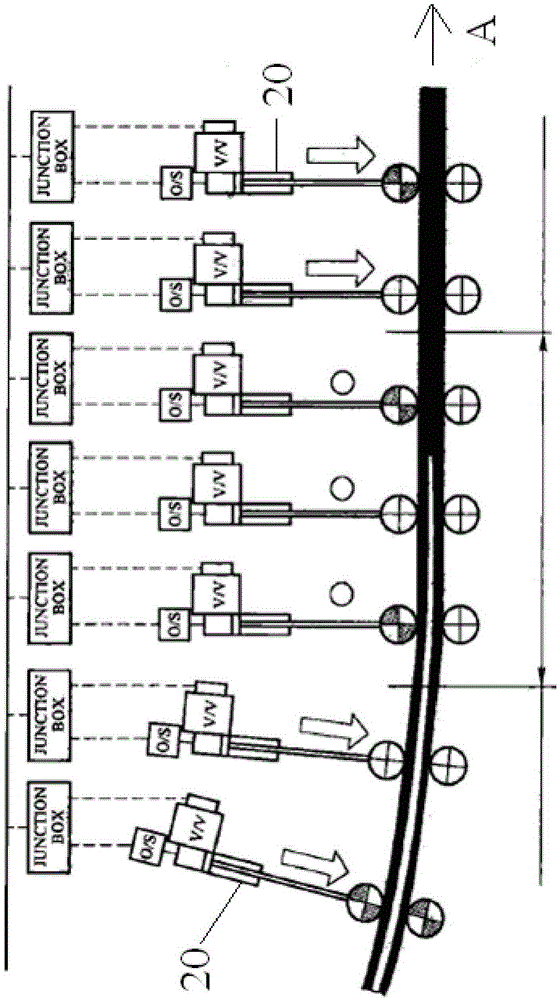

Fan-shaped section type withdrawal and straightening device and withdrawal and straightening equipment

A segment and equipment technology, which is applied in the field of continuous casting equipment, can solve the problems of large distance between the front and rear rolls, etc., and achieve the effect of reducing light reduction, improving efficiency and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

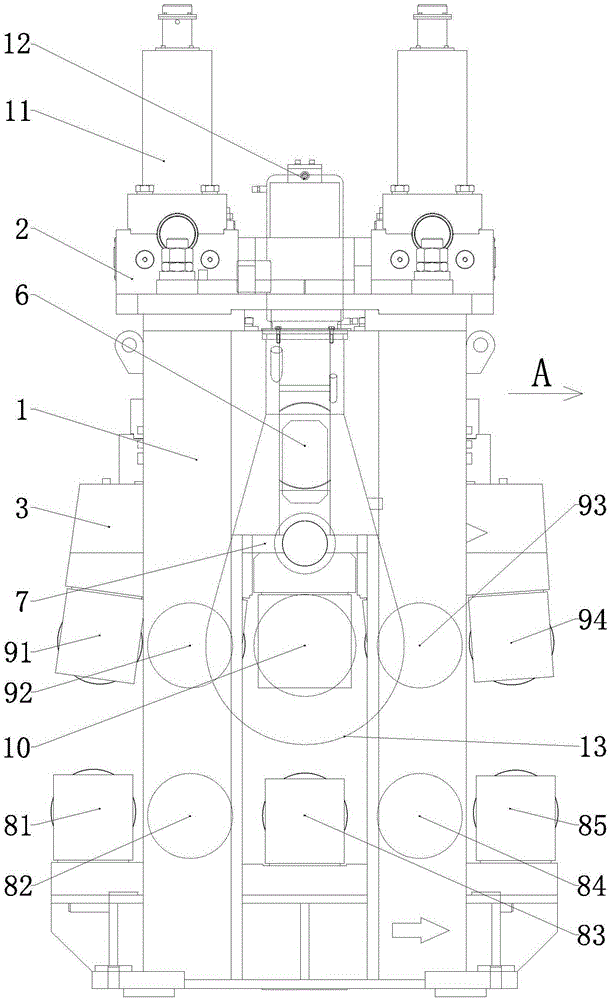

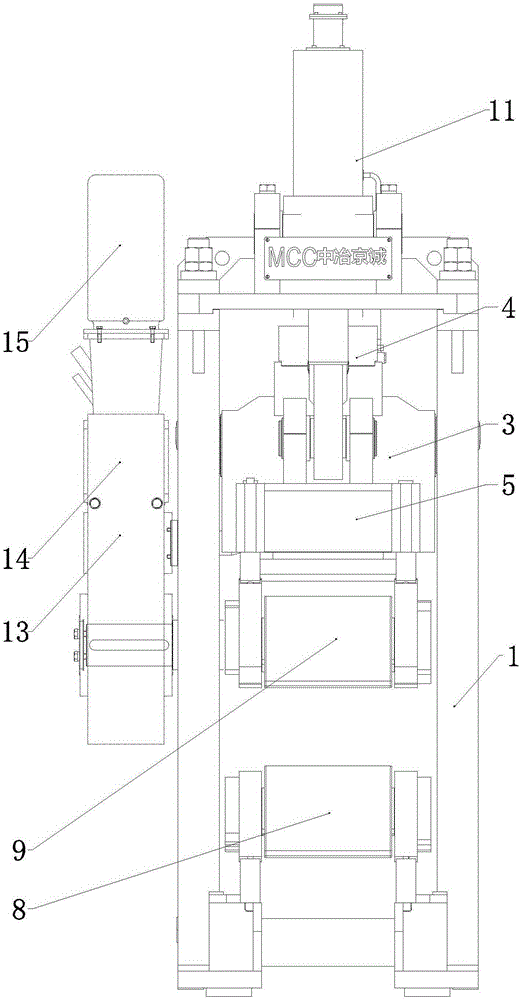

[0032] A sector-type tension leveling device 30 is composed of a frame 1 and five pairs of work rolls arranged sequentially along the rolling side A (respectively figure 2 The first pair of work rolls, the second pair of work rolls, the third pair of work rolls, the fourth pair of work rolls and the fifth pair of work rolls are arranged in sequence from left to right), and the five pairs of work rolls are arranged on the frame 1 inside, such as figure 2 with image 3 shown.

[0033] A frame 1 of the sector-type tension leveling device 30 contains five pairs of work rolls, that is, the tension leveler composed of five pairs of work rolls and a single frame replaces the existing single frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com