Impurity removing device for removing iron impurities in feed raw materials

A technology for feed raw materials and impurities, which is applied in the field of impurity removal devices for removing iron impurities in feed raw materials, can solve the problems of large density and volume, poor impurity removal effect, etc., and achieves excellent effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

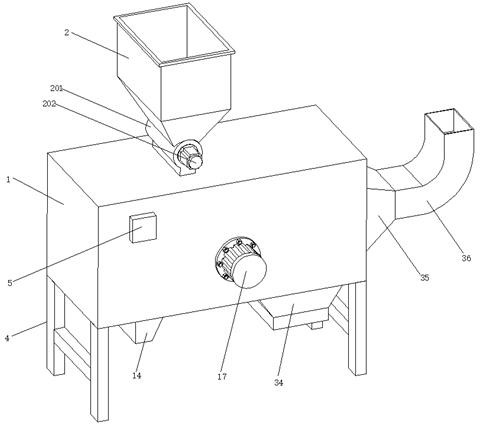

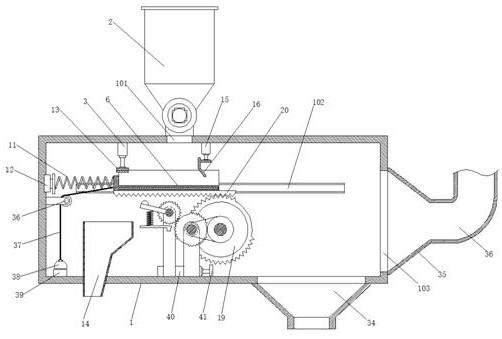

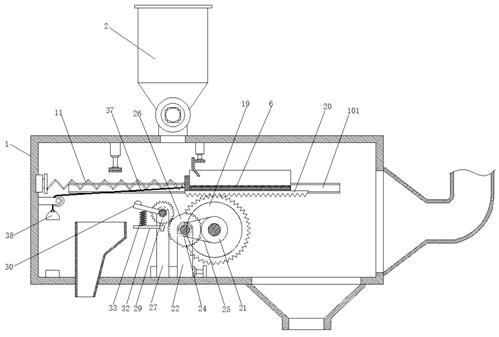

[0038] Embodiment 1 introduces a kind of impurity removal device for removing iron impurities in feed raw materials, referring to the attached figure 1 , attached figure 2 And attached image 3 , its main structure includes a box body 1 and a storage bin 2. A feed inlet 101 is opened in the middle of the upper surface of the box body 1 , and the storage bin 2 is arranged at the feed inlet 101 . Legs 4 are provided at four corners of the lower surface of the box body 1 , and a PLC control box 5 is arranged on the outer surface of the box body 1 . A horizontal chute 102 is provided on the front and rear inner walls of the box body 1 , and a material receiving plate 6 is arranged inside the box body 1 , and the right end of the material receiving plate 5 is arranged below the feeding port 101 .

[0039] Reference attached Figure 4 , attached Figure 5 And attached Figure 6 , permanent magnets 7 are evenly arranged inside the material receiving plate 6, and side plates 8 ...

Embodiment 2

[0044] Embodiment 2 is improved in many aspects on the basis of Embodiment 1, which will be described in detail below.

[0045] The same part of this embodiment 2 and embodiment 1 will not be described again, the difference is that: this embodiment is also provided with a uniform discharge device at the lower end of the storage bin 2, refer to the attached figure 1 And attached Figure 8 , its uniform discharge device includes a cylinder 201 connected with the storage bin 2, the outer end surface of the cylinder 201 is provided with a stepper motor 202, and its stepper motor 202 is connected with the signal output end of the PLC control box 5, and A horizontal rotating rod 203 is connected to the end where the output shaft of the stepping motor 202 extends into the cylinder 201 , and a plurality of baffle plates 204 are uniformly arranged on the outer surface of the horizontal rotating rod 203 . The above setting of the present embodiment 2 controls the stepper motor 202 by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com