A professional tobacco leaf grading table

A countertop and tobacco technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problem of difficult separation of tobacco leaves, sand, and broken leaves, and achieve the effect of saving collection and processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

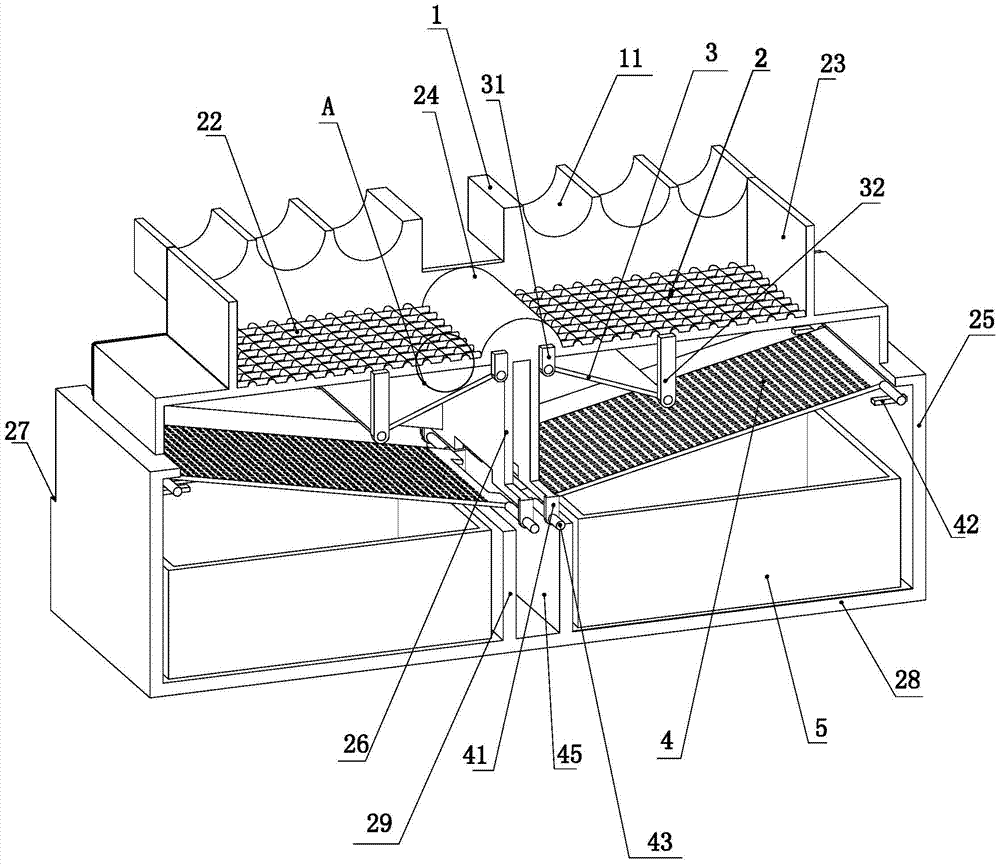

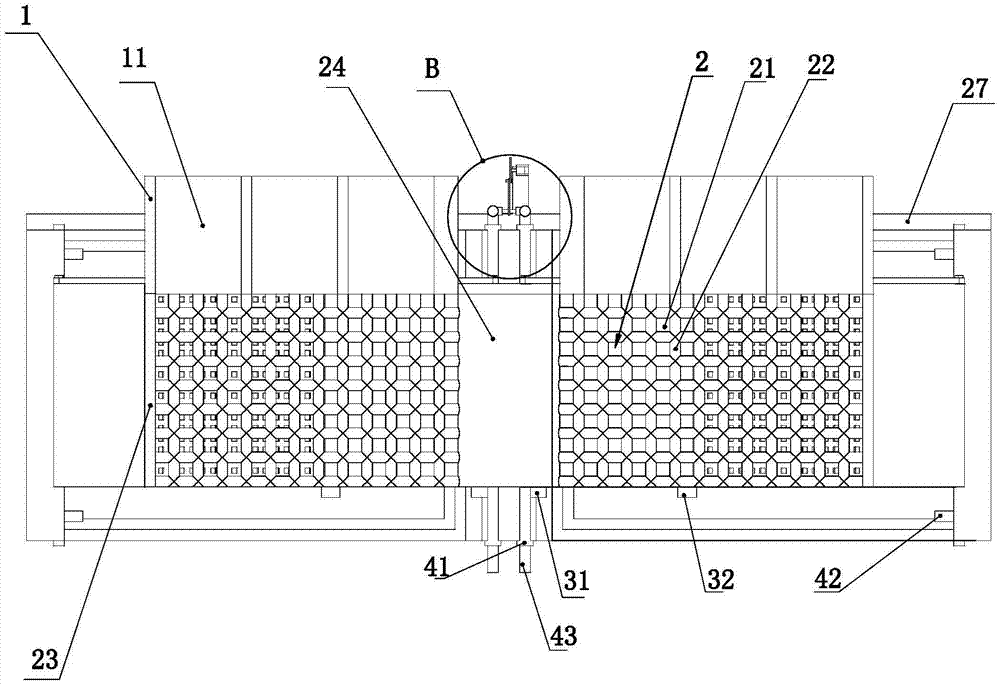

[0027] Such as Figure 1 to Figure 7 Shown, the present invention mainly comprises storage board 1, desktop 2, table hole 21, strip 22, inclined plate 3, sieve plate 4, sieve hole 46, soil box 5, motor 6, runner 7, connecting rod 8 and Connecting rod 9, in order to better illustrate the present invention, below in conjunction with accompanying drawing, the present invention will be described in detail.

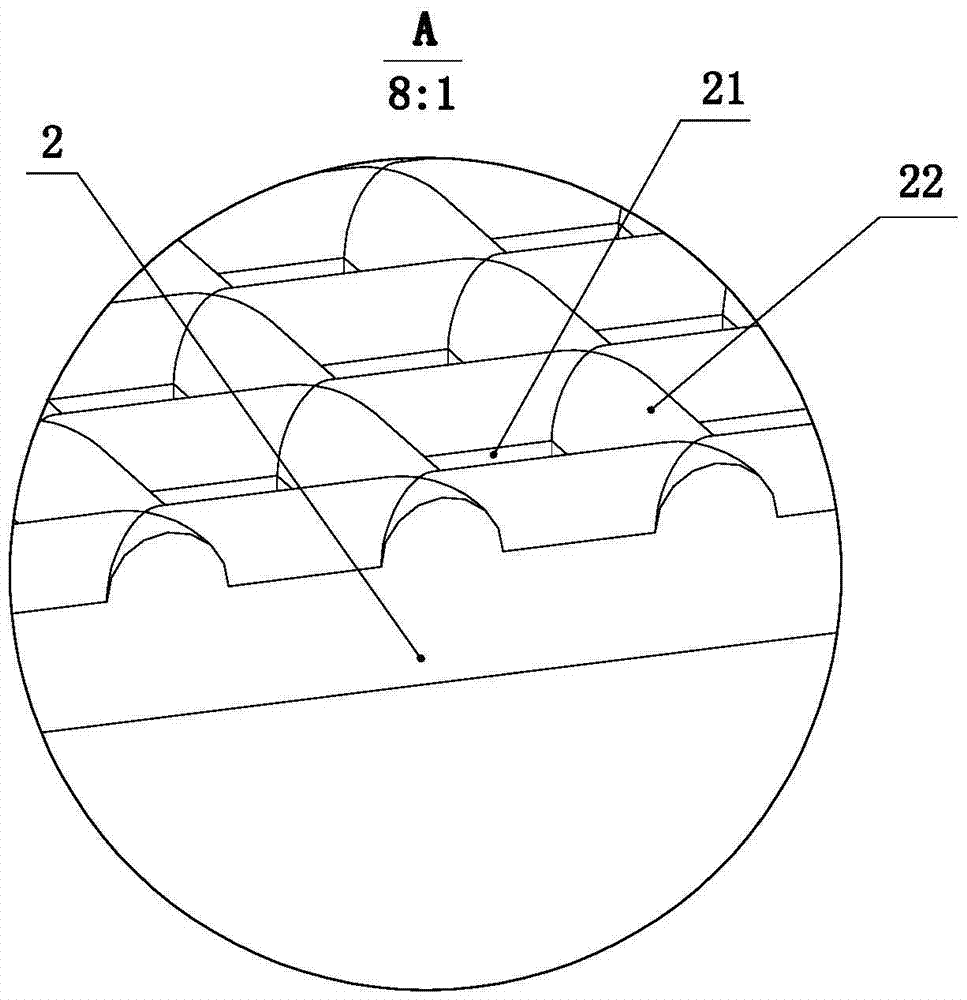

[0028] Such as figure 1 As shown, the section of the isolation block 24 is a semicircle, and the arc surface of the isolation block is arranged upwards. The left and right sides of the isolation block 24 are symmetrically fixedly installed with the desktop 2, and the rear side of the desktop is fixedly installed. Material storage plate 1 is provided with a "U" shaped material storage tank 11 for placing graded tobacco leaves on the material storage plate, and a vertical baffle plate 23 is fixedly installed on the side of the desktop away from the isolation block. The baffle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com