Thin type glue-less cotton raw material ratio and mixing method thereof

A non-adhesive cotton and raw material technology, applied in adhesives, textiles and papermaking, non-woven fabrics, etc., can solve the problems of lack of high-end feeling, joint gap, mesh cotton joint gap, etc., to save costs and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

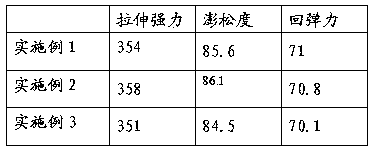

Embodiment 1

[0015] The preparation method of the light and thin non-glued cotton of this embodiment sequentially includes: material selection, opening, carding, oven baking, and molding and packaging.

[0016] Select 70% of polyester staple fiber and 30% of low-melting point fiber for batching, and then mix by multi-layer tiling method to mix and disperse different fibers; then send the mixed batching into the opening machine for opening, opening During the loosening process, the fibers are fully mixed and sent to the cotton box for storage after opening; then the opened fibers are fed from the cotton box to the carding machine for carding, and the feeding amount is controlled according to the product gram weight during carding, and Set the speed of the hair transmission chain to 6m / min-20m / min, and the frequency of reverse wool (10-25) times / min, and automatically feed through the cotton box, which is more conducive to mixing evenly and combing; then the combed The fiber passes through t...

Embodiment 2

[0018] The preparation method of the light and thin non-glued cotton of this embodiment sequentially includes: material selection, opening, carding, oven baking, and molding and packaging.

[0019] Select 80% of polyester staple fiber and 20% of low-melting point fiber for batching, and then mix by multi-layer tiling method to mix and disperse different fibers; then send the mixed batching into the opener for opening, During the loosening process, the fibers are fully mixed and sent to the cotton box for storage after opening; then the opened fibers are fed from the cotton box to the carding machine for carding, and the feeding amount is controlled according to the product gram weight during carding, and Set the speed of the hair transmission chain to 6m / min-20m / min, and the frequency of reverse wool (10-25) times / min, and automatically feed through the cotton box, which is more conducive to mixing evenly and combing; then the combed The fiber passes through the bridge and dir...

Embodiment 3

[0021] The preparation method of the light and thin non-glued cotton of this embodiment sequentially includes: material selection, opening, carding, oven baking, and molding and packaging.

[0022] Select 90% of polyester staple fiber and 10% of low-melting point fiber for batching, and then mix by multi-layer tiling method to mix and disperse different fibers; then send the mixed batching into the opener for opening, During the loosening process, the fibers are fully mixed and sent to the cotton box for storage after opening; then the opened fibers are fed from the cotton box to the carding machine for carding, and the feeding amount is controlled according to the product gram weight during carding, and Set the speed of the wool transmission chain to 6 m / min-20 m / min, and the frequency of reverse wool (10-25) times / min, and automatically feed the material through the cotton box, which is more conducive to mixing evenly and combing; then combing The final fiber passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com