Production method of oxidatively curable alkyd-modified silicone-acrylic copolymer

A technology of silicone acrylic copolymer, which is applied in the direction of coating, etc., can solve the problems of weather resistance, decrease of coating film strength, slow drying, etc., and achieve the effect of high initial gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

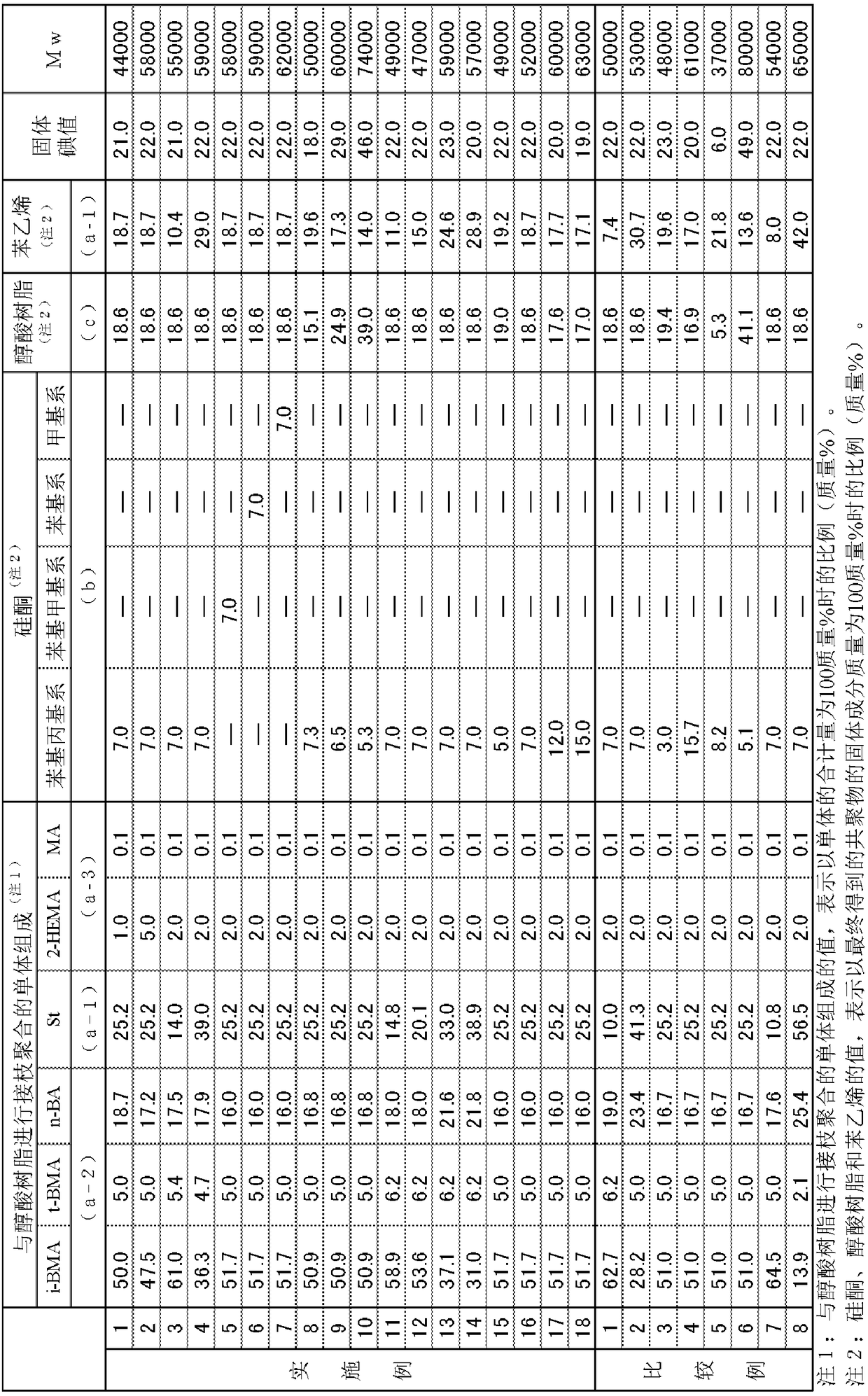

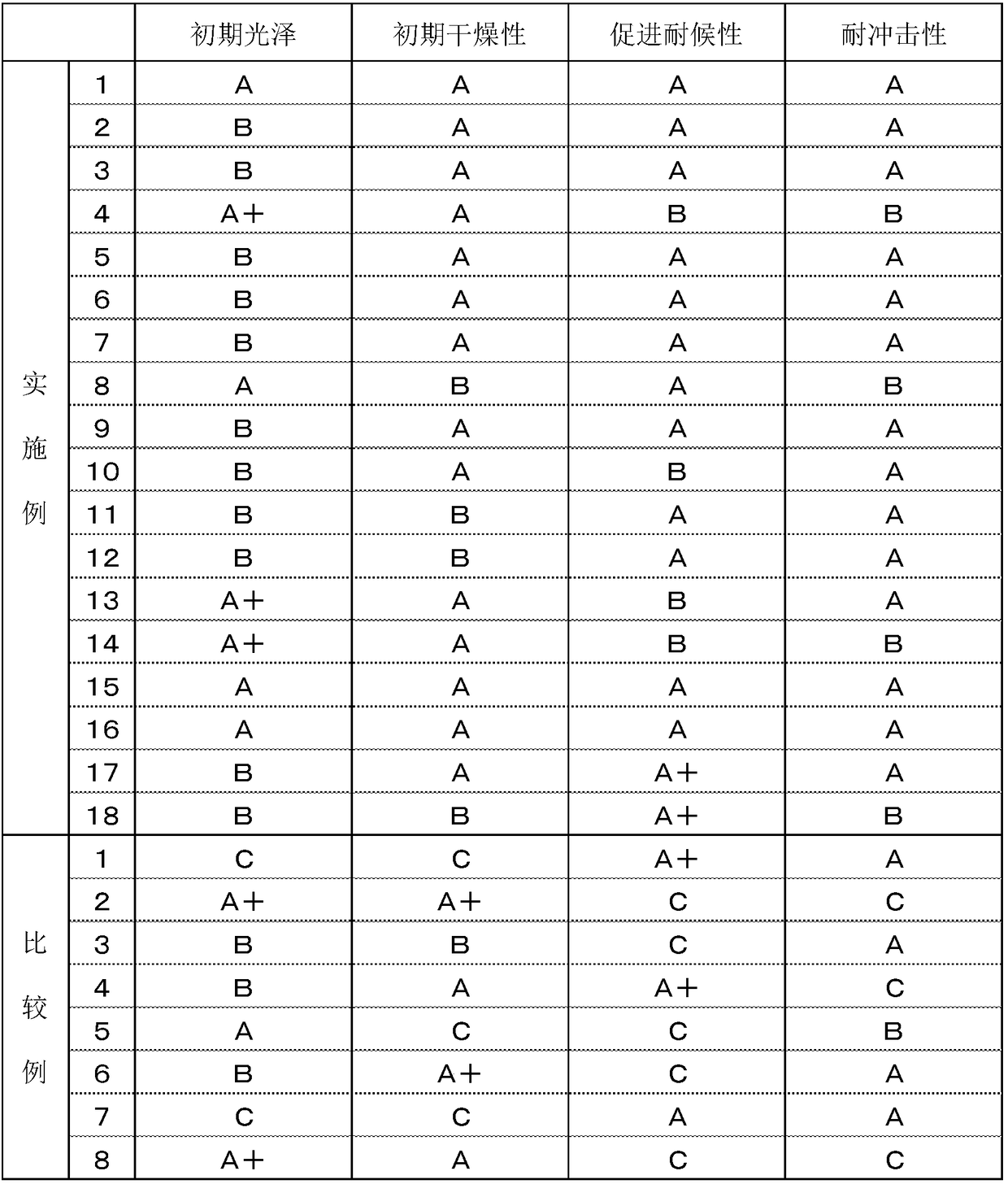

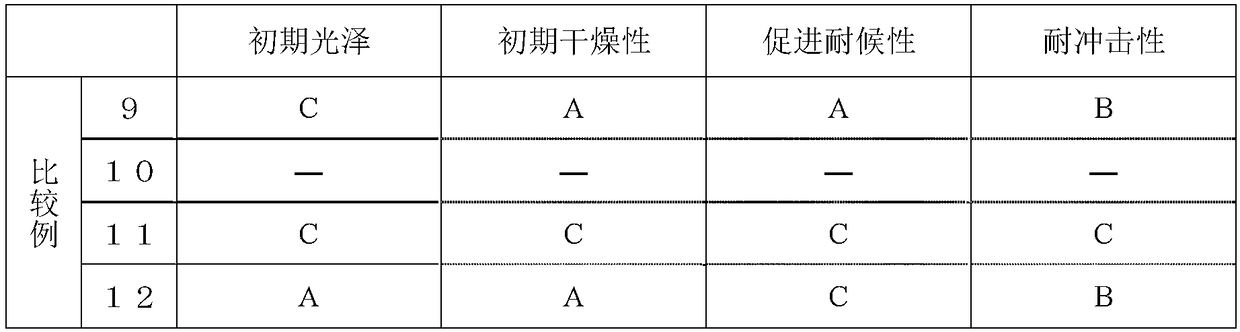

[0116] Hereinafter, although an Example and a comparative example are given and this invention is concretely demonstrated, this invention is not limited to these Examples.

Synthetic example

[0117] (Synthesis example: Synthesis of alkyd resin)

[0118] The following raw materials were added to the reaction vessel, the temperature was raised to 240° C., and the reaction was carried out until the acid value was 5 or less while removing moisture in the reaction system with a water separator. When the acid value was 5 or less, xylene was removed by distillation under reduced pressure. After cooling, the obtained reactant was diluted with 350 parts by mass of petroleum spirit to obtain an oil content of 50%, an acid value of 2.5, a viscosity (Gardner bubble viscometer / 25°C) Z, a color number (Gardner) of 6, and a non-volatile content of 60% by mass. alkyd resin.

[0119] Phthalic anhydride: 140 parts by mass

[0120] Dehydrated castor oil fatty acid: 260 parts by mass

[0121] Glycerin: 50 parts by mass

[0122] Pentaerythritol: 70 parts by mass

[0123] Reflux solvent (xylene): 15.6 parts by mass

Embodiment 1

[0125]

[0126] 17.53 parts by mass of the alkyd resin (60% by mass of non-volatile content) and 31.78 parts by mass of petroleum spirit obtained in the above synthesis example were put into a reaction vessel, stirred while blowing nitrogen gas, and heated to 120°C. Next, the mixture shown below was dropped into the reaction vessel over 2 hours while maintaining the temperature at 120°C. In addition, the ratio in parentheses shows the ratio of each monomer when the total amount of monomers is 100 mass %.

[0127] (mixture)

[0128] Isobutyl methacrylate: 21.24 parts by mass (50.0% by mass)

[0129] Tert-butyl methacrylate: 2.12 parts by mass (5.0% by mass)

[0130] n-butyl acrylate: 7.95 parts by mass (18.7% by mass)

[0131] Styrene: 10.70 parts by mass (25.2% by mass)

[0132] 2-Hydroxyethyl methacrylate: 0.43 parts by mass (1.0% by mass)

[0133] Methacrylic acid: 0.04 parts by mass (0.1% by mass)

[0134] tert-hexyl peroxyisopropyl monocarbonate: 0.46 parts by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com