Machining workbench facilitating magnetic metal scrap recovery

A waste recycling and magnetic metal technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of scattered waste and easy scattering of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

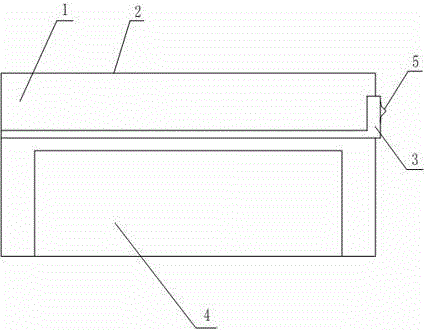

[0018] Such as figure 1 The shown processing workbench for recycling magnetic metal scraps includes a platform 1 for placing fixtures and power heads, the upper surface of the platform 1 is a mesh support plate 2 communicating with the interior of the platform 1, The inside of the table body 1 is provided with a drawer 3 that is pulled away from the side of the table body 1, and an electromagnet 4 fixed to the inside of the table body 1 is arranged below the drawer 3, and a handle 5 is provided on the drawer 3, so that Both the platform body 1 and the mesh support plate 2 are made of non-magnetic materials. During the use of this embodiment, first push the drawer 3 to the inside of the table body 1, place the fixture and the magnetic element to be processed on the table body 1, and perform normal processing work. Part of the waste is scattered on the surface of the table body 1 , and part of it falls into the drawer 3 through the mesh support plate 2 . After the processing i...

Embodiment 2

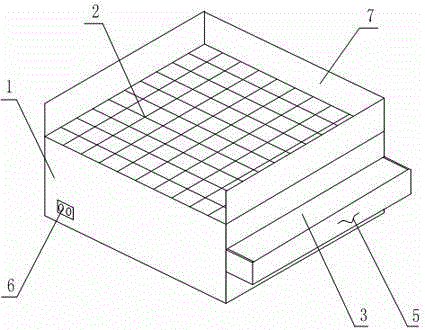

[0020] Such as figure 2 In the shown processing workbench for recycling magnetic metal scraps, on the basis of Embodiment 1, the drawer 3 is made of magnetic materials. Magnetic materials include iron, cobalt, nickel and their alloys and other magnetic substances. These materials have strong magnetization ability under the action of electromagnetic field, and can form new magnetic lines of induction, thereby enhancing the attraction to magnetic waste. And it can be demagnetized immediately after stopping the energization of the electromagnet, which does not affect the treatment of waste.

Embodiment 3

[0022] Such as figure 2 In the shown processing workbench for recycling magnetic metal scrap, on the basis of any of the above-mentioned embodiments, the power switch 6 of the electromagnet 4 is arranged on the side of the housing 1, and the edge of the upper surface of the table body 1 There is also a baffle 7 surrounded by three sides. The baffle plate 7 can avoid the problem that the waste chips in the processing process fall out of the table body and cause difficulty in cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com