Vertical take-off and landing unmanned aerial vehicle

A technology for vertical take-off and landing of drones, applied in the field of drones, which can solve problems such as slow horizontal flight speed, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the prior art, unmanned aerial vehicles either need to rely on long runways, and need to maintain sufficient horizontal flight speed after take-off; or the horizontal flight speed is relatively slow.

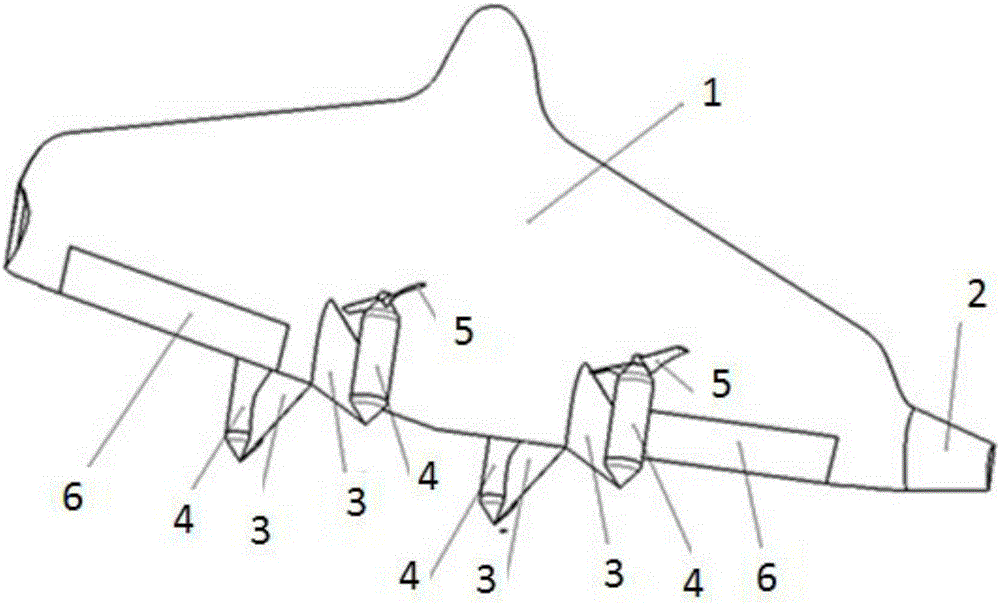

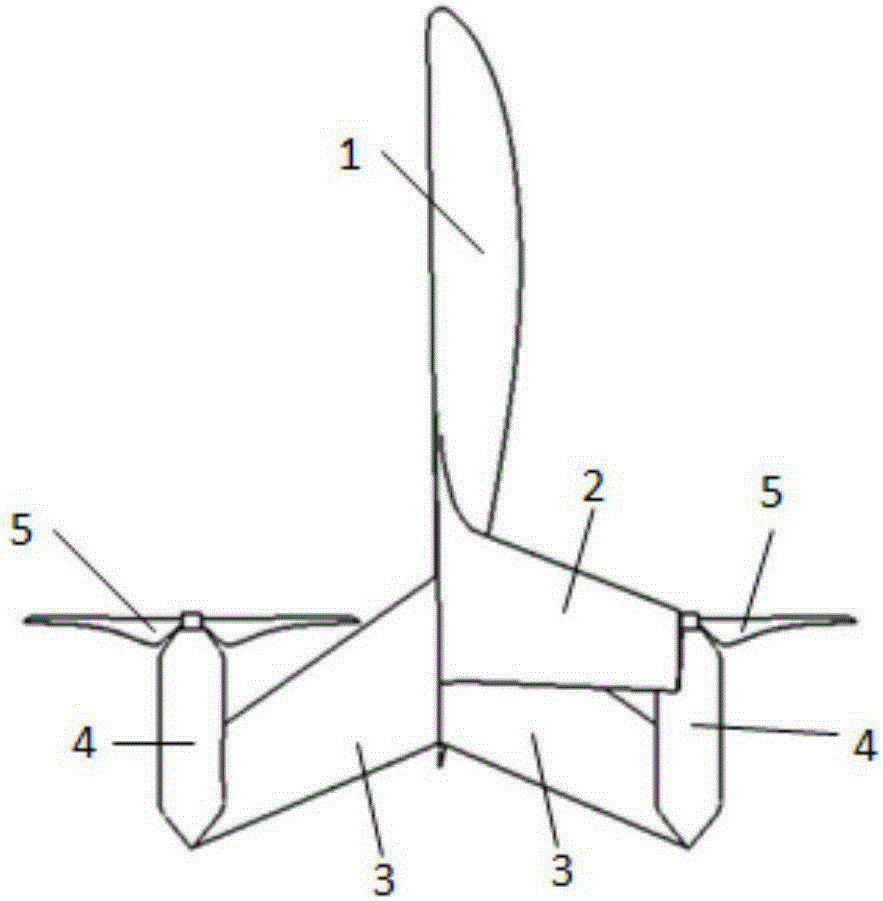

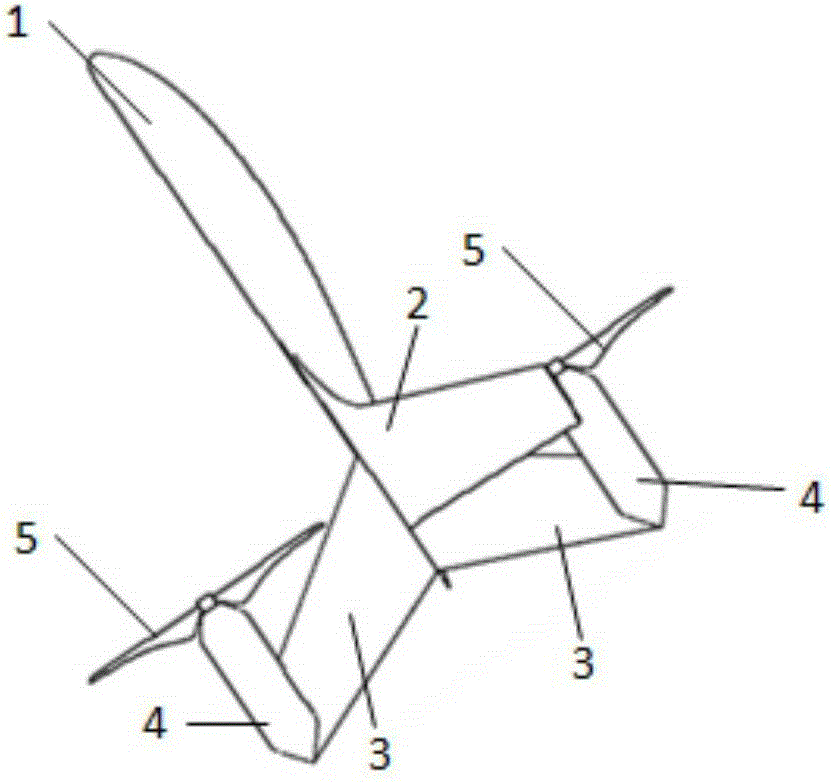

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Compared with fixed-wing drones, vertical take-off and landing drones can take off and land at zero speed, have the ability to hover, and can fly horizontally in the way of fixed-wing flight. Vertical take-off and landing drones are independent of runways and have the advantage of being able to hover.

[0033] VTOL UAVs have much higher forward flight speeds and greater range than rotary-wing UAVs.

[0034] Based on these advantages, vertical take-off and landing drones are especially suitable for occasions that require hov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com