Lattice type or overflow ball mill unit

A ball mill and overflow type technology, which is applied in the equipment of mine beneficiation test and school field, can solve the problems of large floor area, uncompact connection between processes, unsuitable for continuous open and closed circuit grinding experiments, etc., to save space , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

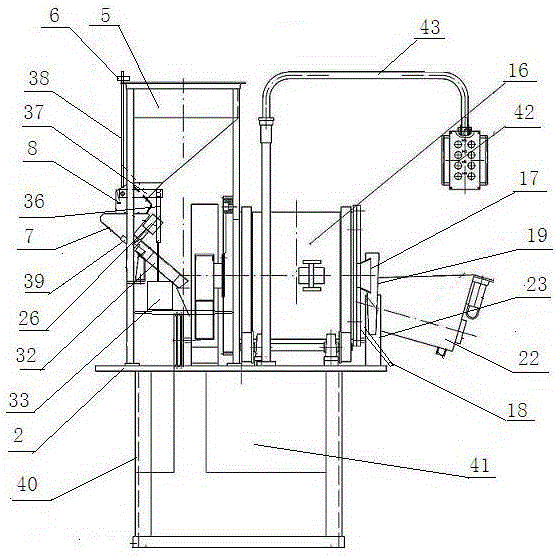

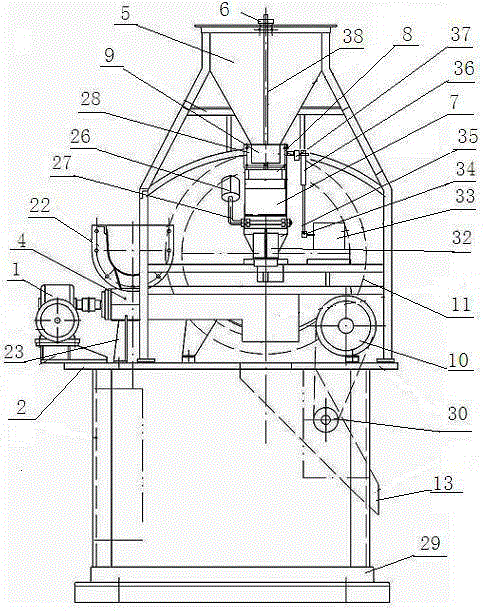

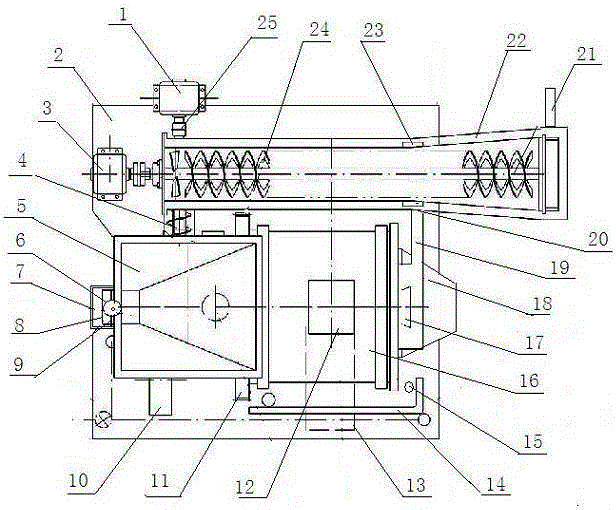

[0014] The grid-type and overflow-type ball mill units in the figure include frame 2, hopper 5, feeding structure, overflow ball mill 16, screw feeder 4, screw classifier 22, controller, and the feeding structure, grid-type or overflow Flow ball mill 16, screw feeder 4, and spiral classifier 22 are driven by separate motors; grid type or overflow ball mill 16, screw feeder 4, and screw classifier 22 are installed on the frame 2 platform; grid type or overflow ball mill 16. The screw classifier 4 is installed in parallel. The installation position of the screw feeder 4 is perpendicular to the overflow ball mill 16 and the screw classifier 4. The feed port of the screw feeder 4 is located below the discharge port of the screw classifier 22. The port is connected with the overflow ball mill 16 feed port; the material outlet 17 of the lattice type or overflow ball mill 16 is provided with a material guide mechanism to connect the spiral classifier 22 or a direct discharge trough 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com