Measurement method for depth measurement device for sealed groove

A technology of depth measurement and measurement method, which is applied in the direction of mechanical depth measurement, etc., can solve the problems of inaccurate processing of sealing groove depth, loss of sealing function, wear of sealing ring, etc., to improve measurement accuracy, increase compression resistance, and positioning accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

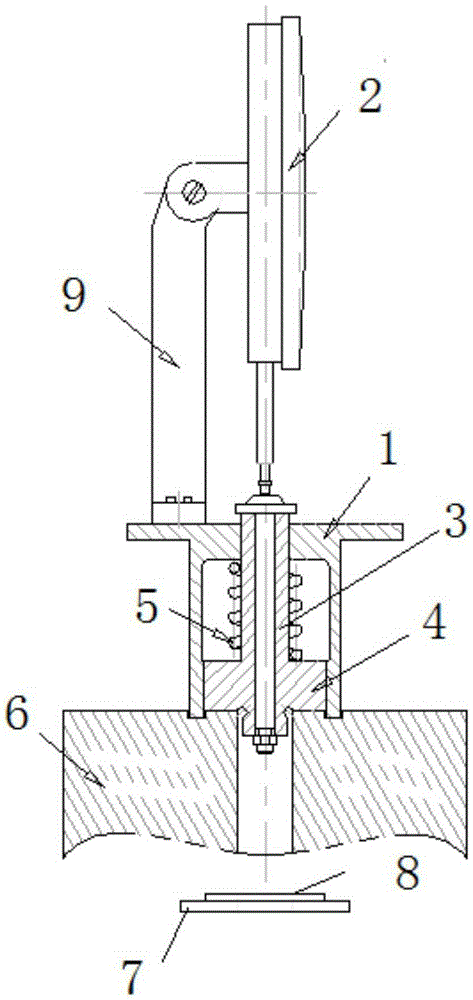

[0012] like figure 1 Shown is a measurement method for a sealing groove depth measuring device. The sealing groove measuring device includes a positioning column 1, a measuring cylinder, and a dial indicator 2. One end of the positioning column 1 is provided with an opening, and the other end of the positioning column 1 is provided with a position on the side of the positioning column 1. The wall is connected as an integral end wall, and a cavity is formed between the opening of the positioning column 1 and the end wall. The measuring cylinder includes a movable rod 3, and a piston body 4 placed in the cavity of the positioning column 1 protrudes from the movable rod 3, and the piston body The inner end face of 4 is connected with the end wall of positioning column 1 by spring 5, and the upper end of movable rod 3 stretches out through the end wall of positioning column 1, and the measuring head of dial indicator 2 is arranged on the protruding end of this movable rod 3. Above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com