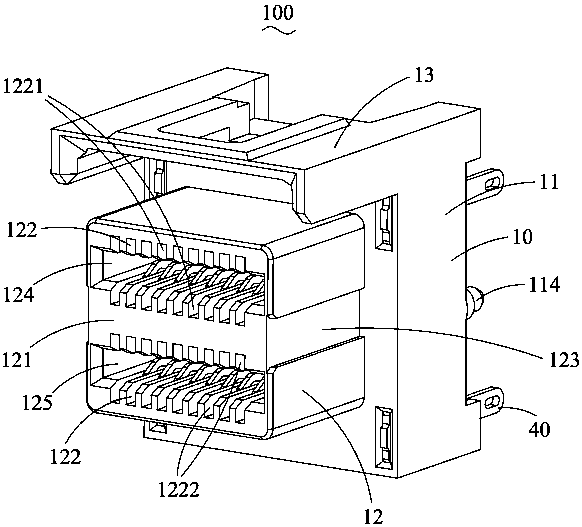

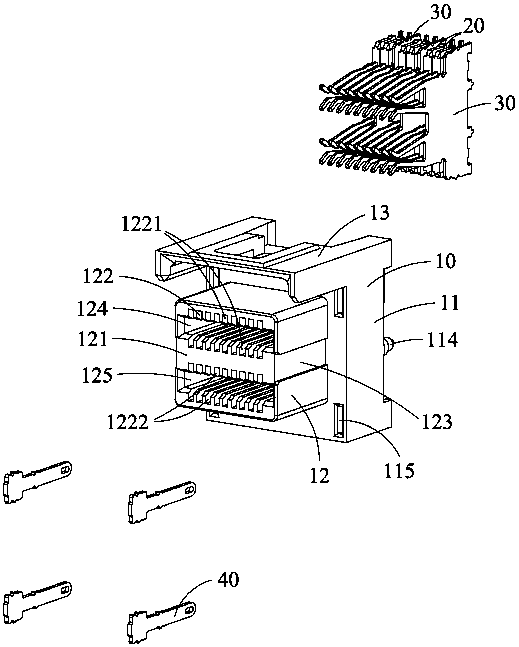

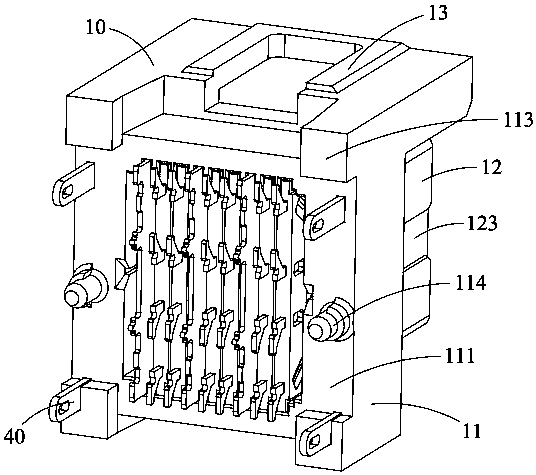

[0026] see figure 1 as well as figure 2 As shown, the illustrated embodiment of the present invention discloses a high-frequency electrical connector 100 , which is used to be welded on a circuit board (not shown) to connect with a mating electrical connector (not shown). The electrical connector 100 includes an insulating body 10, a plurality of signal terminal pairs 20 accommodated in the insulating body 10, a plurality of grounding terminals 30 accommodated in the insulating body 10, and a device mounted on the insulating body 10. 40 slices. The pairs of signal terminals 20 are arranged side by side along the transverse direction of the electrical connector 100 , and the ground terminals 30 are located between adjacent pairs of signal terminals 20 along the transverse direction of the electrical connector 100 .

[0027] see figure 1 , figure 2 , image 3 as well as Figure 4 As shown, the insulating housing 10 includes a main body 11 , a docking portion 12 protrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com