Noise control methods for waste heat boilers in target power plants under construction or pre-construction

A power plant waste heat and noise control technology, applied in the field of power plants, can solve the problems of unsatisfactory requirements, unsatisfactory noise reduction effect, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

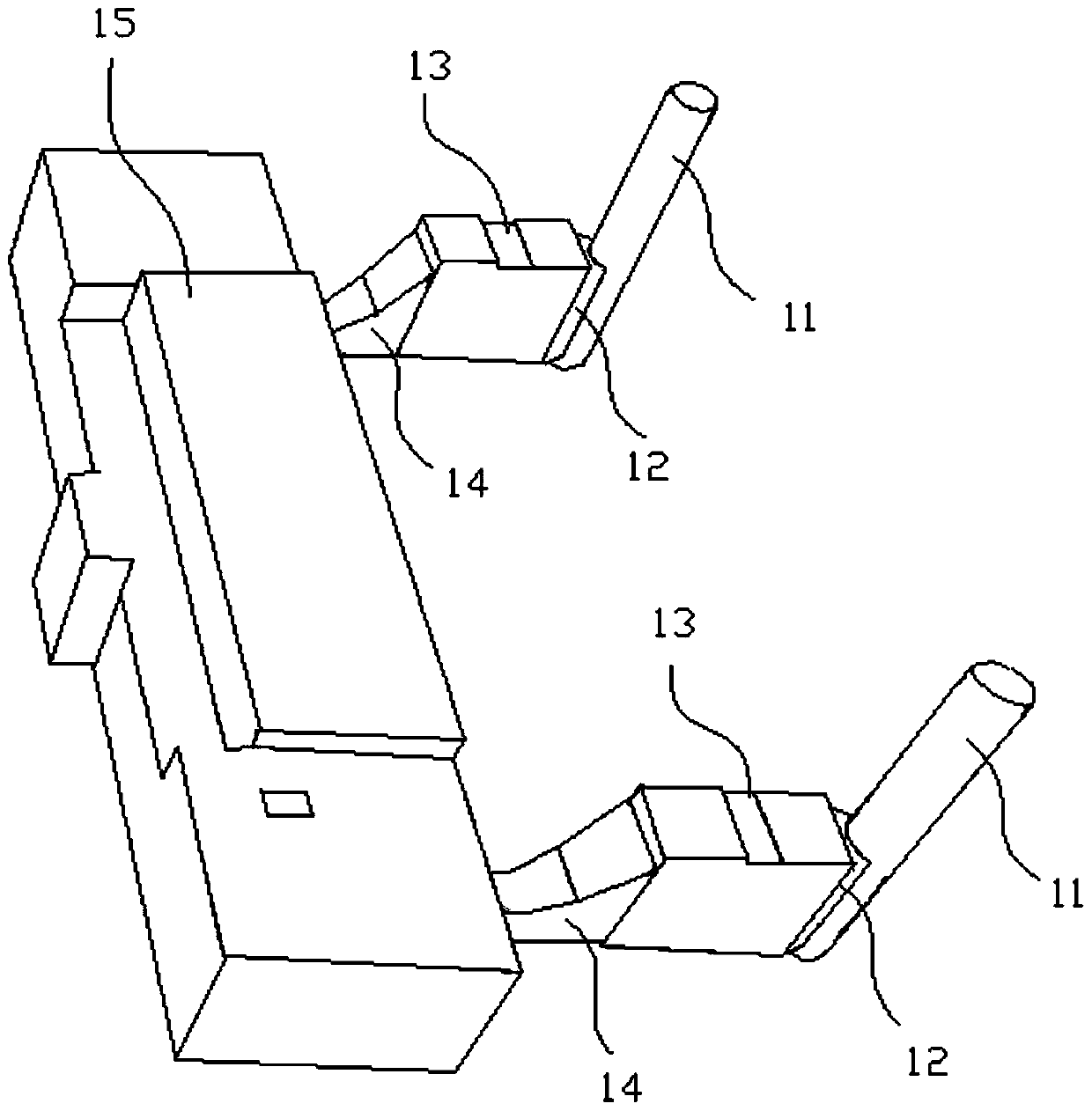

[0052] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

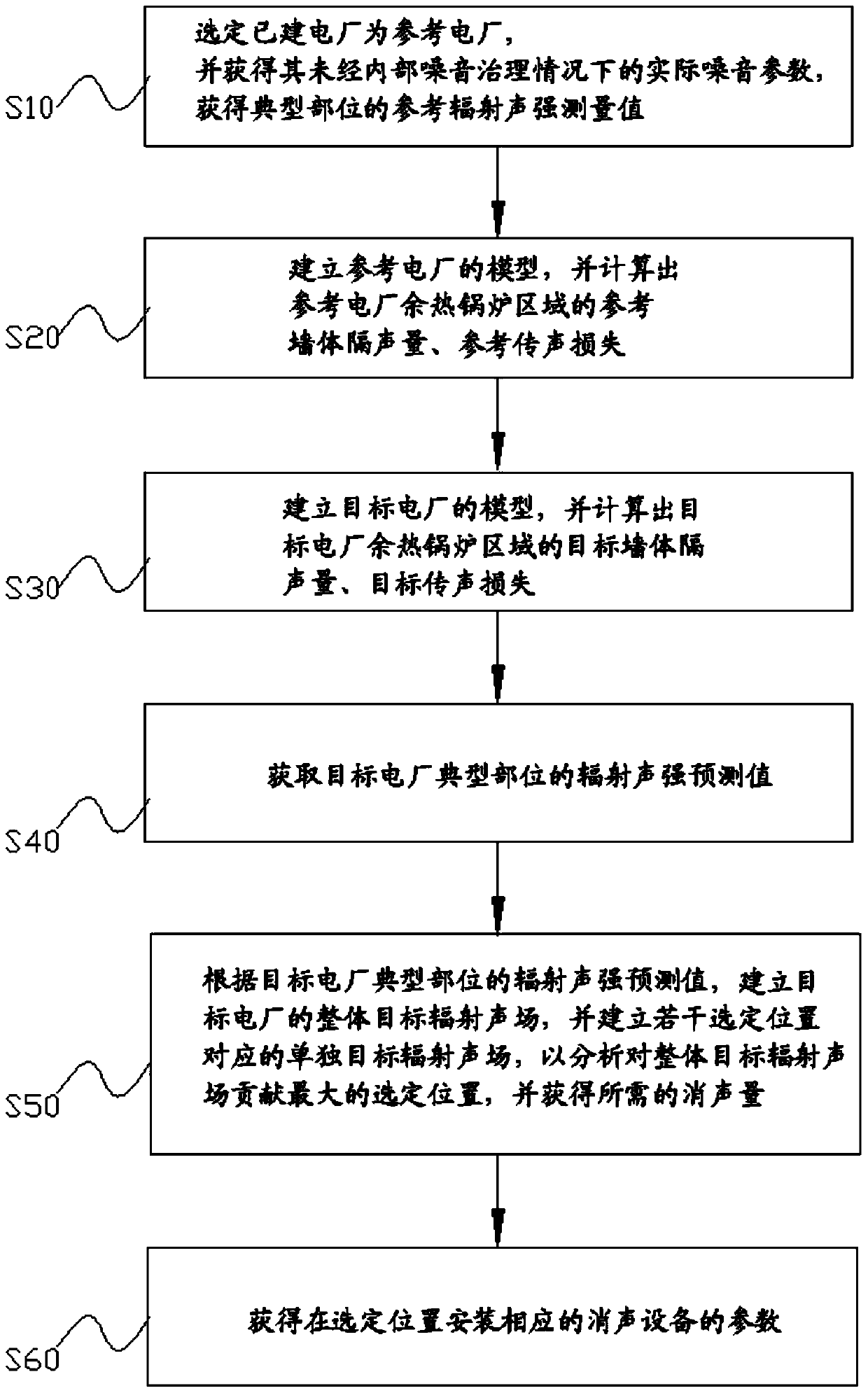

[0053] Please refer to figure 1 , figure 1 It is a flow chart of a specific embodiment of the noise control method for the waste heat boiler of the target power plant provided by the present invention.

[0054] The target power plant of the present invention is a power plant under construction or pre-construction, that is, the power plant has not yet been constructed, or the infrastructure is being constructed, but the waste heat boiler, chimney, etc. have not yet been established, or have not yet been established, which does not hinder the installation of noise reduction equipment; A power plant that has been built refers to a physical power plant that has been built.

[0055] The noise control method comprises the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com