A filter dust removal device

A technology of dust removal device and filter screen, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of frequent operation, poor dust removal effect, and waste of resources, so as to reduce the number of replacements, avoid waste, Guaranteed close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

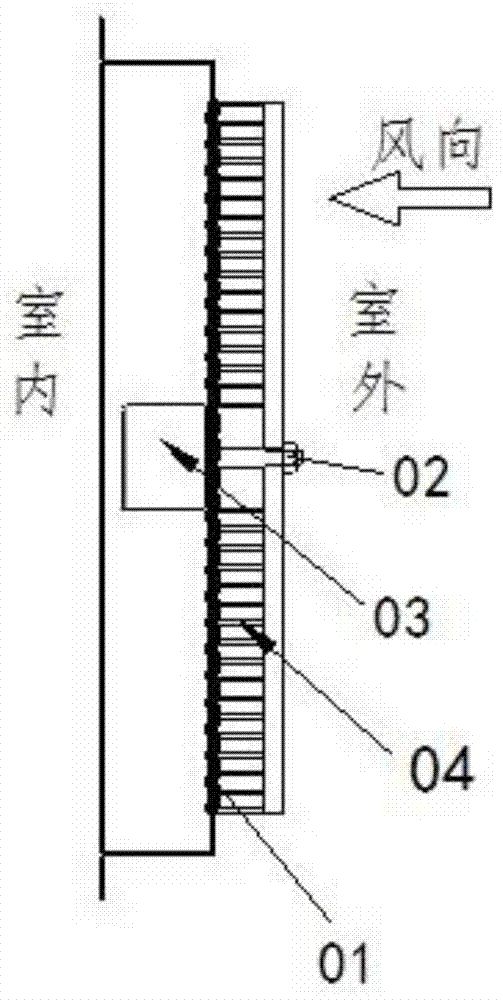

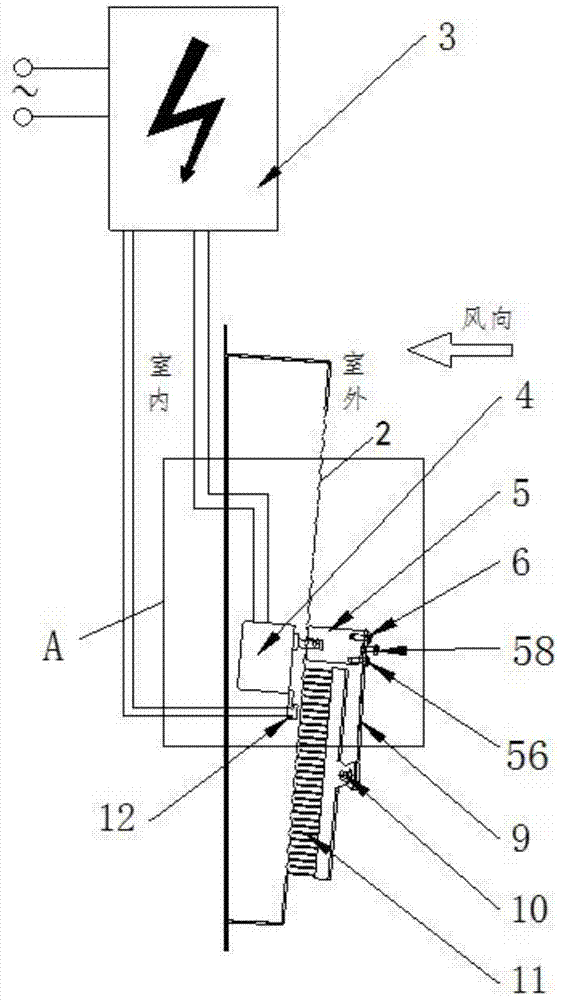

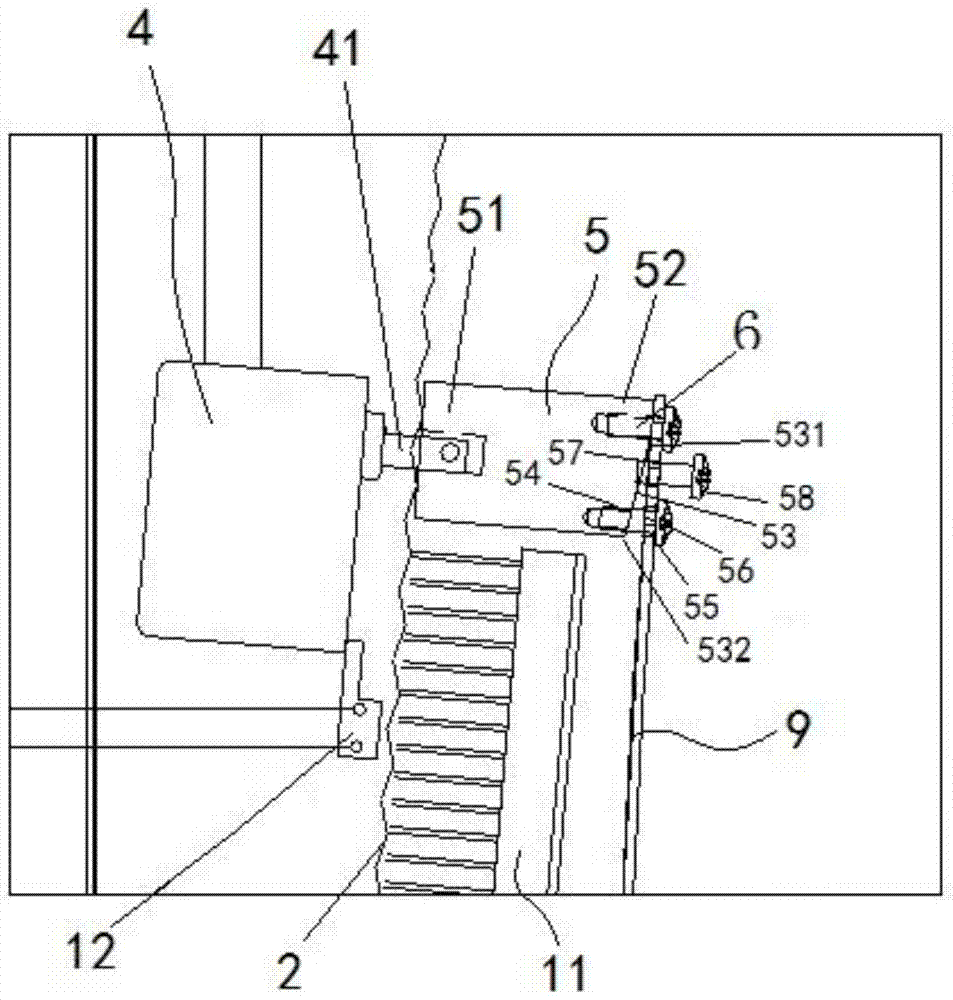

[0045] This embodiment provides a filter screen dust removal device, such as Figure 2 to Figure 4As shown, it includes a motor 4, an adapter 5 and an elastic pressing member 9; wherein, the motor 4 is installed on the filter screen 2, the filter screen 2 is installed on the frame 1, and the motor 1 has a The output shaft 41; the adapter 5 has a connection end 51 fixedly connected to the output shaft 41, and an installation end 52 opposite to the connection end 51; one end of the elastic pressing member 9 is connected to the installation end 52 through the installation structure Fixedly connected, the other end is equipped with a brush 11, which is used to elastically press the brush 11 toward the filter screen 2, so that the bristles of the brush 11 are always in close contact with the filter screen 2.

[0046] In the filter dust removal device of this embodiment, when the motor 4 starts to work, the elastic pressing member 9 rotates with the output shaft 41, and then drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com