Supporting frame

A technology on a support frame and a support frame, which is applied in the field of support frames, can solve the problems of inconvenient operation for employees, easy dumping of storage boxes, and easy falling on the ground, etc., and achieves the effect of saving space, reliable and stable placement, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

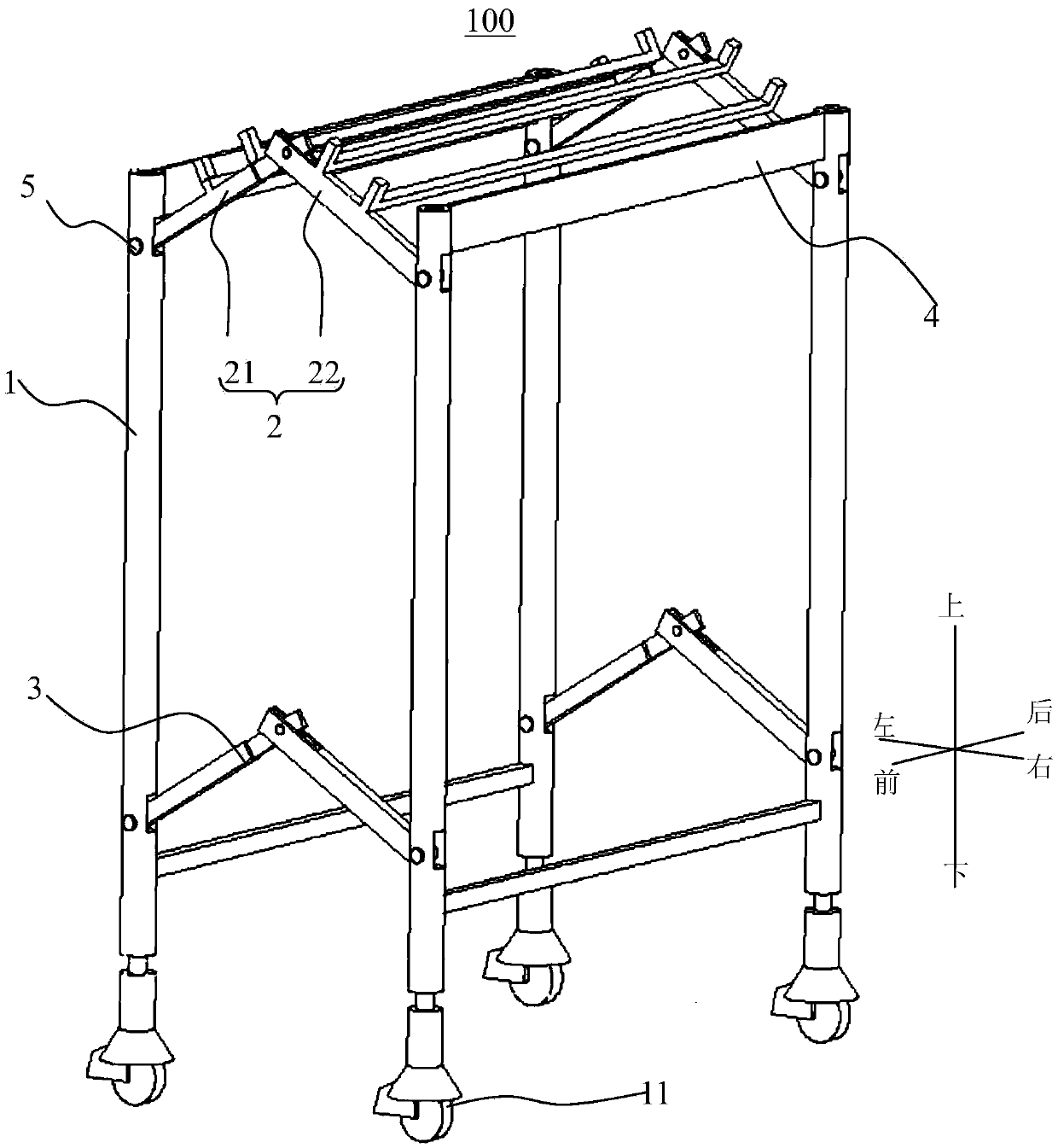

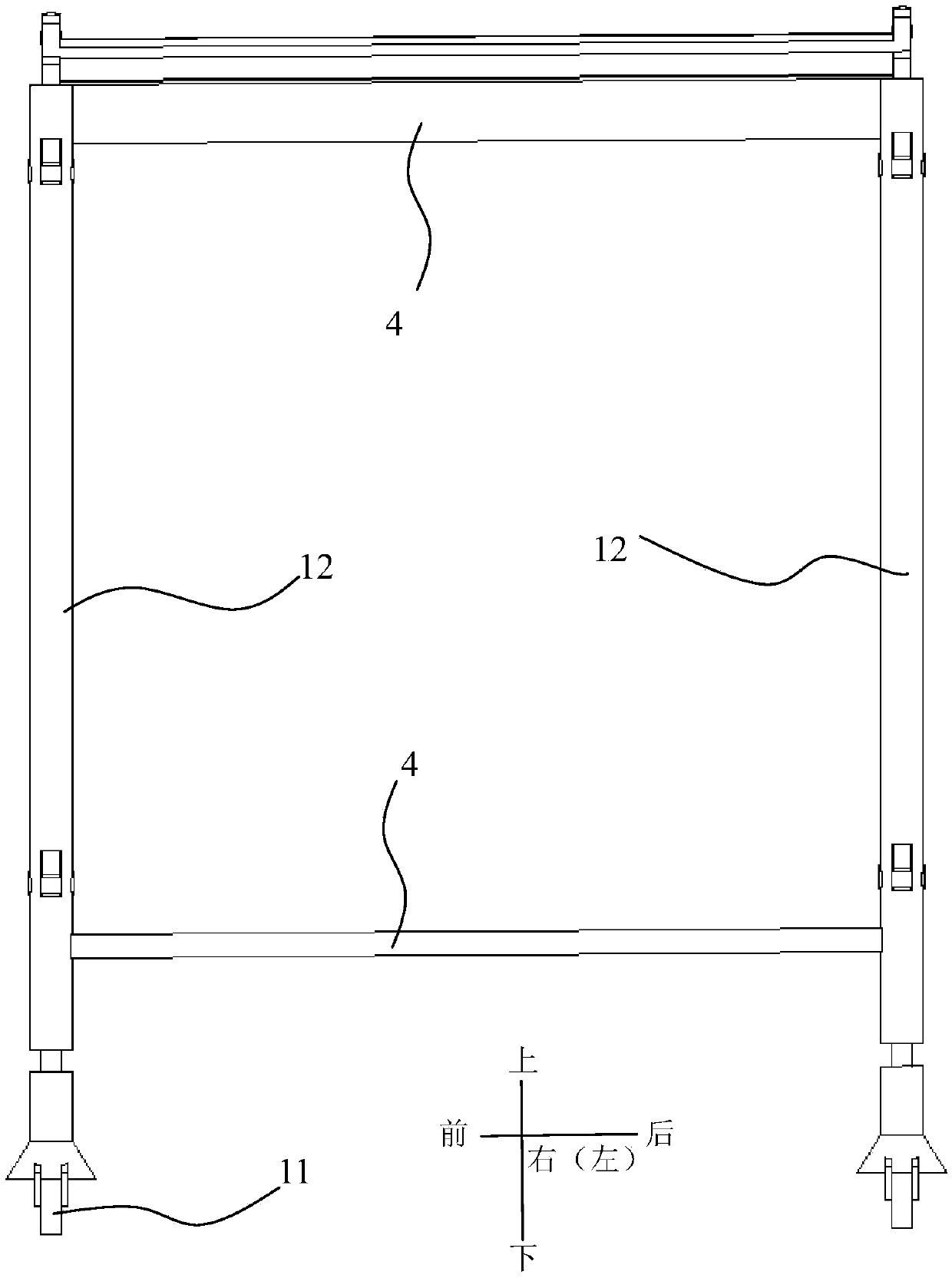

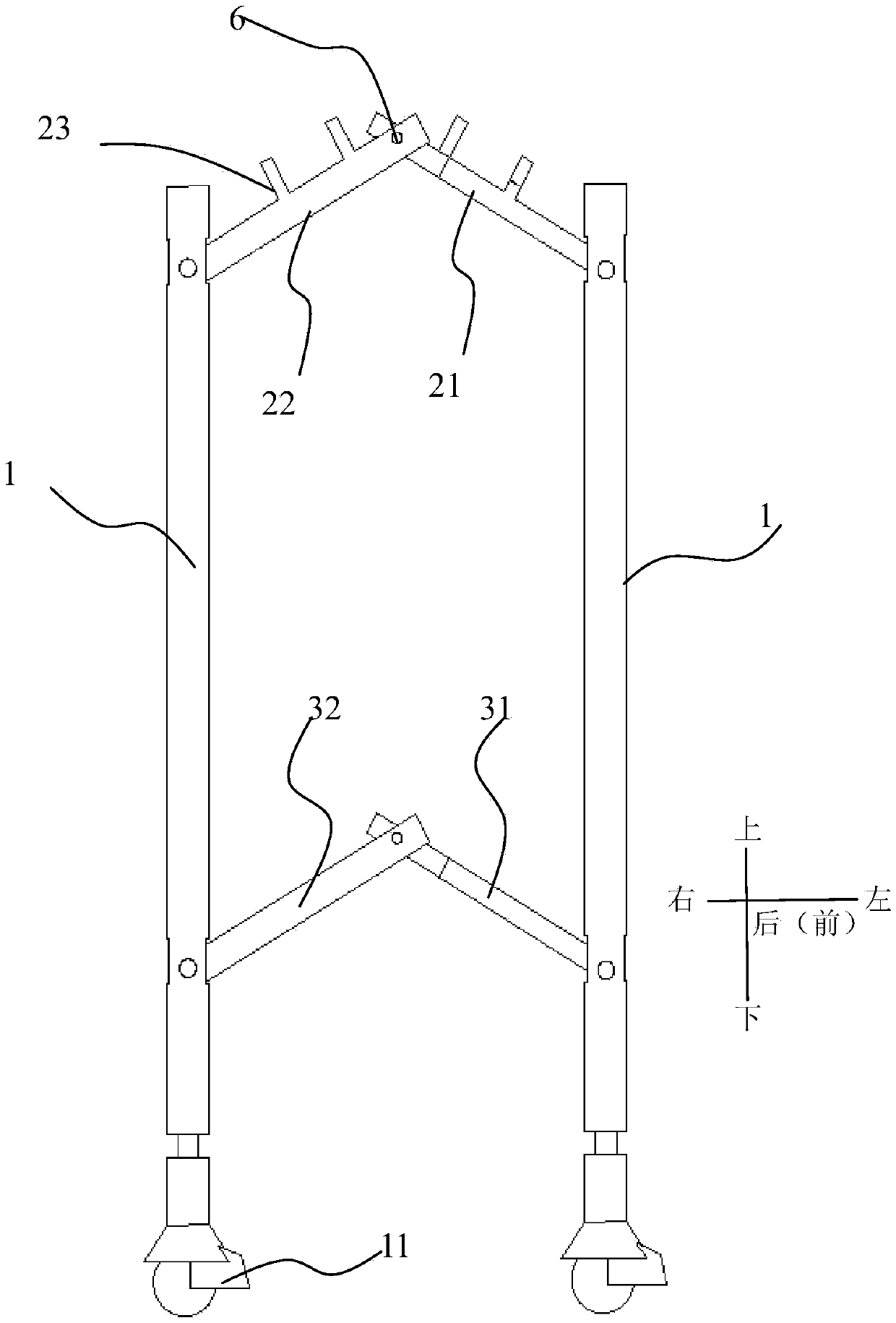

[0059] Such as Figure 1-Figure 3 As shown, the supporting frame 100 in this embodiment may include two supporting frames 1 , a placing part 2 and a stabilizing part 3 arranged oppositely. Wherein, the placing part 2 can be used for placing goods and the like.

[0060] Specifically, two brackets 1 are arranged at intervals. Each support 1 comprises two vertical rods 12, which are connected by connecting rod 4 between the two vertical rods 12, and the bottom of each vertical rod 12 is provided with a universal wheel 11 with self-locking function, each universal Wheels are movably mounted on the vertical rod 12 up and down. The connecting rod 4 is a horizontal rod.

[0061] The placing part 2 is respectively connected with the vertical rods 12 of the two brackets 1 . The placement part 2 has a storage position and an unfolded position, in terms of, as figure 1 with image 3 As shown, the placing part 2 includes a first connecting part 21 and a second connecting part 22 rot...

Embodiment 2

[0066] The supporting frame in this embodiment may include two supporting frames and a placing part arranged oppositely. Wherein, the placing part can be used for placing goods and the like.

[0067]Specifically, two brackets are arranged at intervals. Each support includes two vertical rods, which are connected by connecting rods. The bottom of each vertical rod is provided with a universal wheel with self-locking function, and each universal wheel can move up and down. on a vertical pole. The connecting rod is a horizontal rod.

[0068] The placing part is respectively connected with the two vertical rods of the two brackets. The placing part has a storage position and an unfolding position. Specifically, the placing part includes a first connecting part and a second connecting part connected with the first connecting part. A receiving space is provided under the second connecting part. The first connecting part and the second connecting part The two connecting parts are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com