Porous negative pressure cooling structure for dental handpieces

A technology of dental handpiece and cooling structure, which is applied in the fields of dental drilling, dentistry, medical science, etc. It can solve the problems of inadequate cooling, structural limitations, and actual operation of water outlet blockage, so as to ensure the cooling effect, prevent water and air leakage, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

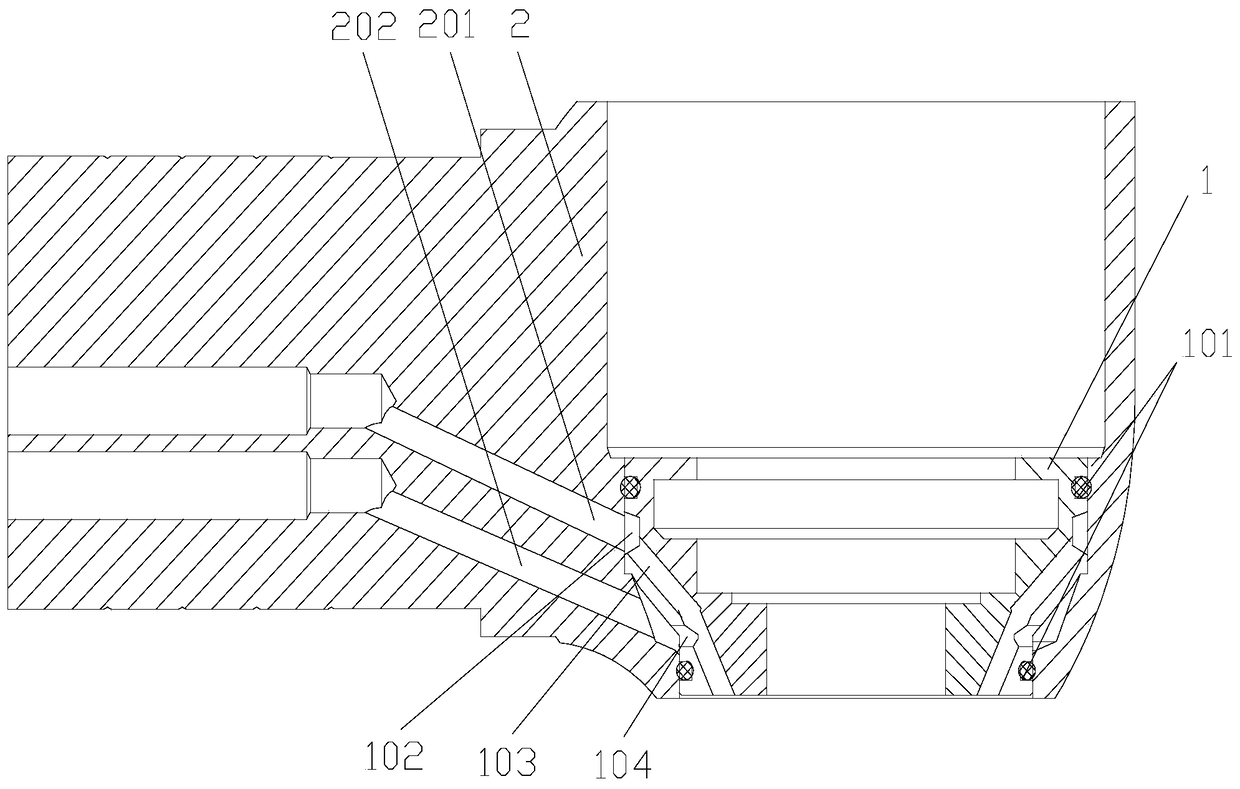

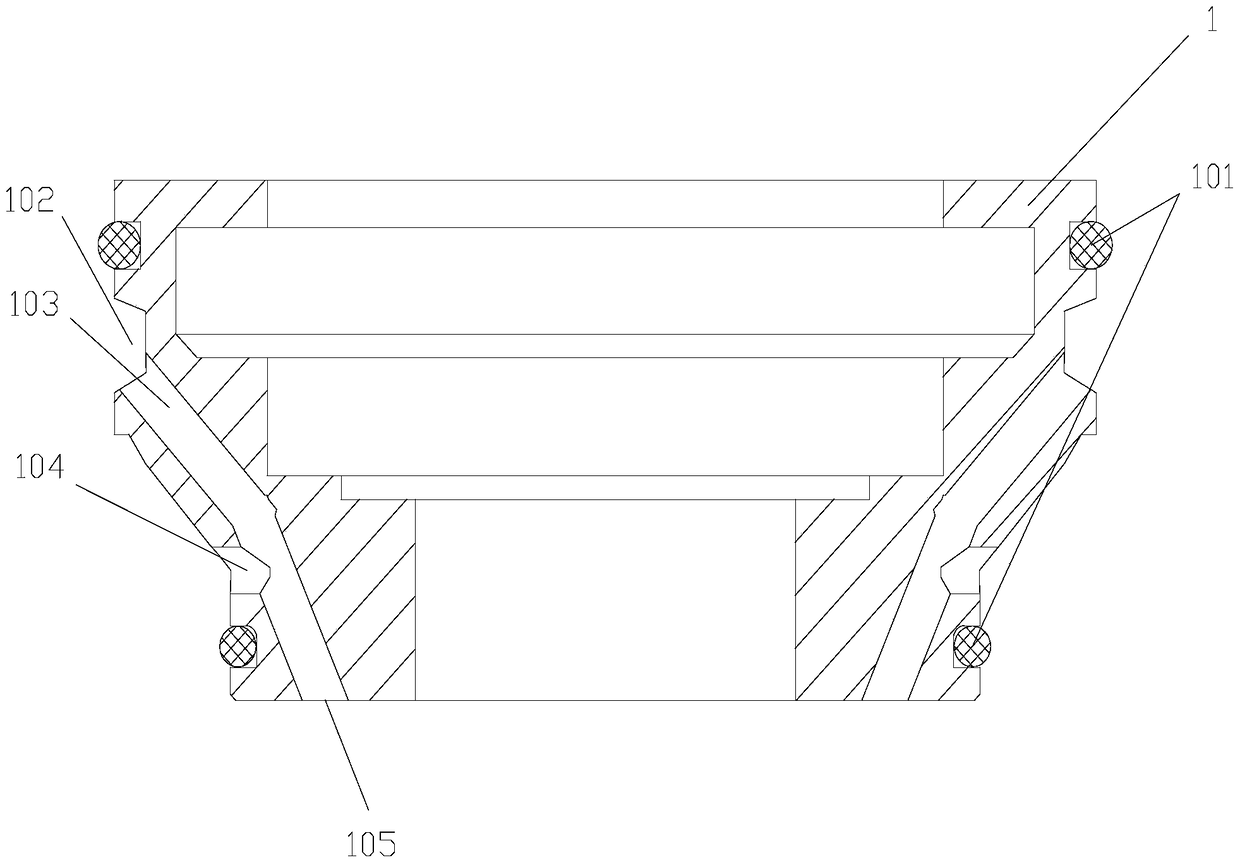

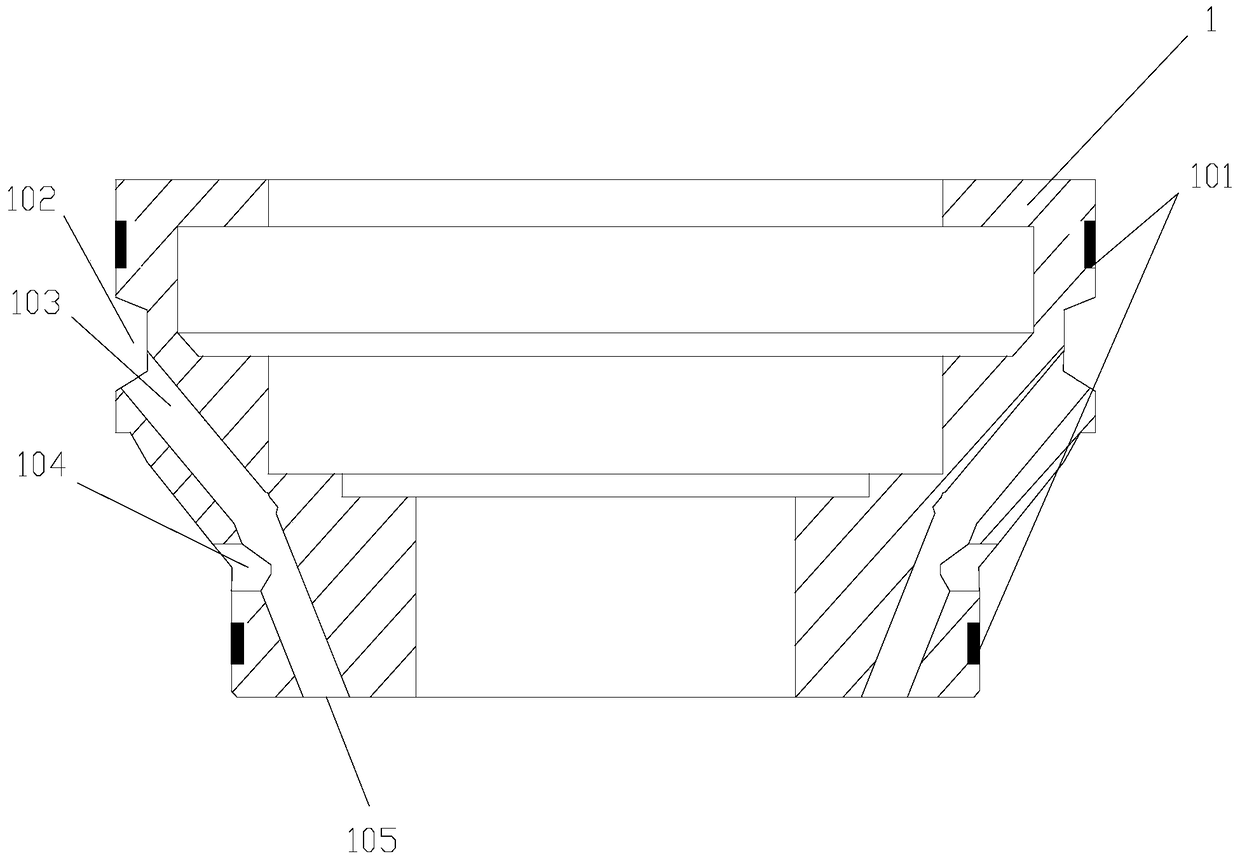

[0018] Attached below Figure 1-4 An embodiment of the present invention is described.

[0019] The porous negative pressure cooling structure for the dental handpiece has a spray seat 1 which is a hollow cylindrical member, and the spray seat 1 is adapted to the head shell 2 and fixed in the head shell 2 at the end of the handle of the dental handpiece. Specifically, the small end of the spray seat 1 is placed inside the nose shell 2 and pressed tightly, so that the lower end surface of the spray seat 1 is aligned with the lower end surface of the nose shell, and the gap between the head shell 2 and the end surface of the spray seat 1 is sealed with glue. .

[0020] Both the upper end and the outer wall of the lower end of the spray seat 1 are formed with annular grooves 101 for water and air sealing, in order to achieve a better sealing effect and prevent water and air leakage. Specifically (such as figure 2 As shown), the O-shaped rubber ring is nested in the annular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com