Mounting structure for an electric motor

A technology for mounting structures and motors, applied in electromechanical devices, electrical components, electrical components, etc., can solve problems such as unsuitability for motors, increased manufacturing workload, etc., to increase operational safety and service life, improve vibration behavior, and reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

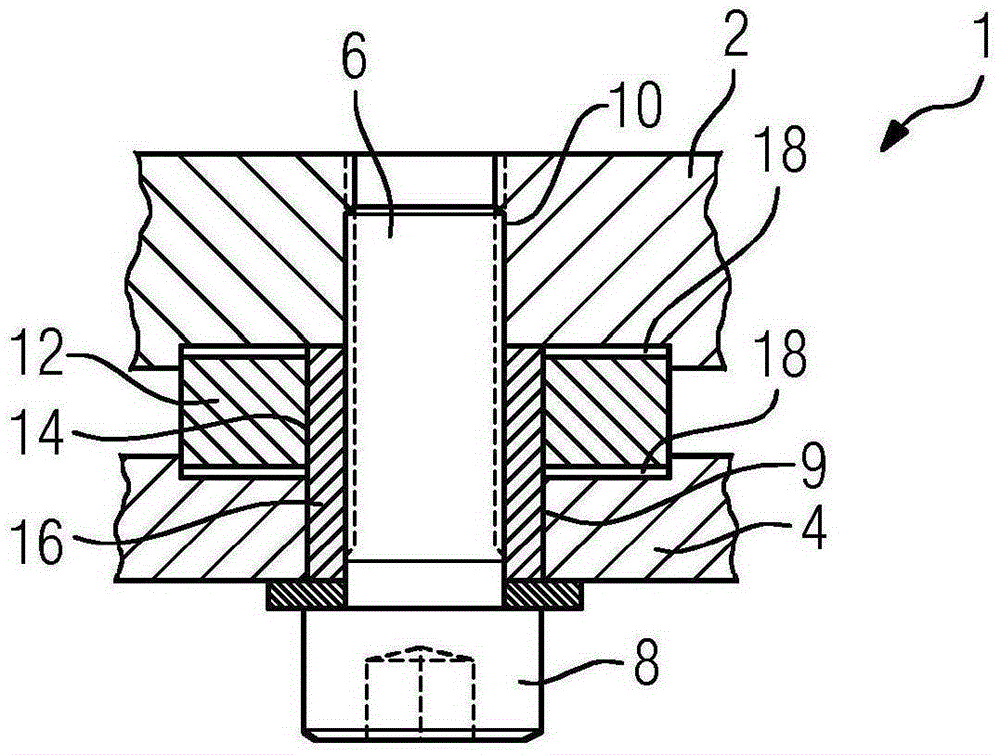

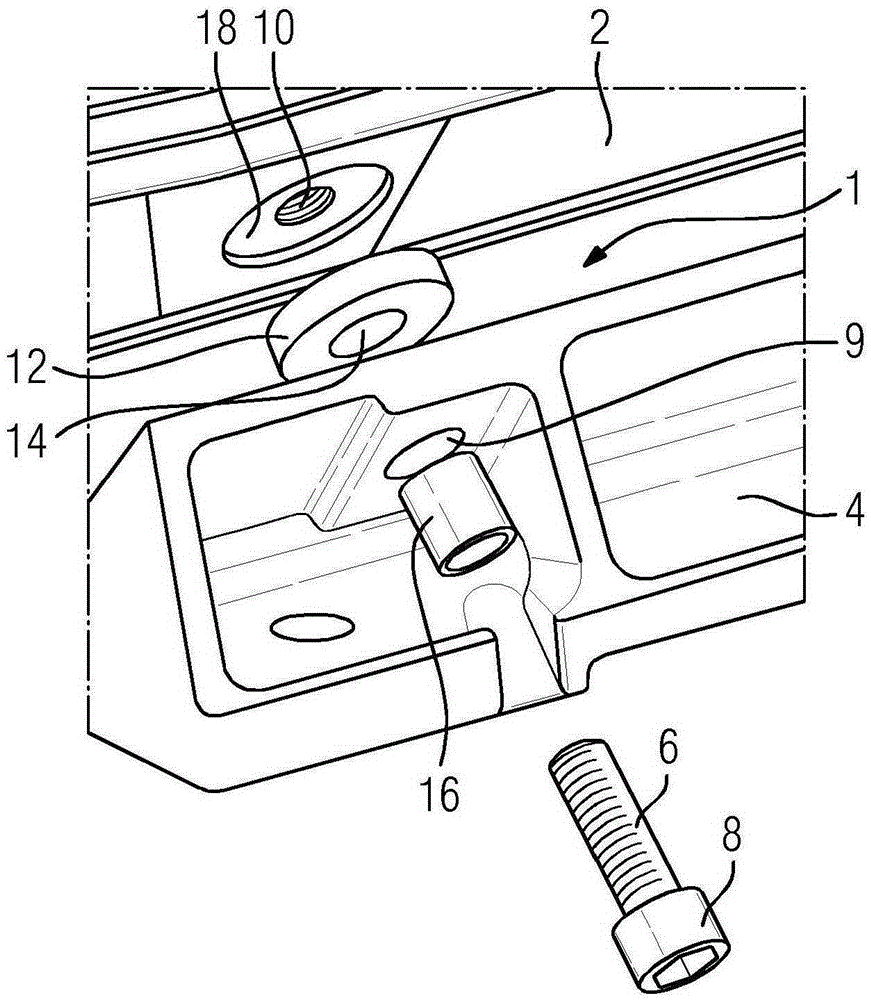

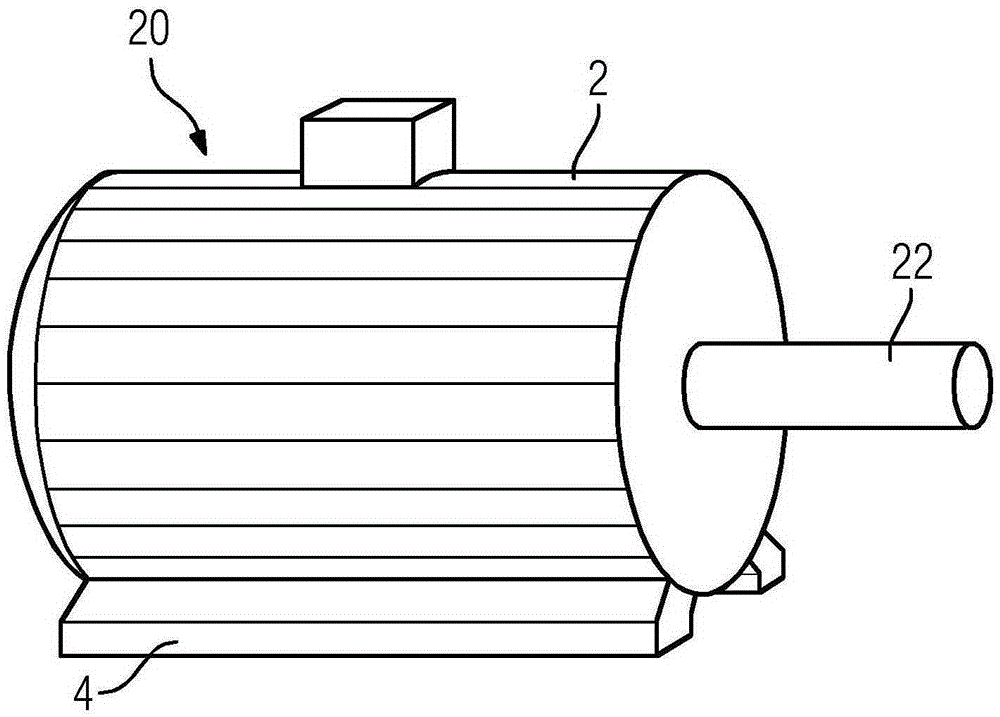

[0026] figure 1 A cross-sectional view of a mounting structure 1 for an electric motor, in particular a squirrel-cage electric motor, is shown. The installation structure 1 connects the fixed frame 2 with the base 4 through screws 6 . The screw 6 has a cylindrical shape and a screw head 8 with a larger diameter than the body of the screw 6 . The body of the screw 6 has an external thread (not shown). The screw 6 penetrates a hole 9 in the base 4 , which has a smaller diameter than the screw head 8 of the screw 6 , and the screw 6 is screwed into a threaded hole 10 in the frame 2 .

[0027] The general structure of a squirrel cage motor has been described. Owing to the alternating electromagnetic forces, vibrations will occur, especially in squirrel-cage motors with two magnetic poles. In order to reduce these vibrations, a partition 12 made of elastic material is placed between the frame 2 and the base 4 . The elastic material can consist, for example, of rubber.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com