Cosmetic composition for sustaining luster

A technology of composition and cosmetics, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems of easy damage of cosmetic film, reduced skin luster, thick cosmetic film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of Examples and Comparative Examples

[0033] According to the ingredients and contents (% by weight) described in Table 1 below, a water-in-oil type cosmetic was prepared by the following preparation method.

[0034]

[0035] 1) The oil phase ingredients are mixed and heated to 80°C, and then dispersed.

[0036] 2) The colorant ingredients are mixed and stirred in the above 1).

[0037] 3) Slowly heat the water phase ingredients to 80°C in a separate water phase tank and dissolve completely.

[0038] 4) The water phase component of the above 3) is slowly added to the oil phase component of the above 1), and emulsified using a homomixer.

[0039] 5) After the emulsification is completed, defoam and cool to 28°C.

[0040] [Table 1]

[0041]

experiment example 1

[0042] Experimental Example 1: A water-in-oil cosmetic formulation comprising an oil phase polymer

[0043] In order to confirm the initial gloss and long-lasting effect of the water-in-oil type cosmetic composition containing the oil phase polymer for smoothing the makeup film, experiments were carried out on the above-mentioned Examples and Comparative Examples.

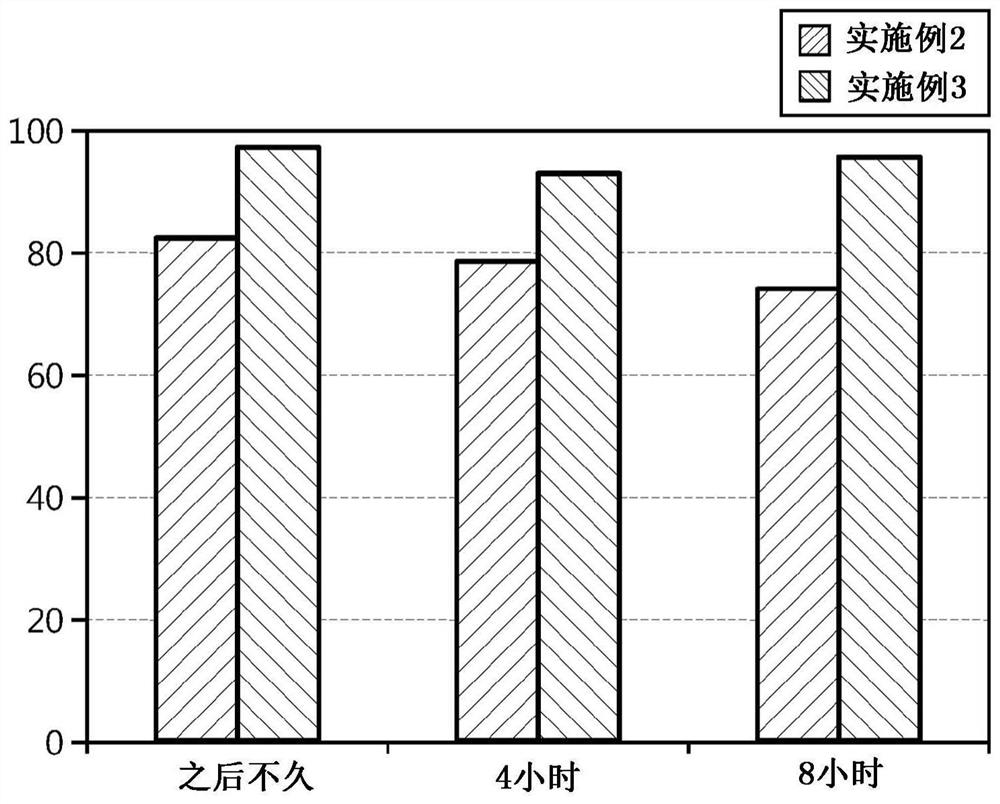

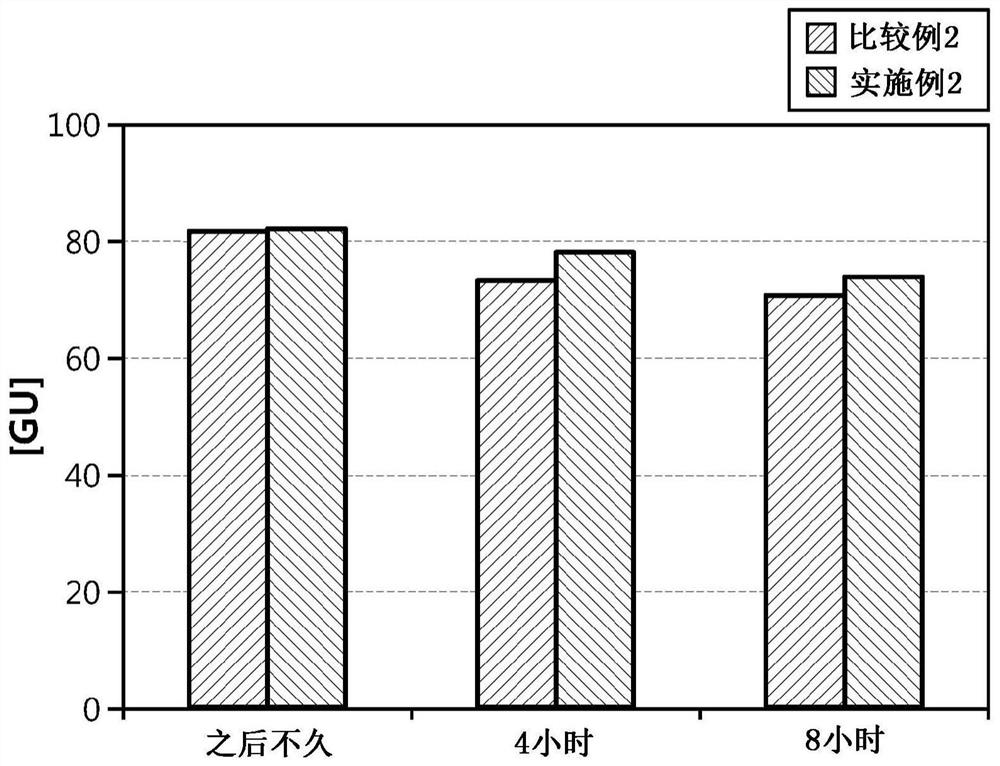

[0044] The moisture test of the water-in-oil cosmetics of the above-mentioned Examples 2 and 3 was carried out. For run-off measurement, the dosage forms are spread to a thickness of 60 μm on black and white paper and then measured using a gloss meter (Glossmeter VG 2000, 85°). As for the measurement method, the gloss was measured three times immediately after application and after 4 hours and 8 hours, and the average value thereof was used to represent the initial gloss and the reduction rate of gloss. figure 1 The case is to compare the GU* values obtained by the gloss meter according to time, and Table 2 show...

experiment example 2

[0048] Experimental Example 2: A water-in-oil cosmetic formulation containing a water-phase polyol

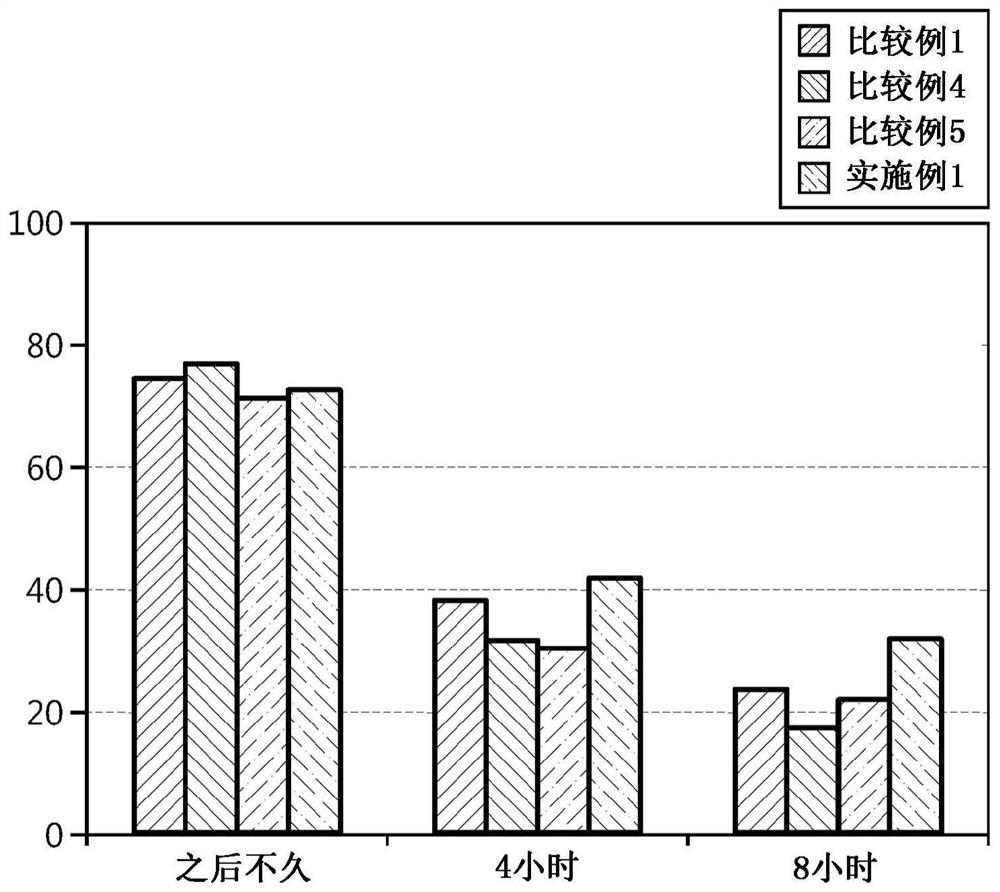

[0049] In order to confirm the initial gloss and long-lasting effect of applying a polyol having a high refractive index to a water-in-oil type cosmetic composition in a water phase, the formulations of Examples and Comparative Examples in the above Table 1 were prepared and experiments were performed. Gloss meter measurements where high refractive polyols are applied to formulations that do not contain high refractive oils are shown in figure 2 , The gloss reduction rate is shown in Table 3.

[0050] [table 3]

[0051] Gloss reduction rate (%) Comparative example 1 Comparative example 4 Comparative Example 5 Example 1 Reduction rate (4 hours) 48.64 58.66 57.68 42.38 Reduction rate (8 hours) 68.32 77.68 69.43 55.83

[0052] From figure 2 From the results shown in Table 3, it can be confirmed that the water-in-oil cosmetics containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com