Bonded insert mounting tensioner

A tensioning device and insert technology, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problem that the insert nut and the fastening hole are not completely adhered and adhered, the connection strength is reduced, and the connection strength of the insert is affected, etc. problems, to achieve the effect of eliminating the influence of human factors, effective connection and fixation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below by embodiment the present invention will be further described:

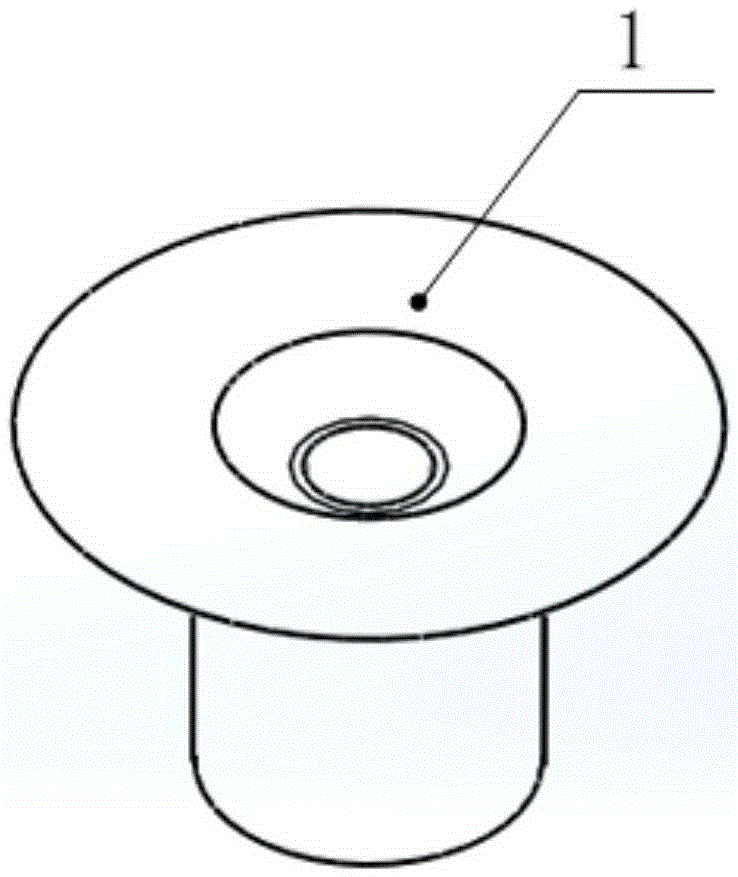

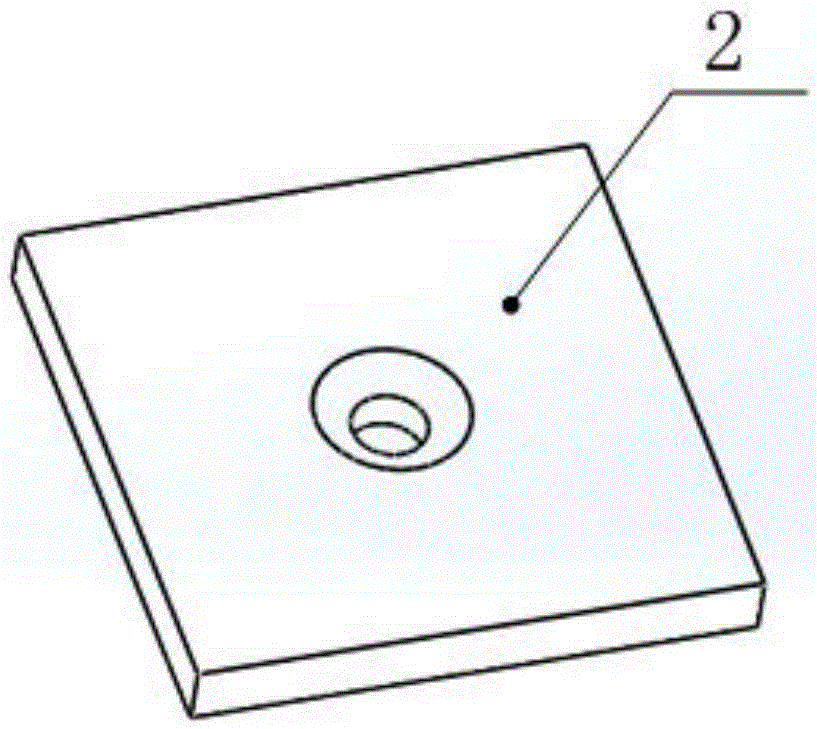

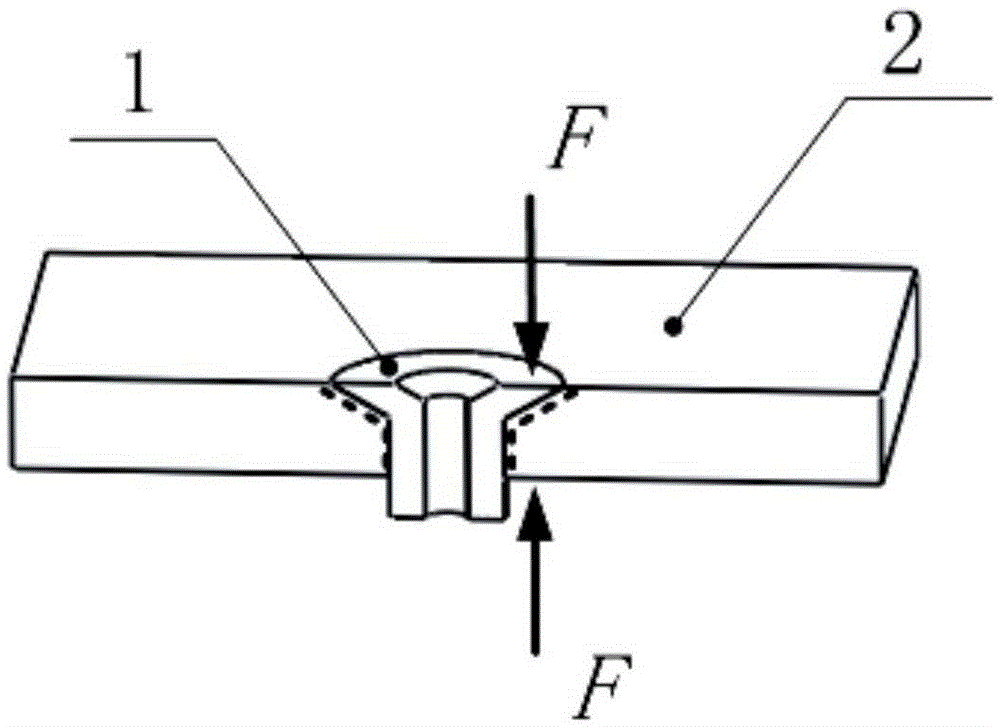

[0020] Please also see Figure 4 with Figure 5 ,in, Figure 4 It is a schematic diagram of the structure of the tensioning device for installing the bonding inlay of the present invention; Figure 5 yes Figure 4 The A-A cutaway diagram. The tensioning device for installing the adhesive insert includes an insert, a mounting plate, a tension rod, and a spring sheet. Among them, the inlay has a threaded hole in the middle, which is glued into the fastening hole of the mounting plate, the spring piece is folded into a groove structure, the two bottom surfaces are in contact with the bottom surface of the mounting plate, and a card with two symmetrical cards is set in the middle of the groove structure. One end of the tension rod is screwed to the inlay, and the other end passes through the slot of the spring sheet and is fixed by the card.

[0021] Such as Image 6 As shown, a support platform i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com