Forming method of cavity type composite material part with lateral edge and convergence hole

A composite material and molding method technology, which is applied in the molding field of composite material parts with side edges and converging mouth cavity, can solve the problems of inability to demould, difficulty in manual layup, etc., and achieve the effect of improving the quality of inner and outer surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

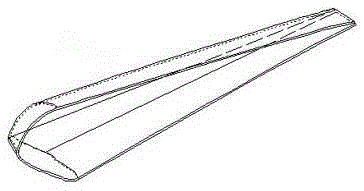

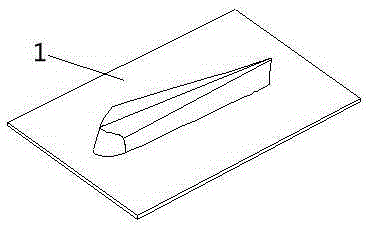

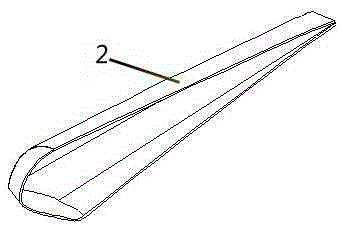

[0023] figure 1 It is a schematic diagram of a composite material part with a side edge and a convergent cavity in a specific embodiment. This part is a kind of one end opening convergent, that is, the cross section inside the cavity is larger than the cross section of the opening, the cavity cross section is streamlined, and the side edge at one end is sharp. The corners are acute-angled composite cover-shaped parts.

[0024] A molding method of a composite material part having a side edge and a converging cavity of the present invention is characterized in that it comprises the following steps:

[0025] Step 1, laying the prepreg sheet on the outer surface of the male mold 1 to form a material layer;

[0026] Step 2, the pre-compacted material layer is removed from the male mold 1, the opening of the material layer is placed upwards in the combined female mold 4, and sequentially placed in the cavity of the material layer Soft mold 2 and core mold 3;

[0027] Step 3, pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com