Preparation method of oxide and celadon combined decoration

A preparation process and oxide technology, applied in the direction of decorative art, decorative structure, etc., can solve the problem of single appearance and characteristic shape of porcelain, and achieve infinite charm, unique and novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

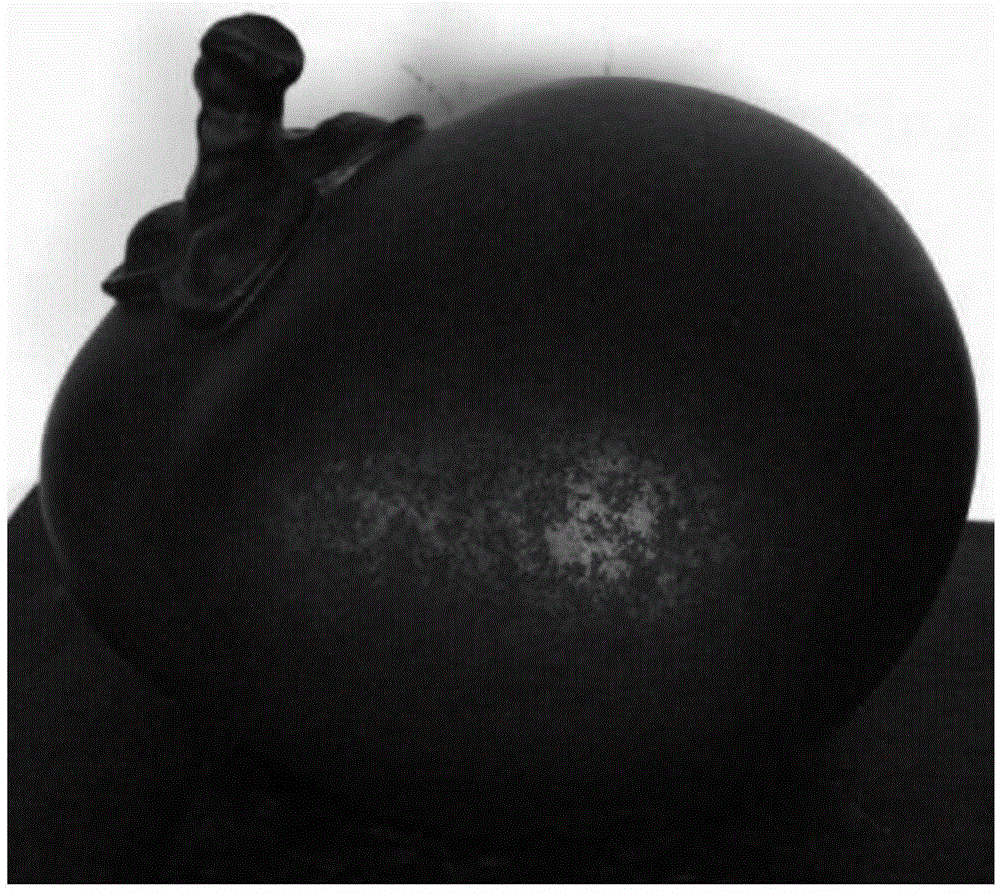

[0047] according to figure 1 As shown, the preparation process of a combination of oxide and celadon decoration described in this embodiment includes the following steps in sequence:

[0048] 1) Forming:

[0049] a. Put the practiced clay on the table and prepare a clean gypsum board;

[0050] b. Use bare hands to knead the mud into small balls, and then spread the small balls of mud on the gypsum board one by one, gradually laying out the bottom layer of the desired shape;

[0051] c. Then gradually superimpose the small lumps of mud in solid layers, and use light pressure to press and superimpose each layer with your fingers until the basic shape is completed;

[0052] d. Use clay sculpture tools to carry out partial pressing to promote the overall part shaping;

[0053] e. If there is a lack of mud in the process, it needs to be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com