Mounting structure and mounting method of fabricated type swastika stone lattice partition wall

An installation structure and prefabricated technology, applied to building components, building structures, walls, etc., can solve problems such as potential safety hazards and poor stability of stone installation, and achieve the effects of avoiding potential safety hazards, improving construction efficiency, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

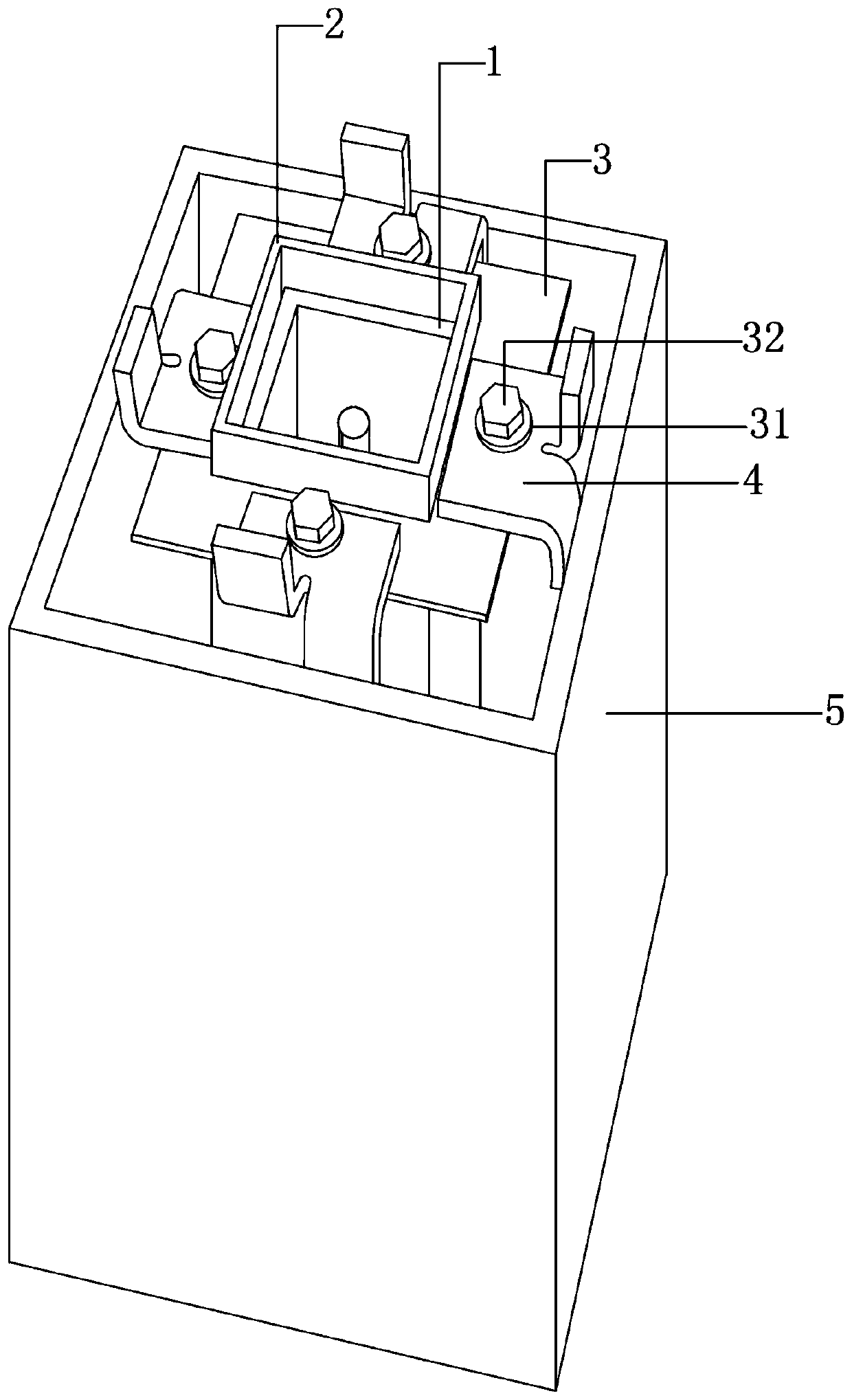

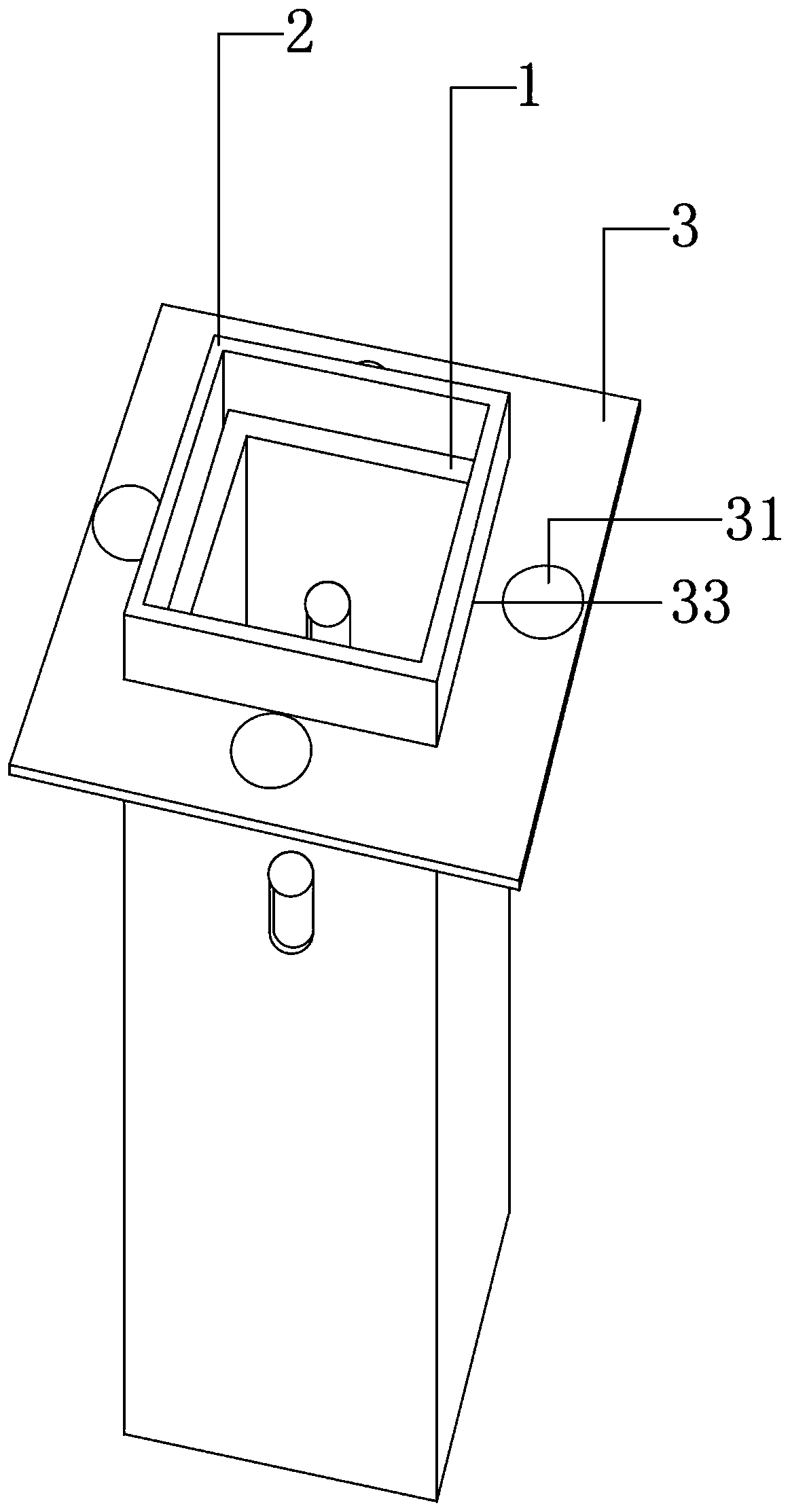

[0036] see Figure 1 to Figure 4 , the figure shows the installation structure of an assembled Wanzifu stone lattice partition provided by Embodiment 1 of the present invention, which is mainly composed of installation pipe 2, side edge plate 3, multiple dry hanging parts 4 and aluminum honeycomb stone parts 5, wherein the side edge plate 3 is a square structure, the side edge plate 3 is set on the installation pipe 2, and at the same time, the inner wall 33 of the through hole of the side edge plate 3 is welded on the outer wall of the installation pipe 2, and a plurality of dry hanging parts 4 are distributed on the periphery of the installation pipe 2, and a plurality of dry hanging parts 4 are fixedly connected to the side edge plate 3, and the end of each dry hanging part 4 extends out of the side edge plate 3 and is fixedly connected to the aluminum honeycomb stone part 5.

[0037] Wherein, specifically, the cross-section of the installation pipe 2 is rectangular, that i...

Embodiment 2

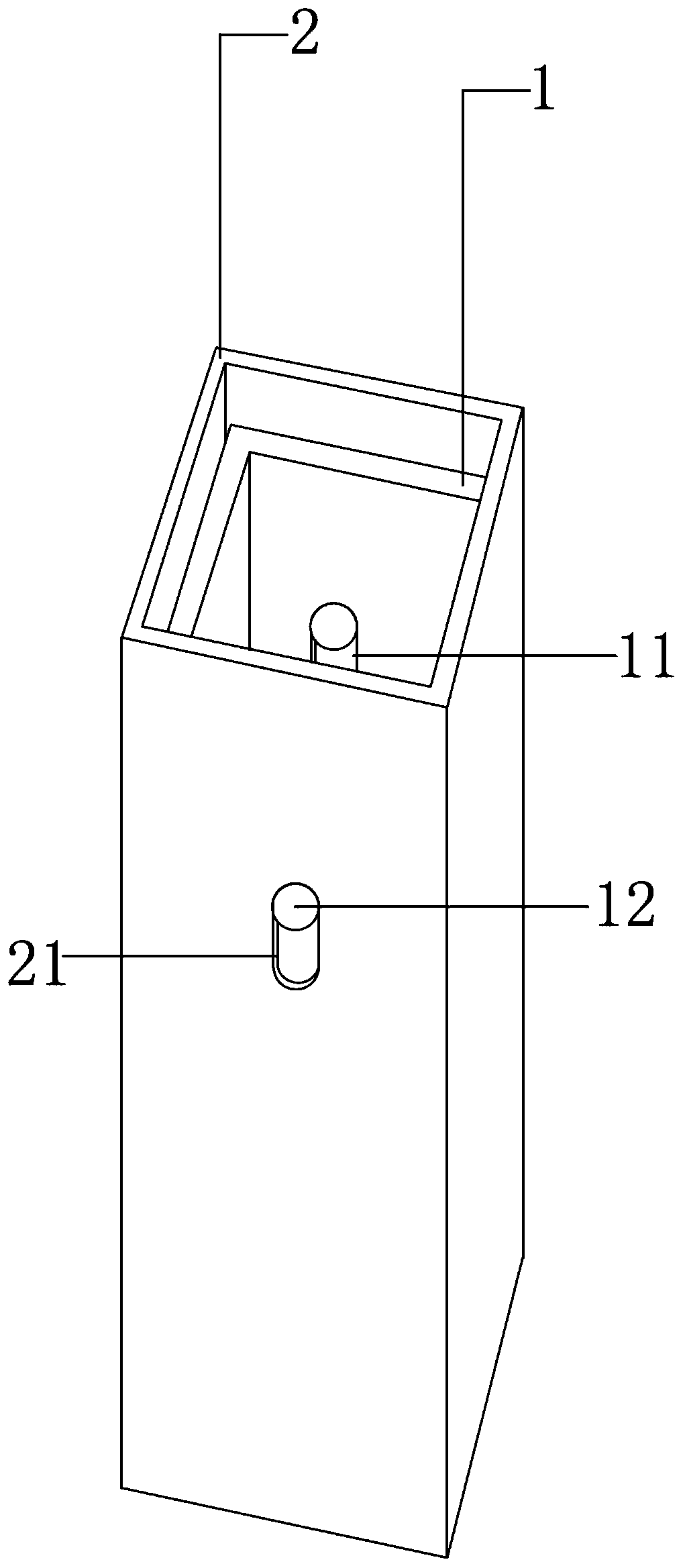

[0045] see Figure 1 to Figure 4 , the figure shows the installation structure of an assembled Wanzifu stone lattice partition provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements : the installation pipe 2 is sleeved on the base shaft 1, and the installation pipe 2 adjusts the position of the installation pipe 2 back and forth along the axial direction of the base shaft 1, wherein the base shaft 1 can be a through pipe, when the installation pipe is a square pipe, The base shaft is preferably also provided as a square tube to accommodate the shape of the mounting tube.

[0046] Specifically, a first waist-shaped hole 21 is opened on the installation pipe 2, a second waist-shaped hole 11 is opened on the base shaft 1, and the first bolt 12 penetrates the first waist-shaped hole 21 and the second waist-shaped hole 11 to install Tube 2 and base shaft 1 a...

Embodiment 3

[0049] see Figure 1 to Figure 4 , the figure shows the installation structure of an assembled Wanzifu stone lattice partition provided by the third embodiment of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments : the dry hanging piece 4 is provided with a first screw hole 41, and the side edge plate 3 is provided with a second screw hole 31, and the second bolt 32 penetrates the first screw hole 41 and the second screw hole 31 to connect the dry hanging piece 4 and the side edge The boards 3 are connected together, so that the quick disassembly and assembly of the dry hanging parts on the side edge boards can be facilitated, thereby improving the installation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com