Preparation method of composite photocatalyst film for degrading phenol in water

A photocatalyst and composite light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult separation, achieve improved separation rate, cheap and easy-to-obtain raw materials, and improved absorption range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

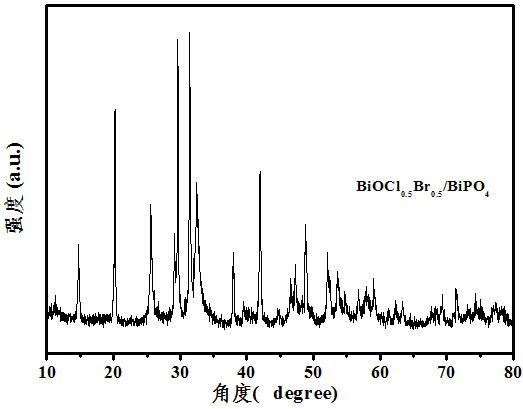

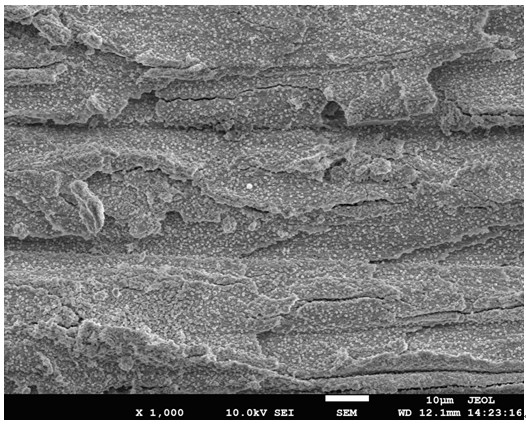

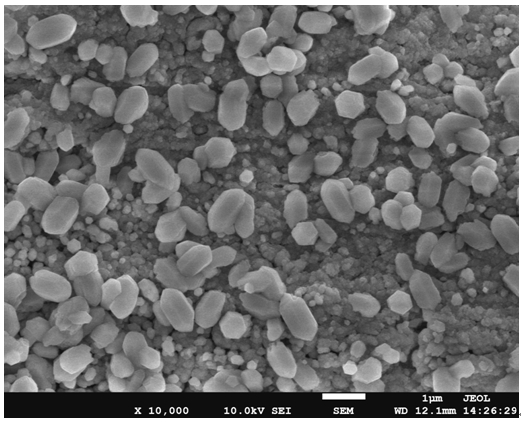

[0022] Weigh 0.01moL of potassium chloride, 0.01moL of potassium bromide and 0.01moL of potassium dihydrogen phosphate, and dissolve them in 100mL of distilled water to prepare an electrolyte solution. The metal bismuth plate and titanium plate were polished, washed with ethanol and deionized water, and dried; the bismuth plate was used as the anode, and the titanium plate was used as the cathode, which were placed in the electrolyte solution and electrolyzed for 4 hours under the condition of 4V voltage and magnetic stirring. After the reaction, the anode Bi plate was washed three times with absolute ethanol and deionized water, and then dried naturally at room temperature to obtain BiOCl 0.5 Br 0.5 / BiPO 4 Composite photocatalyst film.

[0023] The obtained photocatalyst film was used to degrade phenol solution. The reaction conditions are: under normal temperature and pressure, 50mL of 10mg / L phenol solution, using the prepared film as a photocatalyst, blowing air into t...

Embodiment approach 2

[0025]Weigh 0.01moL of potassium chloride, 0.01moL of potassium bromide and 0.01moL of potassium dihydrogen phosphate, and dissolve them in 100mL of distilled water to prepare an electrolyte solution. After the metal bismuth plate and titanium plate are polished, they are cleaned and dried with ethanol and deionized water successively; the bismuth plate is used as the anode and the titanium plate is used as the cathode, which are placed in the electrolyte solution and electrolyzed for 3.5 hours under the condition of 8V voltage and magnetic stirring . After the reaction, the anode Bi plate was washed three times with absolute ethanol and deionized water, and then dried naturally at room temperature to obtain BiOCl 0.5 Br 0.5 / BiPO 4 Composite photocatalyst film.

[0026] The obtained photocatalyst film was used to degrade phenol solution. The reaction conditions are: under normal temperature and pressure, 50mL of 10mg / L phenol solution, using the prepared film as a photoca...

Embodiment approach 3

[0028] Weigh 0.01moL of potassium chloride, 0.01moL of potassium bromide and 0.01moL of potassium dihydrogen phosphate, and dissolve them in 100mL of distilled water to prepare an electrolyte solution. After grinding the metal bismuth plate and titanium plate, they were cleaned and dried with ethanol and deionized water successively; the bismuth plate was used as the anode and the titanium plate was used as the cathode, which were placed in the electrolyte solution and electrolyzed for 3 hours under 12V voltage and magnetic stirring conditions. After the reaction, the anode Bi plate was washed three times with absolute ethanol and deionized water, and then dried naturally at room temperature to obtain BiOCl 0.5 Br 0.5 / BiPO 4 Composite photocatalyst film.

[0029] The obtained photocatalyst film was used to degrade phenol solution. The reaction conditions are: under normal temperature and pressure, 50mL of 10mg / L phenol solution, using the prepared film as a photocatalyst, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com