Automatic pump pressure type toothpaste package bottle

一种自动泵、包装瓶的技术,应用在牙膏包装瓶领域,能够解决活塞不能及时上移、弹性体固定不好、易发生脱落等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

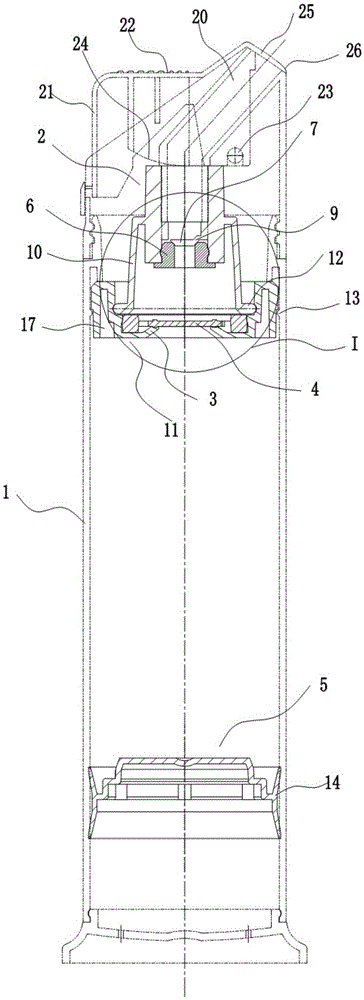

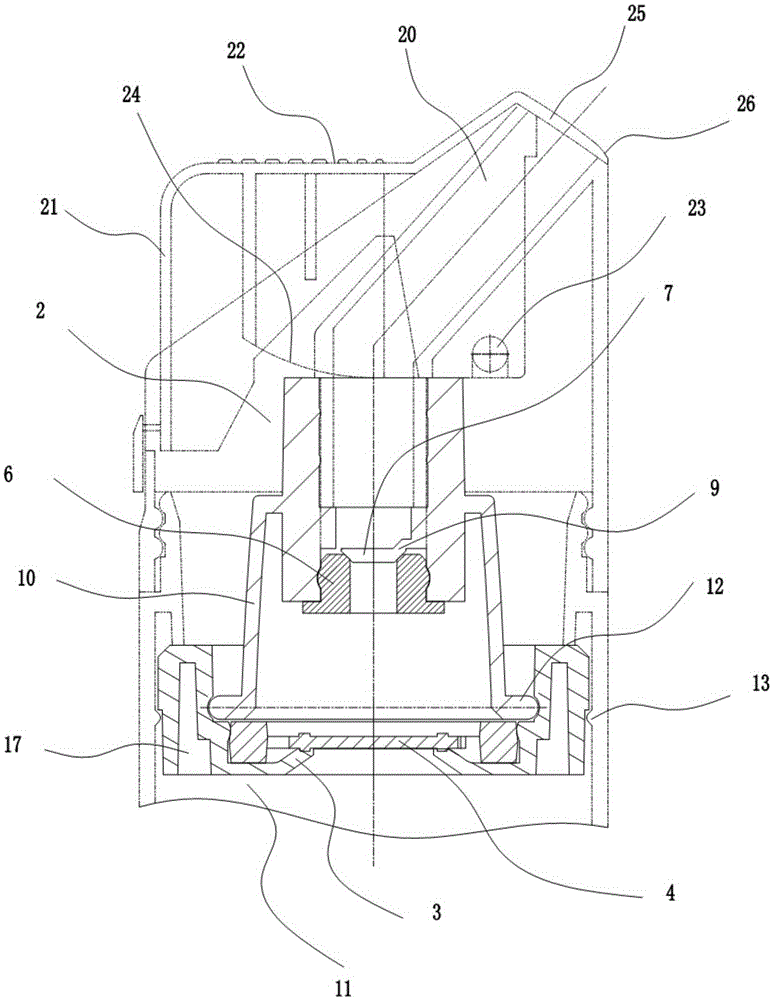

[0019] The present invention will be further described below in conjunction with accompanying drawing:

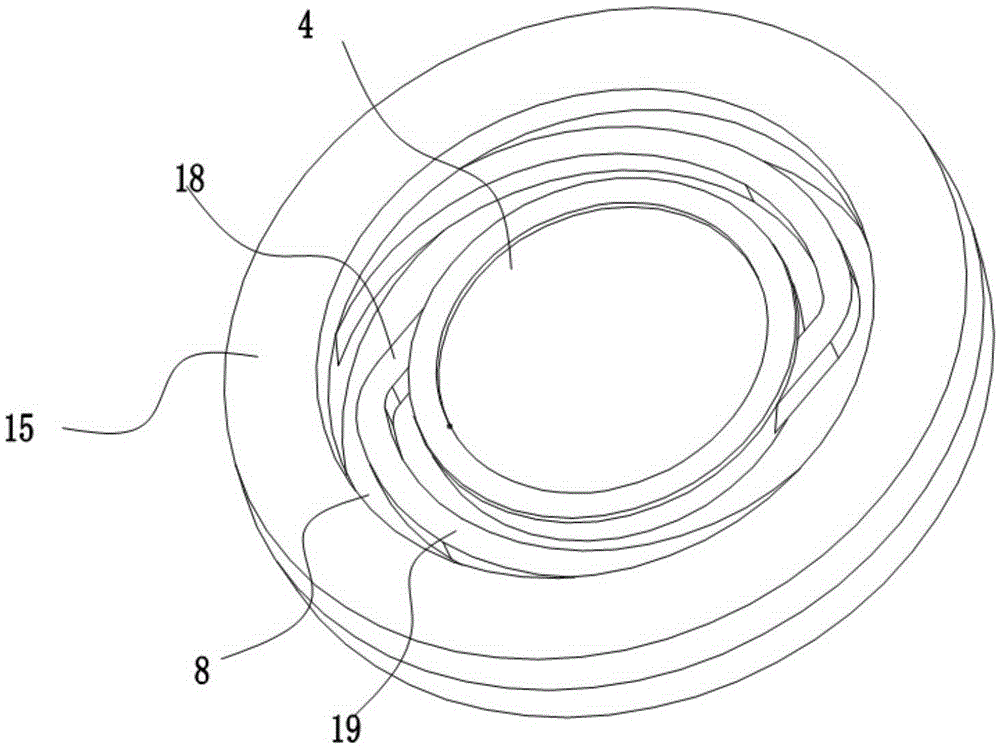

[0020] as attached figure 1 , figure 2 and image 3 As shown, the automatic pumping toothpaste packaging bottle includes a bottle body 1 with an open upper end, and a valve housing 2 whose inner cavity volume can be changed is installed in the bottle body 1, and the upper end and the lower end of the valve housing 2 are respectively provided with There is an opening, and a lower valve seat 3 is provided at the opening of the lower end of the valve housing, and a lower sealing sheet 4 located above the lower valve seat 3 is arranged inside the valve housing 2, and the lower sealing sheet 4 and the lower sealing sheet 4 A sealing pair is provided between the valve seats 3, a connection device is provided between the lower sealing sheet 4 and the valve housing 2, and a cavity for the lower sealing sheet to open upward is provided in the valve housing 2 , the upper opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com