Position adjusting-type steering device

A steering device and adjustable technology, applied in steering control, steering mechanism, transportation and packaging, etc., can solve problems such as harsh and abnormal noise, and achieve the effect of suppressing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

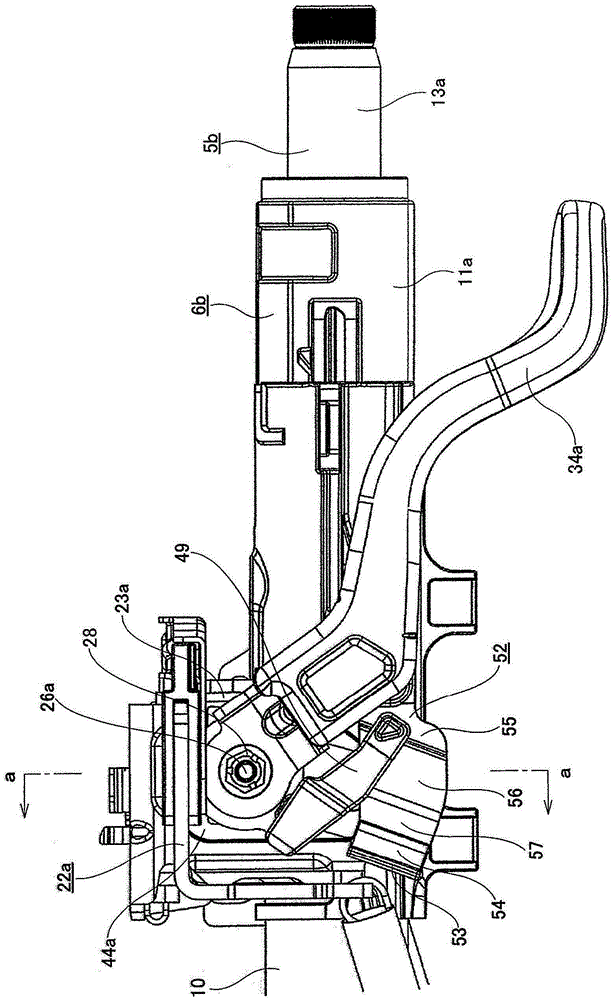

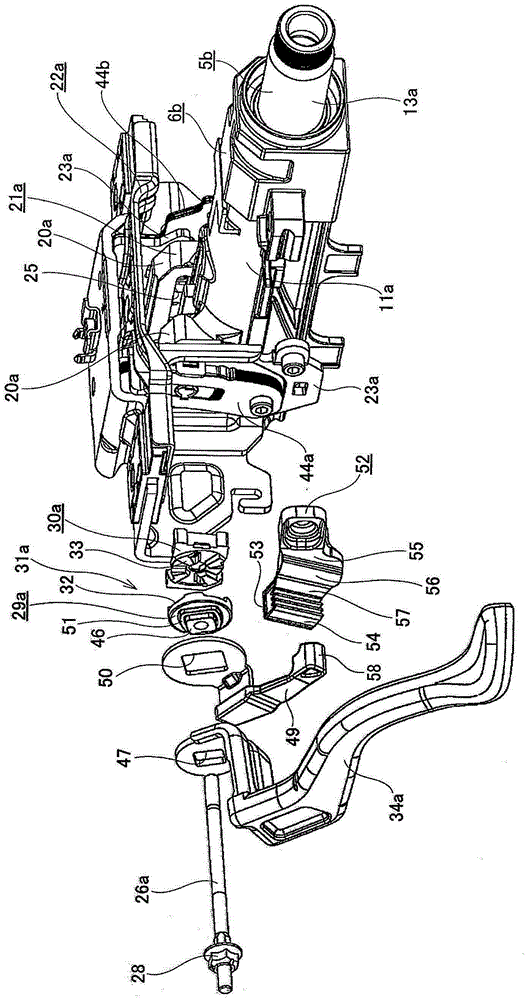

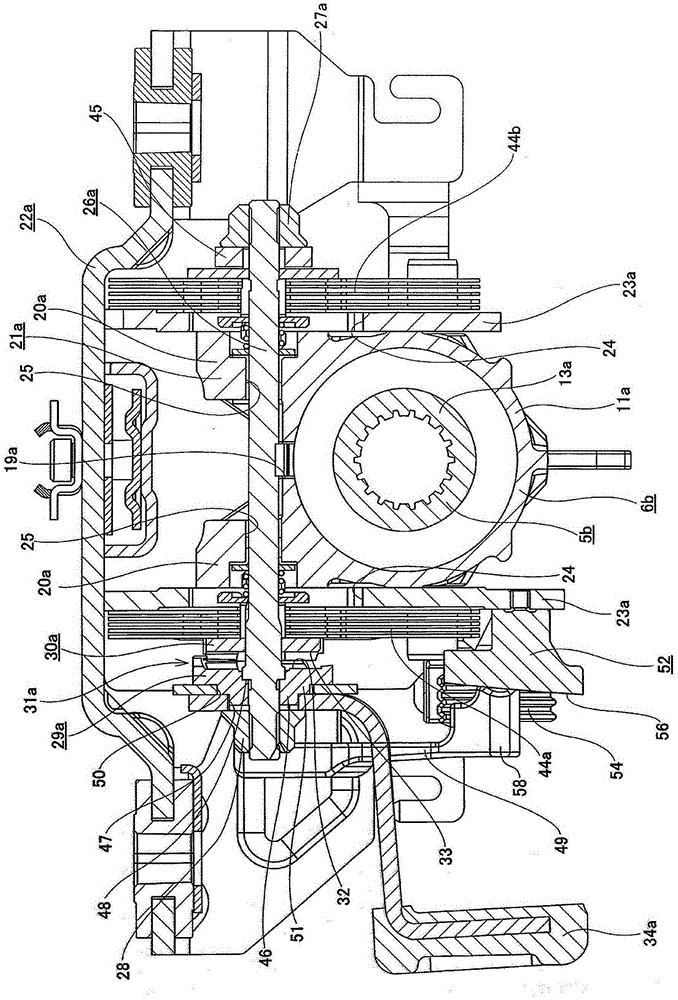

[0119] Figure 1-7The first embodiment of the present invention is shown. In addition, this embodiment is characterized in that an abnormal noise suppression structure (structure including the sub-arm 49, the receiving side member 52, and the buffer member 54) is added for suppressing: When the axial dimension of the cam device 31a is reduced) and rotates, the stepped portions 39, 40 of the two cam surfaces 32, 33 on the driving side and the driven side (refer to Figure 12 ) harsh abnormal noise (metal contact sound) produced by strong contact (collision) with each other. The structure and function of other parts, except for one part, are the same as the above-mentioned Figure 10-12 The shown conventional structures are basically the same, therefore, overlapping illustrations and descriptions are omitted or simplified, and the following description will focus on the characteristic parts of this embodiment and the parts different from the above-mentioned conventional struct...

no. 2 Embodiment approach

[0137] Figure 8 The second embodiment of the present invention is shown. In this embodiment, when adjusting handle 34a (for example, refer to Figure 4 , 5 ) is turned downward in the unlocked state, the front end portion 58 of the sub-arm 49 comes into contact with the flat portion 57a of the receiving side member 52a in a state where a preload is applied due to the elastic deformation of the sub-arm 49 . Thereby, in the unlocked state, it is possible to reliably prevent the adjustment lever 34a from rattling in the width direction.

[0138] Also in this embodiment, since the flat portion 57 is provided with the stroke s behind the flat surface 59a of the sub-arm 49 that is in contact with the buffer member 54, the inclination can be adjusted smoothly.

[0139] The other configurations and functions are the same as those of the above-mentioned first embodiment, and therefore redundant illustrations and descriptions are omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com