Pigment mixing device for oil painting drawing

A mixing device and paint technology, applied in decorative art, painting tools, etc., can solve the problems of increasing the workload of painters, adverse environmental effects, painting pollution, etc., to avoid redeploying paint, simple and fast replacement operation, and prevent sticking Attached to the wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

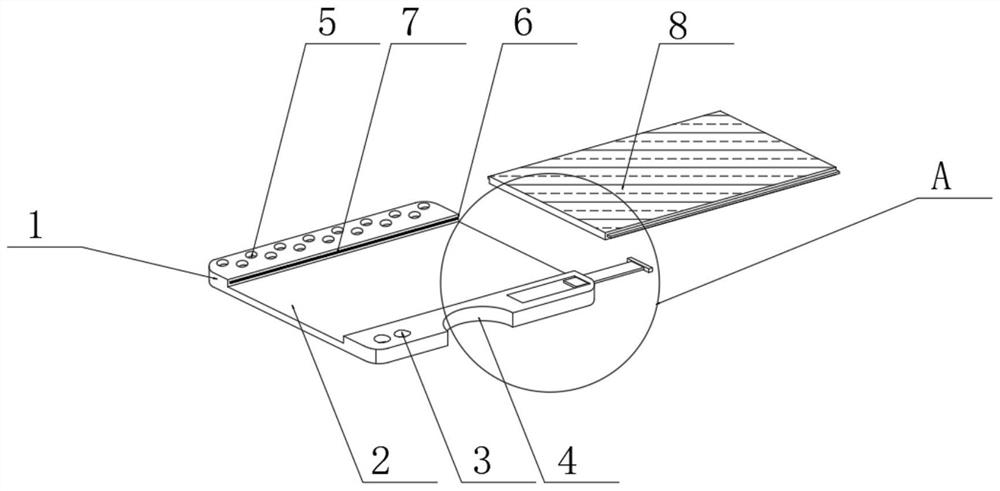

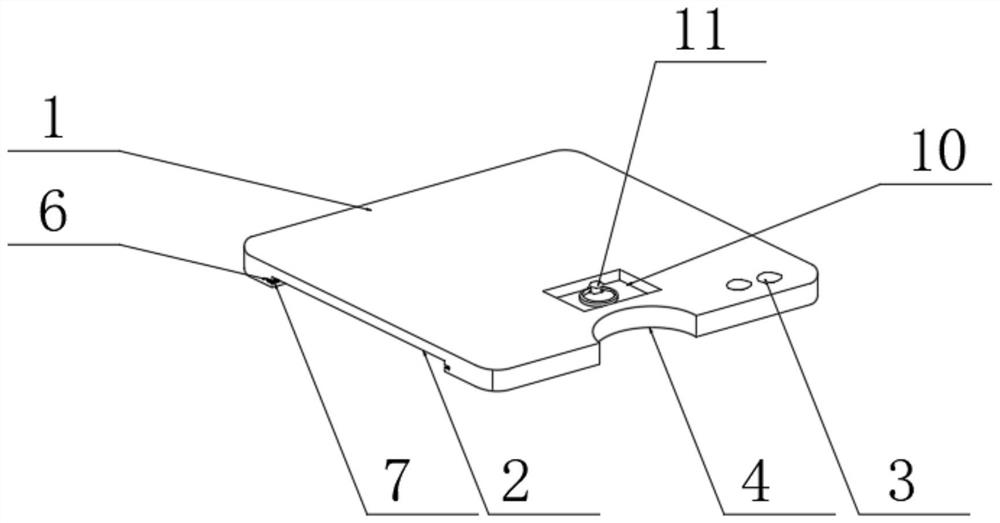

[0036] see Figure 1-8 , in an embodiment of the present invention, a pigment mixing device for oil painting, comprising a palette 1, a palette 8, a rotating mixing assembly, the palette 1, the upper surface of the palette 1 is provided with The first installation groove 2, and the upper surface of the palette 1 is provided with an oil groove 3 at a position close to the first installation groove 2, which is characterized in that,

[0037] The palette 8 is installed in the first installation groove 2 on the palette 1 so that it can slide in / out;

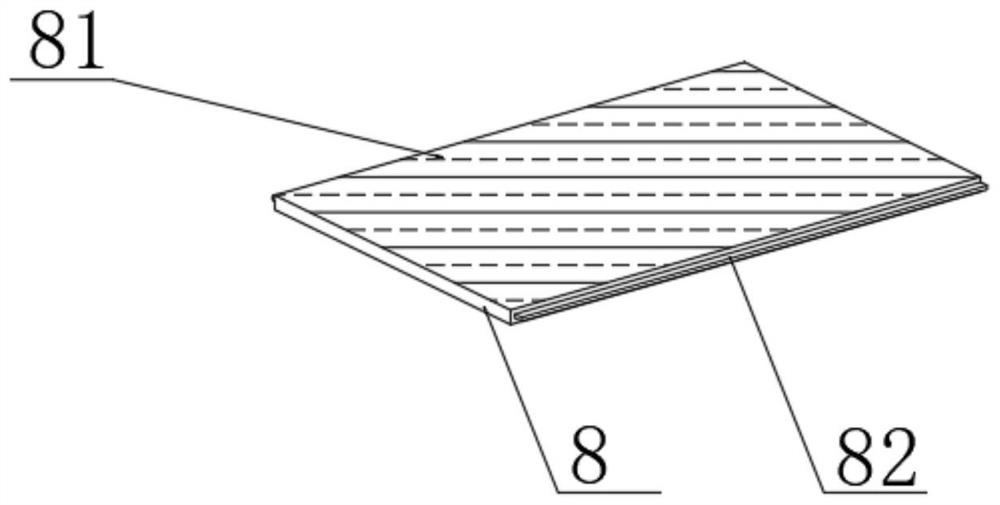

[0038] The upper surface of the palette 8 is provided with a plurality of blind mixing slots, and each of the blind mixing slots is densely provided with deformable flexible soft columns 14, and the height of the flexible soft columns 14 is low. At the depth of the blind mixing notch, and between two adjacent blind notches, a dividing plate 13 is used to separate, and the upper end surface of the dividing plate 13 is flat with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com