Electronic Distortion Coefficient Measuring Instrument for Automobile Shape Measuring System

A technology of shape measurement and distortion coefficient, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of complex distortion parameter models, large amount of calculation, contour and shape bending changes, etc., and achieve simple and fast distortion correction, mechanical The effect of less processing steps and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

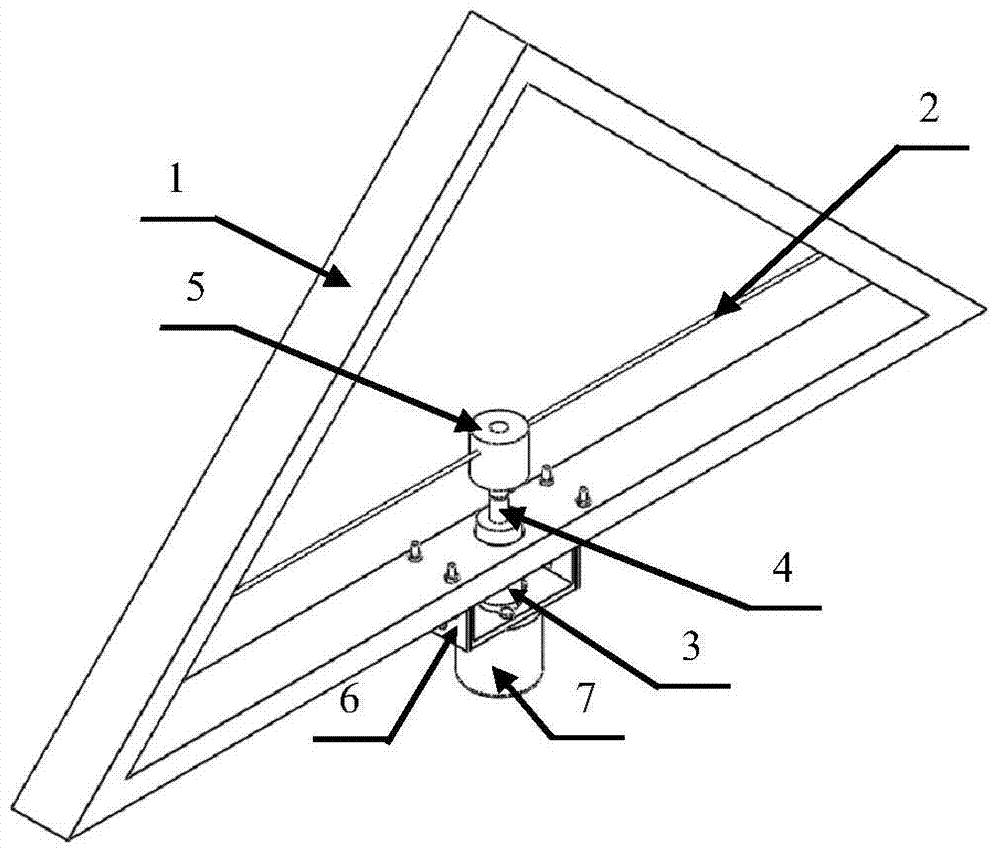

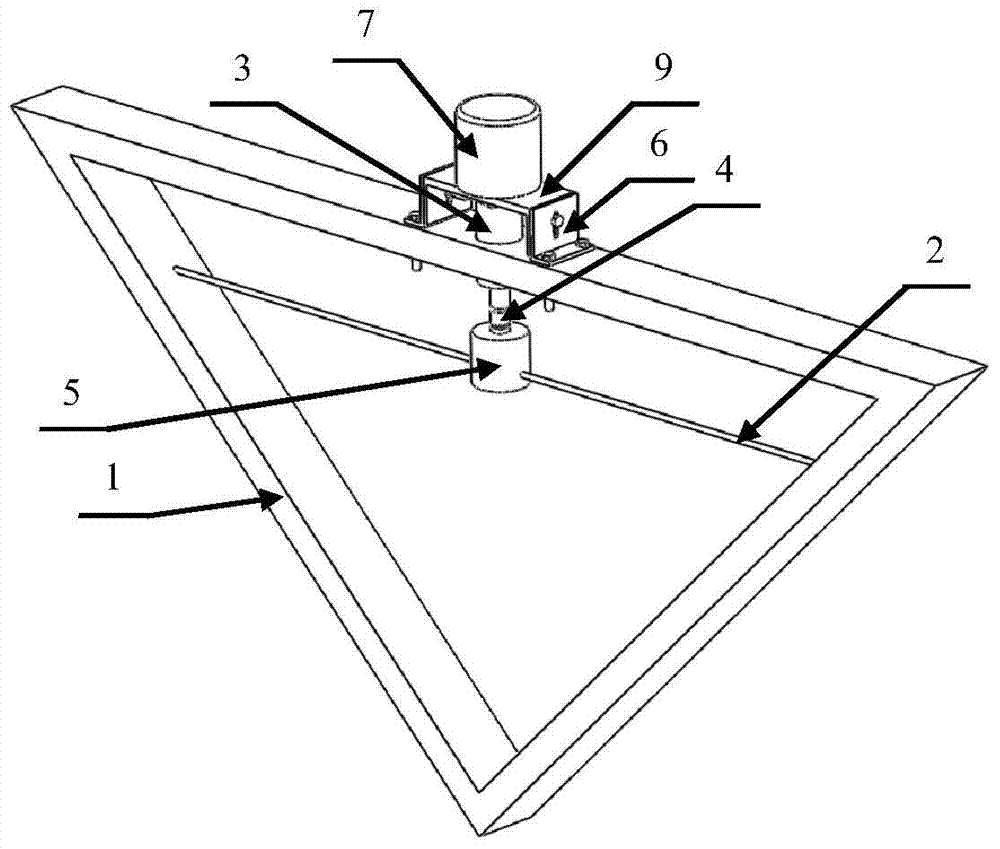

[0026] refer to Figure 1 to Figure 8 , the electronic distortion coefficient measuring instrument of the automobile shape measurement system includes a triangular steel frame 1, a steel wire 2, a long sleeve 3, an adjustment stud 4, a short sleeve 5, an encoder bracket 6, an encoder 7 and a sliding steel sheet 9 .

[0027] The triangular steel frame 1 is a triangular frame welded by square steel. A large circular through hole is processed in the middle part of the bottom edge of the triangular steel frame 1, and four small circular through holes are processed around the large circular through hole.

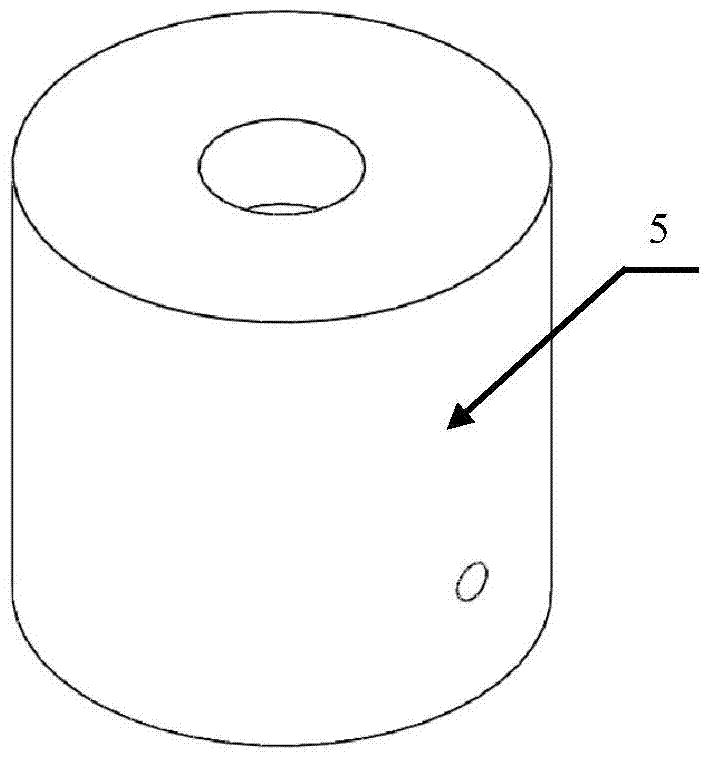

[0028] The short sleeve 5 is a cylindrical steel piece. The short sleeve 5 is processed with a stepped circular hole in the axial direction. The bottom of the short sleeve 5 is processed with a circular through hole in the radial direction. The steel wire 2 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com