Rotolinear clamping cylinder

A clamping cylinder, clamping position technology for clamping, climate sustainability, final product manufacturing, etc., that can solve problems that hinder automatic operation, cannot ensure stack retention, cannot detect clamping position or release position, etc. , to achieve the effect of increasing service life, reducing price and weight, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

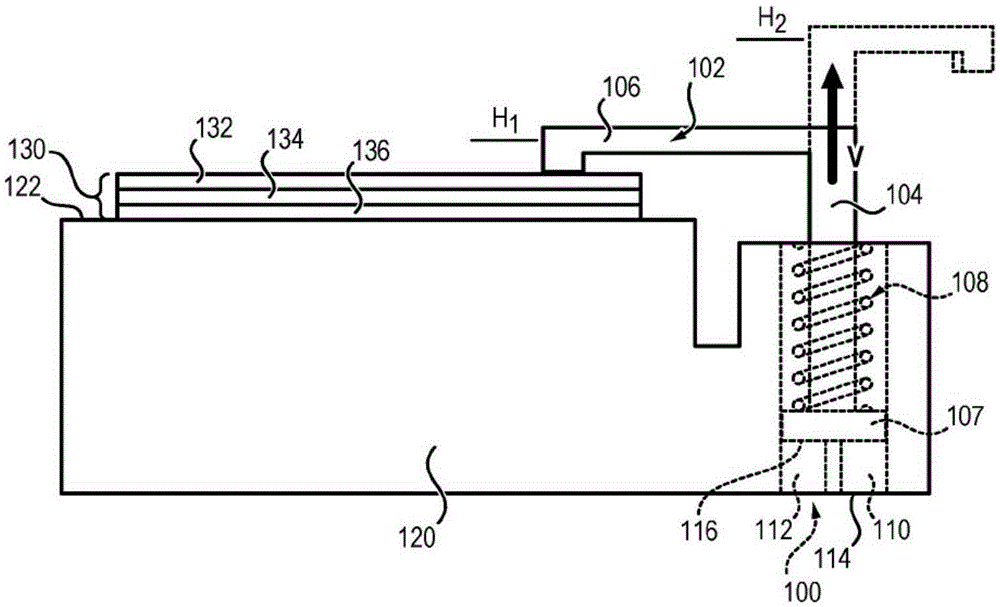

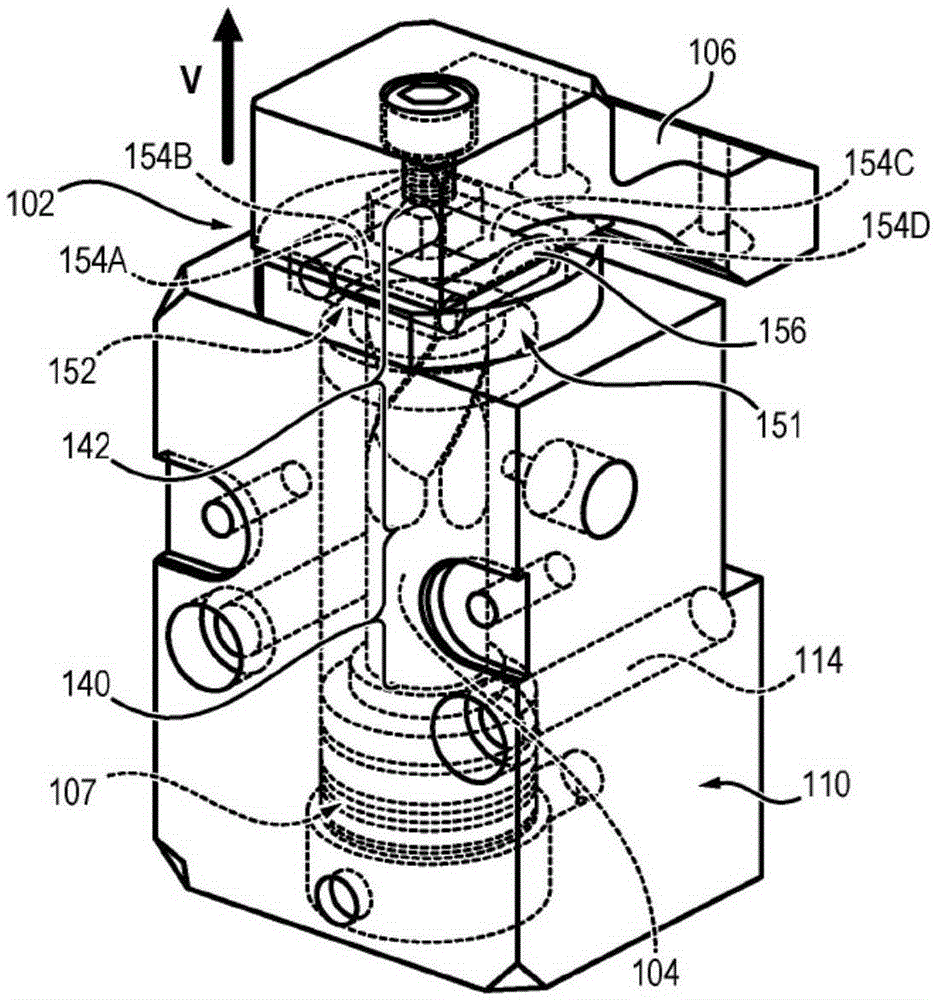

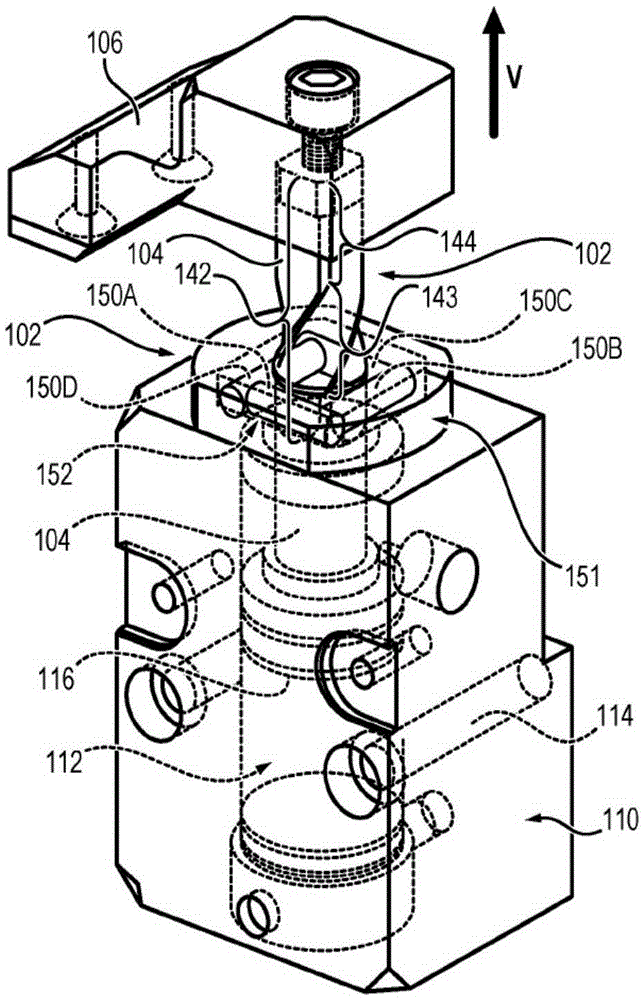

[0050] figure 1 A clamping cylinder 100 according to the invention is shown. As already explained, said clamping cylinders can be used in many applications and in different environments, even though an application of particular relevance to the Applicant is that in the field of energy storage, including in particular energy storage elements (in particular anodes, electrolytes and cathodes, The anode and cathode are equipped with stacks of different thin films of current collectors). The different films are actually stacked on the support and once stacked are moved to another station of the assembly chain, for example enclosing the stack in a mechanical cover. For this operation, at least one clamping cylinder according to the invention is used, which clamps the different stacked films during transport in order to hold the stack in such a way that each layer is not displaced relative to each other and does not Will be displaced relative to the support until after reaching the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com